greyhair

Well-Known Member

- Posts

- 1,303

- Location

- IN MY SHED

Very nice I'm after a rear axle is you have one of the to

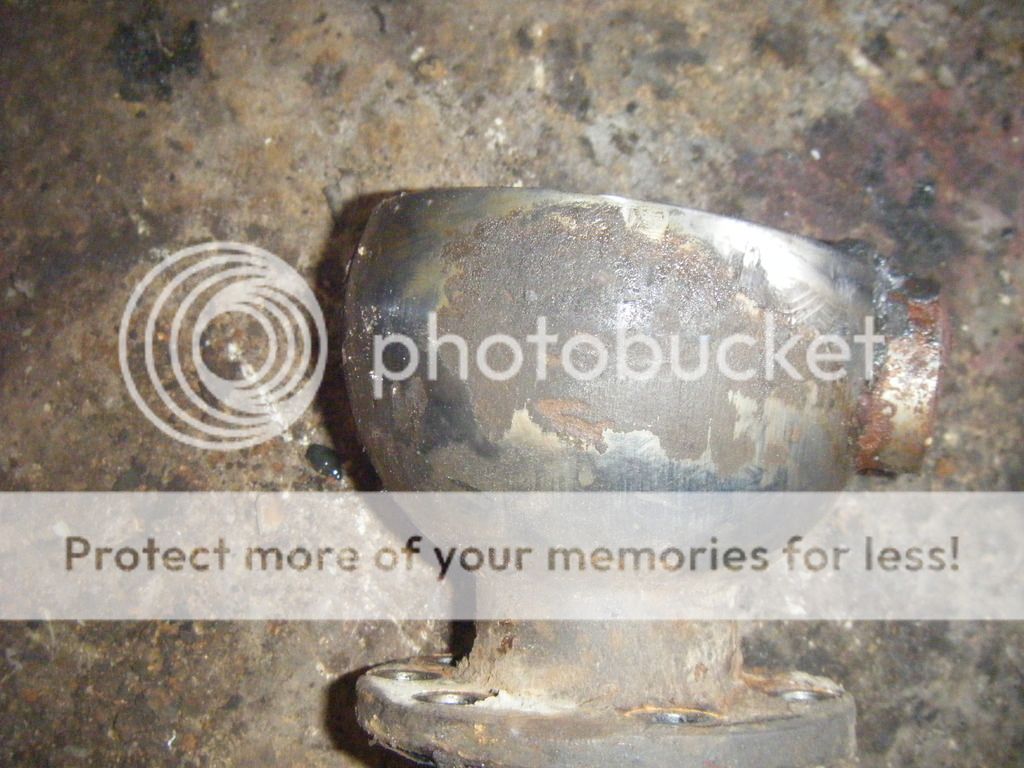

Rear with drum brakes mine is kippered

Rear with drum brakes mine is kippered

Very nice I'm after a rear axle is you have one of the to

Rear with drum brakes mine is kippered

nice one mate, gimmi a couple of weeks and ill pop up and bring the rest of your bits.

as for the fill plug, had an hour on it and its still stuck, bugger.

Nice. Nothing beats a big ass set of stilsons. So long as there is enough room to use 'em!

i've got a nice set of whale head vise grips and an impact gun for undoing shocks. but i still love my stilsons

Another great build Mate.

Hoping to start mine sometime after Christmas, never done anything like it before but your builds and others on here are a really great source of help and guidance for people like me.

I notice this one your doing has 10 spline axles, mine has too, but I have disc brakes on the rear,, been told they are off range rover classic, just had the front rebuilt do you think changing to 24 would make a lot of difference ? also never new that alloys wont fit 10 spline, nearly bought a cheap set the other week glad I didn't now.

Will have loads of questions when I finally start mine but will be watching this one for more info in the meantime.

Cheers

ay up arron, got the fill plug out earlier. made a plasticine well and let the acid do the work for me,lol.

Looking good, mate. As for the doors, I've got a thing about them! It bugs me that they are such rust traps as you say. At the time of doing mine I didn't think on about getting the frames galvanised - nugget. I got mine plastic coated instead. I've put loads of Dinitrol inside the frame, but I'm still paranoid about the rust trap thingSo, yesterday I bought a load of polythene from the garden centre and I've ordered some tubing off ebay. The plan is to put two panels of polythene in the door to guide water in to the door bottom (which is plastic coated and painted) Then, instead of the water dropping through the holes in to the frame and then out of the frame via the external drain holes, I'm going to connect the holes with pipes. So, hopefully, the water drops straight out of the bottom without spending any time in the frame. Over the top, perhaps. But, as I said, I've got a thing about it

Looking good Aaron. Are you doing the welding yourself?

Wish mine had holes in it for the door switches

Did you keep the vent mesh? Unfortunately, mine went with the old one when it was taken for part exchange. Pretty sure it was tack welded in though! I'll need to sort something or risk getting knocked out by a blackbird coming through at 50mph

At up Aaron, yup, acid from work, we've got loads lol.

Looking good Aaron. Are you doing the welding yourself?

Wish mine had holes in it for the door switches

Did you keep the vent mesh? Unfortunately, mine went with the old one when it was taken for part exchange. Pretty sure it was tack welded in though! I'll need to sort something or risk getting knocked out by a blackbird coming through at 50mph

Hi mate. Here you go, you can see a couple of tack welds in this picture. Pleased the memory hasn't completely gone! Having said that, I can't remember why I thought it significant to take a picture of me pointing at that screwIn my defence, it was over a year ago

Sorry, Aaron. Hijacking your thread here. (There used to be an apology smiley for this)

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!