A little bit more today.

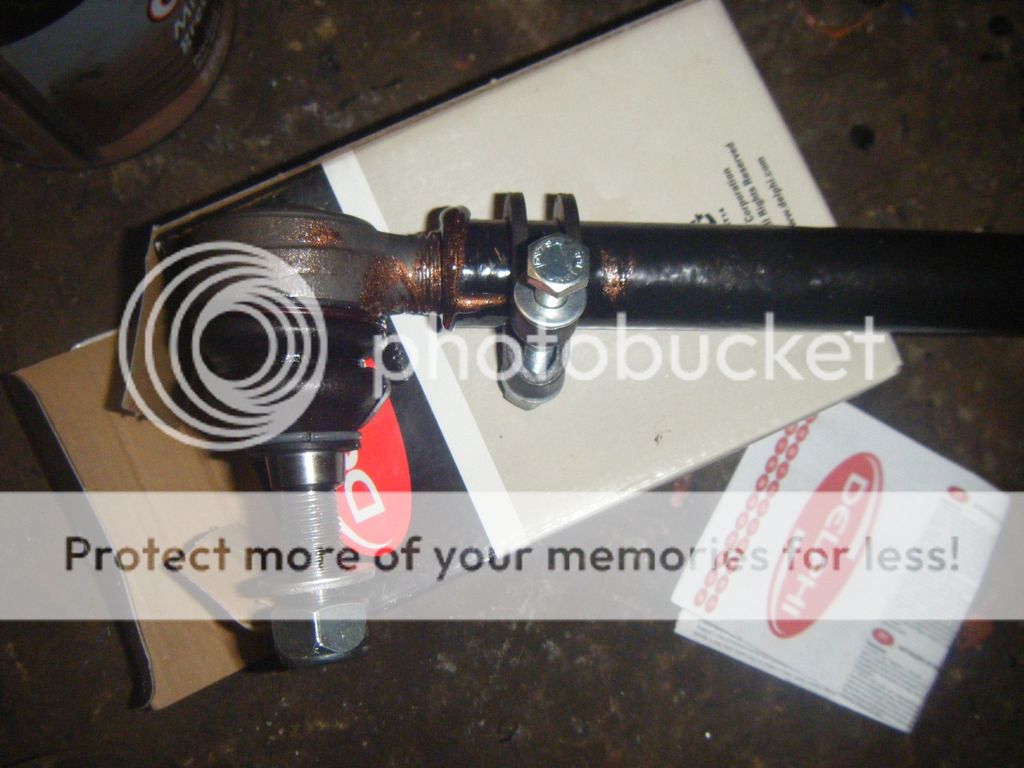

Mainly building the rear axle up.

Forgot to take too many pictures to start with, but stub axles on, new bearings and seal in hubs, new discs (I fitted drilled and grooved, I don't know why, just saw them and thought, ah I'll buy some of them) calipers fitted and new pads.

Put new studs in the casing and fitted the diff, and half shafts.

I then had to get some wheels out the shed to get it rolling, these have probably been in their for the last 6 years or so, not constantly, they have been on a few vehicles over the years, but I think I will use them on this build, seen as the ones that came with it where ****'e, or use the tyres at least, I wouldn't mind a set of mach 5's or sawtooths, but we'll see later in the build.

I was going to leave it like above for the time-being and start the front, but thought I might as well just finish it properly. One job at a time and all that.

So I fitted the galv spring seats and retainers, plus new springs, and made a couple of brake pipes.

Can't say brake pipes are my favourite job, can just never seem to get them perfectly how I want them, but they're acceptable.

Rubber lined p-clips, much better than plastic crap they fit at factory.

And I found some all metal push fit 90's for the breathers.

Paint was still softer than I thought, so I've got some touching up to do though..

Need to have a tidy in the garage first thing tomorrow and will then start on the front axle.

And you know I said I need to ring Richards' chassis this week to try and get an update, well I went on my emails earlier and I had an email from them on Wednesday saying that my chassis is ready and to contact them to arrange collection, they also say they have been trying to contact me since before Christmas numerous times by phone and no answer

Well I've had no missed calls

and had I known I would have collected it asap, as I'd rather have it and not need it than not have it and need it.

Anyway, I gave them a call as soon as I saw it and have organised collection for next Saturday. Can't wait

Maybe things will start falling into place now.