You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cracked cylinder bore

- Thread starter Wee dregor

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

That would have been my next question.A pal of mine had a similar thing - but in his case he had mixed up big end caps - is it possible to put your cap on the wrong way round?

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

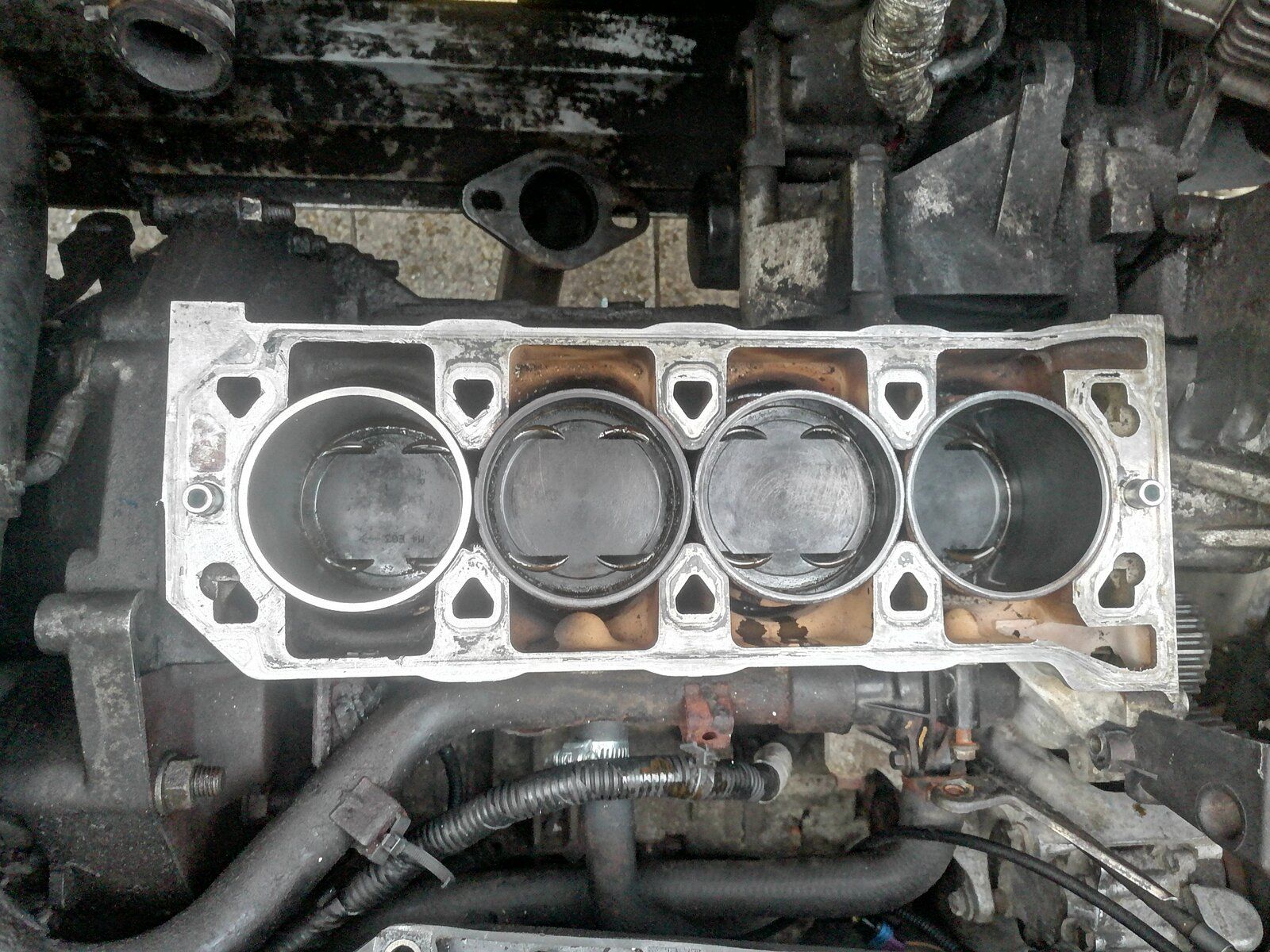

Hi guys thanks for your replies and help I've managed to free the crankshaft I poured a little oil down cap and cylinder liner to try and lubricate the piston it seems that the piston rings were just a little tight against the new liner stopping the crankshaft from turning also when I turned the crank back to its line the liner raised just a tiny bit I've attached a photo with the new liner installed many thanks again!

Attachments

also when I turned the crank back to its line the liner raised just a tiny bit

In that case it needs removing again, and sealing. It's absolutely vital that the liners are clamped when turning the crankshaft, as said right at the beginning of this post.

Any liner movement will allow the coolant into the sump, which is why they must be clamped.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

A clearer picture nodge

I don't know if it's moved or if the crank has brushed the base of the liner causing it to raise minutely as the liner is new it sits deeper through the bore its imbeded and I followed your advice with using the blue hylomar I used a lot to create a good seal on the liner do you think it could have broke its seal with minimil contactIn that case it needs removing again, and sealing. It's absolutely vital that the liners are clamped when turning the crankshaft, as said right at the beginning of this post.

Any liner movement will allow the coolant into the sump, which is why they must be clamped.

- Posts

- 2,103

- Location

- Hertfordshire

Hi, judging by the arrows on the piston crowns it looks like you have a piston in the wrong way, 3 arrows pointing to the right & the one with the new liner pointing to the left (could be wrong as the arrows on 3 of the pistons are very faint.A clearer picture nodge View attachment 271528

I don't know if it's moved or if the crank has brushed the base of the liner causing it to raise minutely as the liner is new it sits deeper through the bore its imbeded and I followed your advice with using the blue hylomar I used a lot to create a good seal on the liner do you think it could have broke its seal with minimil contact

A clearer picture nodge View attachment 271528

I don't know if it's moved or if the crank has brushed the base of the liner causing it to raise minutely as the liner is new it sits deeper through the bore its imbeded and I followed your advice with using the blue hylomar I used a lot to create a good seal on the liner do you think it could have broke its seal with minimil contact

Did you lay the liners side by side to check they were dimensionally identical?

The crank should never touch the liner bottom.

The Hylomar is used sparingly, and only on the bottom register where the liner is pressed into the block by the head.

It must not move once pressed into place, as the Hylomar seal will be damaged.

Oh and as said above, you've go the piston round the wrong way too, as the arrow needs point towards the timing belt end of the engine.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Oh dear looks like

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Looks like it's coming back out thanks for notiticing

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

So after taking the new cylinder liner back out bottom end and cleaning up re inserting with the correct seal applied and re inserting piston in the correct way facing towards camshaft pully, i managed to rebuild engine with head back on. Changed timing belt and water pump after a few non starts after starter motor produced a burning smell at connection so set about starter motor replacement and hey car started with the new head gasket holding so far its been a long journey and couldnt have done it without the help and knowalage of the people of this forum from start to finish and a big massive thanks to nodge for giving me my car back to enjoy again!!!

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Hi after having rebuilt engine after headgasket change and cylinder liner change car was running great for about 2 weeks checking oil coolant levels religiously which were fine. Suddenly no coolant and after inspection it seems coolent is running straight into sump with milky mess. Head Gasket seems fine with no visable leaks or coolent escaping externally car still running albeit milky mess any ideas could it be liner seal or leaky head gasket causing internal escape or has the heat treatment gone on this head any help where to start before stripping down

Head Gasket seems fine with no visable leaks or coolent escaping externally car still running albeit milky mess any ideas could it be liner seal or leaky head gasket causing internal escape or has the heat treatment gone on this head any help where to start before stripping down

I would guess that a leak has developed on the bottom of the liner, where it should be sealed to the block.

The only sure way to prove this is to remove the sump and pressurise the cooling system. A drip should be evident if you wait long enough.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Thanks for your reply that gives me a good start before taking head off again if it is the case that the liner seal has disloged or broken its seal would it be a case off replacing liner againI would guess that a leak has developed on the bottom of the liner, where it should be sealed to the block.

The only sure way to prove this is to remove the sump and pressurise the cooling system. A drip should be evident if you wait long enough.

if it is the case that the liner seal has disloged or broken its seal would it be a case off replacing liner again

No. If you can prove the a liner is leaking where the bottom is sealed to the block, then all you need to do is lift the offending liner and piston. Clean up the liner bottom land, and the mating face of the block, then re-seal with Blue Hylomar and fit the liner again.

One thing to keep in mind, never ever turn the crankshaft while the liners are free to lift (they must be clamped down), or the Hylomar seal with the block will broken, and any shifted liners will need to be re-sealed.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Thanks will have a strip down over the next few days i was hoping to not have to take head of and disturb gaskets but looks like its a re do job to re seal the liner properly again

potus

Well-Known Member

- Posts

- 2,163

- Location

- South Devon

The joy's of this K series engine, it's amazing that some manufacturers can regularly produce an engine design which rarely suffer this type of problem, Rover obviously failed with this design (yes I know the odd few are reliable)

Good luck with your next round of repairs, I would have sold it long ago.

Good luck with your next round of repairs, I would have sold it long ago.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

The joy's of this K series engine, it's amazing that some manufacturers can regularly produce an engine design which rarely suffer this type of problem, Rover obviously failed with this design (yes I know the odd few are reliable)

Good luck with your next round of repairs, I would have sold it long ago.

The K series engine was and still is an amazing piece of design work.The joy's of this K series engine, it's amazing that some manufacturers can regularly produce an engine design which rarely suffer this type of problem, Rover obviously failed with this design (yes I know the odd few are reliable)

Good luck with your next round of repairs, I would have sold it long ago.

If it is built properly, with the correct components, then it lasts really well. Unfortunately many engines left the factory built to less than perfect standards, which this design simply doesn't tolerate.

Wee dregor

Member

- Posts

- 46

- Location

- Edinburgh

Looks like ive found the problem a small pin sized crack between the liner and bottom end feeding oil sump with coolant other than stripping down from head i took sump out and can see clearly a drip of coolent in piston chamber between new liner its hard to tell if its between liner or not could a spot weld fix this any ideas other than taking liner out again and disturbing gaskets as engine running

Attachments

Similar threads

- Replies

- 26

- Views

- 4K

- Replies

- 0

- Views

- 715