dollydisco

New Member

- Posts

- 184

- Location

- kidlington ,oxford

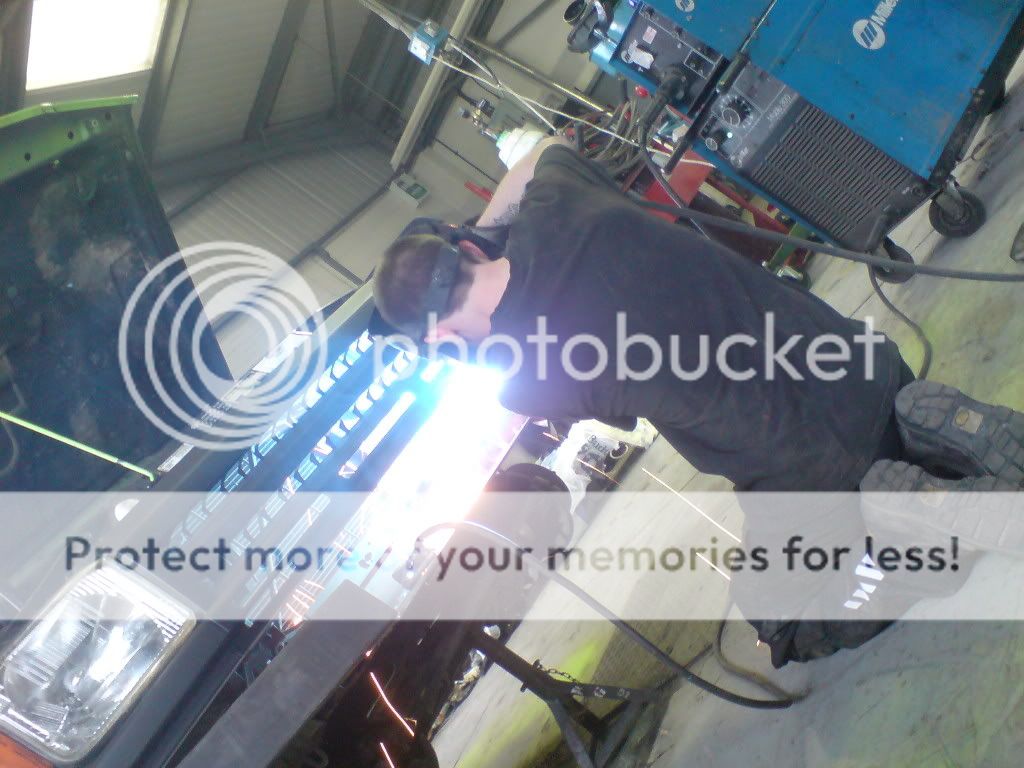

more pictures of the rear fuel tank frame etc,the fuse block for the battery etc and my rear speakers back in!

tis some good news thenhi guys,sorry i havent been on for a while,been working stupid hours!! will upload my recent pictures when i get home later.BUT i have some news for everyone thinking of bobtailing or tray backing a vehicle.

as i write and i quote.all this information has been given to me by VOSA and there website.

Any vehicle that has beed radically altered from its original spec. i.e bobtailing or tray backing .does NOT need an sva test,if the vehicle is an amateur build. i.e you can prove you have done all the work yourself, then it requires an IVA (individual vehicle approval)

as i have retained the original engine,suspension,brakes,axles and steering i score more then 8 point on the iva test scale,therefore i enter the loop hole, because it is an amateur build and i have retained 90% of the original vehicles structure,it will NOT be assigned a q plate, if the test station can prove that the vehicle has been modified using only new materials then it CAN retain its original registration mark OR will be assigned a dated registration plate. I.E the same year (mine being M) but the last numbers and letter will be different) so to answer all your questions. it does not need an sva test,just an IVA because its an amateur build and the vehicle is already registered and being used on the road before the modifications began. i hope that has cleared up an confusion in the matter.

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!