Hello All,

my first two posts on this website were both questions - hopefully my third will be more contributory than the previous, although there will definitely be questions along the way!

We've recently purchased a 2A, and what started life as a 'rolling resto' has inevitably turned into something more. I have shipwrights disease and inevitably there's loads of stuff I didn't spot when I bought it due to being a first time buyer of landies, so likely to be a fairly thorough rebuild of the top half before it next gets an MOT. First place to start is bulkhead...

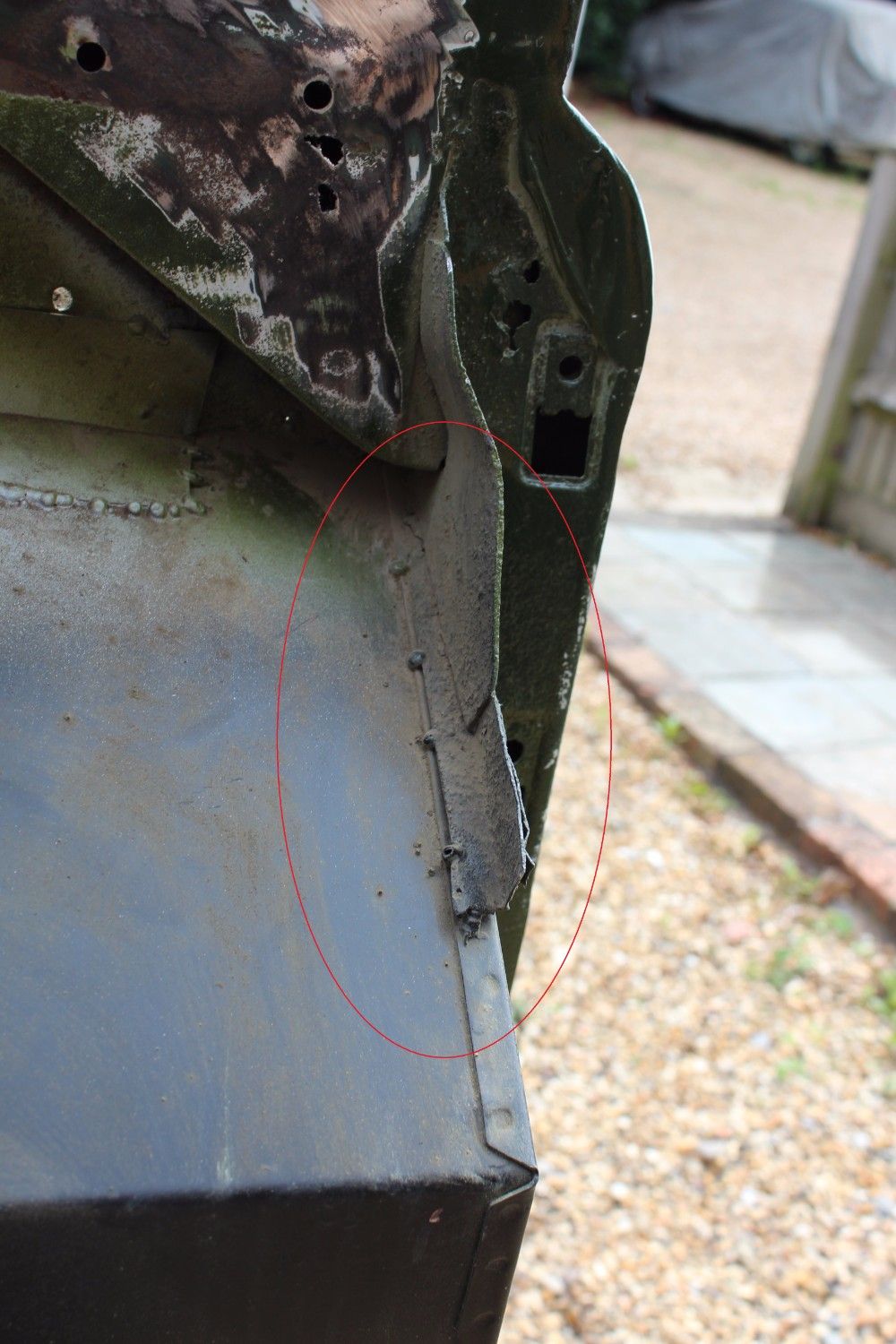

I've discovered that the bottom of the pillars/feet on the bulkhead are a combination of both completely shot and truly bodged by the PO. Frankly I'm embarrassed to have bought it without noticing this - so I'm going to make amends by attempting to repair it. And I'll put the progress reports in this thread

If it all goes horribly wrong I'll end up buying a new bulkhead but I'm going to give repairing it a good bash before I accept defeat. I've welded before but definitely an amateur, so will likely be doing lots of 'test' pieces before I dive in.

As I say, the bottom 1/3 of the pillar downwards is definitely shot and so we will be getting replacement sections for both pillars and feet. What I wasn't sure about was how far up the damage went - I had a horrible feeling there was a lot of filler up there, and when I removed the bolts holding the hinges on the retainer nuts were rusty as it gets - so I didn't hold out much hope.

Last weekend I took a grinder and flapper disc to the sides of the bulkhead, and was pleasantly surprised by what I found at the top of it - shiny metal (underneath a reasonable amount of filler)! The passenger side pillar appears to have had an argument with a tree at some point, so although not as rusty as feared the metal bit isn't the right shape and so filler has been used to make it look right... So the current plan (up for discussion here - suggestions please!) is as follows:

#1 New driver footwell - passenger footwell has been done by PO and isn't dreadful, some small patches top/bottom required. Driver footwell is a patchwork quilt so will drop in a new one.

#2 Likely next job is to repair the upper sections of the bulkhead using sheet and fabrication; from my initial inspection whole repair panels up here are probably not necessary (but advice welcome!) - does depend a bit of what I find underneath the outer skin. If all is not too bad, I think it should just be flat sheet so hopefully not too painful(!) In attached photos I've outlined the areas in red that I'm likely to replace. I'll also fit new captive nuts for the wing mountings at the same time and do as much as I can to protect the internal faces from future rust.

#3 Remove old pillars and replace on both sides - I've seen some previous posts including nice techniques including nuts/bolts to make sure everything aligns, but I'm sure this will require lots of thought before going near a grinder.

#4 Replace pillar feet - scariest bit for me! Haven't thought this through much yet - at this point hoping it will be clearer once I've got new pillars in! Dreading getting it wrong and the whole thing being wonky.

Does this sound like a sensible order to do things? I think I'm right in saying it's best to do these with the bulkhead on the vehicle so that everything lines up and fits properly? Once I'm done I'm thinking I'll remove the bulkhead from the chassis and then do a full clean up and repair other sections that look dodgy. Has anyone ever dipped their bulkhead to strip it? On the one hand it's the only way I can think of to ensure all the cavities are cleaned out, but also aware it might cause other issues I haven't thought of?

Having stripped the bits of interest off last weekend, I then covered them back up with some galvanising primer I've bought to protect it against the weather in the mean time. Next step is to order repair sections (and a welder, likely to keep it simple and go gas MIG) and find the next free weekend - so likely to be a few weeks before the next update.

Wow - wall of text. I've hopefully attached some photos so you can see more clearly what I'm on about - including one of what it looked like just before I took the grinder to it.

my first two posts on this website were both questions - hopefully my third will be more contributory than the previous, although there will definitely be questions along the way!

We've recently purchased a 2A, and what started life as a 'rolling resto' has inevitably turned into something more. I have shipwrights disease and inevitably there's loads of stuff I didn't spot when I bought it due to being a first time buyer of landies, so likely to be a fairly thorough rebuild of the top half before it next gets an MOT. First place to start is bulkhead...

I've discovered that the bottom of the pillars/feet on the bulkhead are a combination of both completely shot and truly bodged by the PO. Frankly I'm embarrassed to have bought it without noticing this - so I'm going to make amends by attempting to repair it. And I'll put the progress reports in this thread

If it all goes horribly wrong I'll end up buying a new bulkhead but I'm going to give repairing it a good bash before I accept defeat. I've welded before but definitely an amateur, so will likely be doing lots of 'test' pieces before I dive in.

As I say, the bottom 1/3 of the pillar downwards is definitely shot and so we will be getting replacement sections for both pillars and feet. What I wasn't sure about was how far up the damage went - I had a horrible feeling there was a lot of filler up there, and when I removed the bolts holding the hinges on the retainer nuts were rusty as it gets - so I didn't hold out much hope.

Last weekend I took a grinder and flapper disc to the sides of the bulkhead, and was pleasantly surprised by what I found at the top of it - shiny metal (underneath a reasonable amount of filler)! The passenger side pillar appears to have had an argument with a tree at some point, so although not as rusty as feared the metal bit isn't the right shape and so filler has been used to make it look right... So the current plan (up for discussion here - suggestions please!) is as follows:

#1 New driver footwell - passenger footwell has been done by PO and isn't dreadful, some small patches top/bottom required. Driver footwell is a patchwork quilt so will drop in a new one.

#2 Likely next job is to repair the upper sections of the bulkhead using sheet and fabrication; from my initial inspection whole repair panels up here are probably not necessary (but advice welcome!) - does depend a bit of what I find underneath the outer skin. If all is not too bad, I think it should just be flat sheet so hopefully not too painful(!) In attached photos I've outlined the areas in red that I'm likely to replace. I'll also fit new captive nuts for the wing mountings at the same time and do as much as I can to protect the internal faces from future rust.

#3 Remove old pillars and replace on both sides - I've seen some previous posts including nice techniques including nuts/bolts to make sure everything aligns, but I'm sure this will require lots of thought before going near a grinder.

#4 Replace pillar feet - scariest bit for me! Haven't thought this through much yet - at this point hoping it will be clearer once I've got new pillars in! Dreading getting it wrong and the whole thing being wonky.

Does this sound like a sensible order to do things? I think I'm right in saying it's best to do these with the bulkhead on the vehicle so that everything lines up and fits properly? Once I'm done I'm thinking I'll remove the bulkhead from the chassis and then do a full clean up and repair other sections that look dodgy. Has anyone ever dipped their bulkhead to strip it? On the one hand it's the only way I can think of to ensure all the cavities are cleaned out, but also aware it might cause other issues I haven't thought of?

Having stripped the bits of interest off last weekend, I then covered them back up with some galvanising primer I've bought to protect it against the weather in the mean time. Next step is to order repair sections (and a welder, likely to keep it simple and go gas MIG) and find the next free weekend - so likely to be a few weeks before the next update.

Wow - wall of text. I've hopefully attached some photos so you can see more clearly what I'm on about - including one of what it looked like just before I took the grinder to it.