Slooby

Well-Known Member

- Posts

- 355

- Location

- Tonbridge, Kent, UK

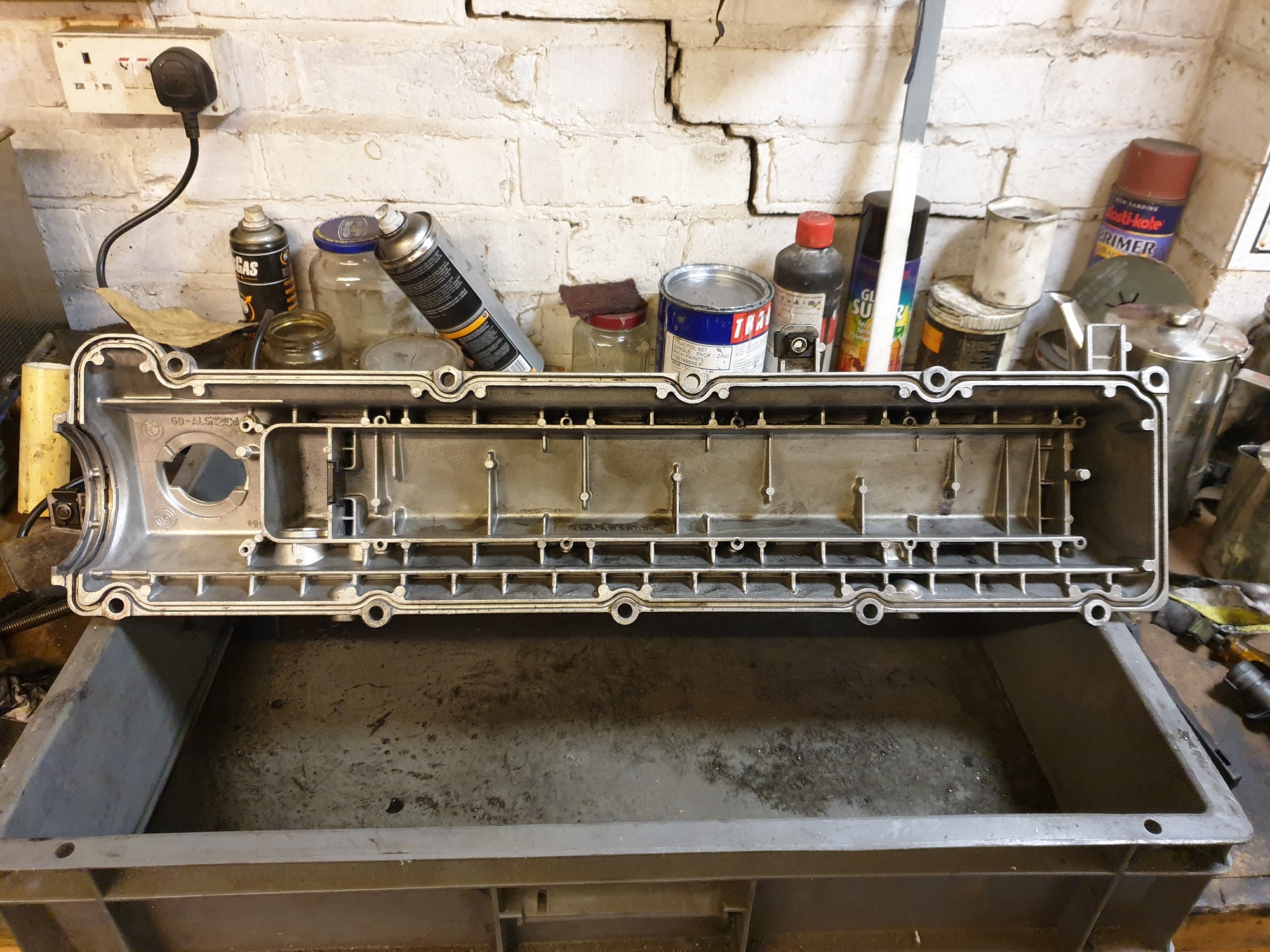

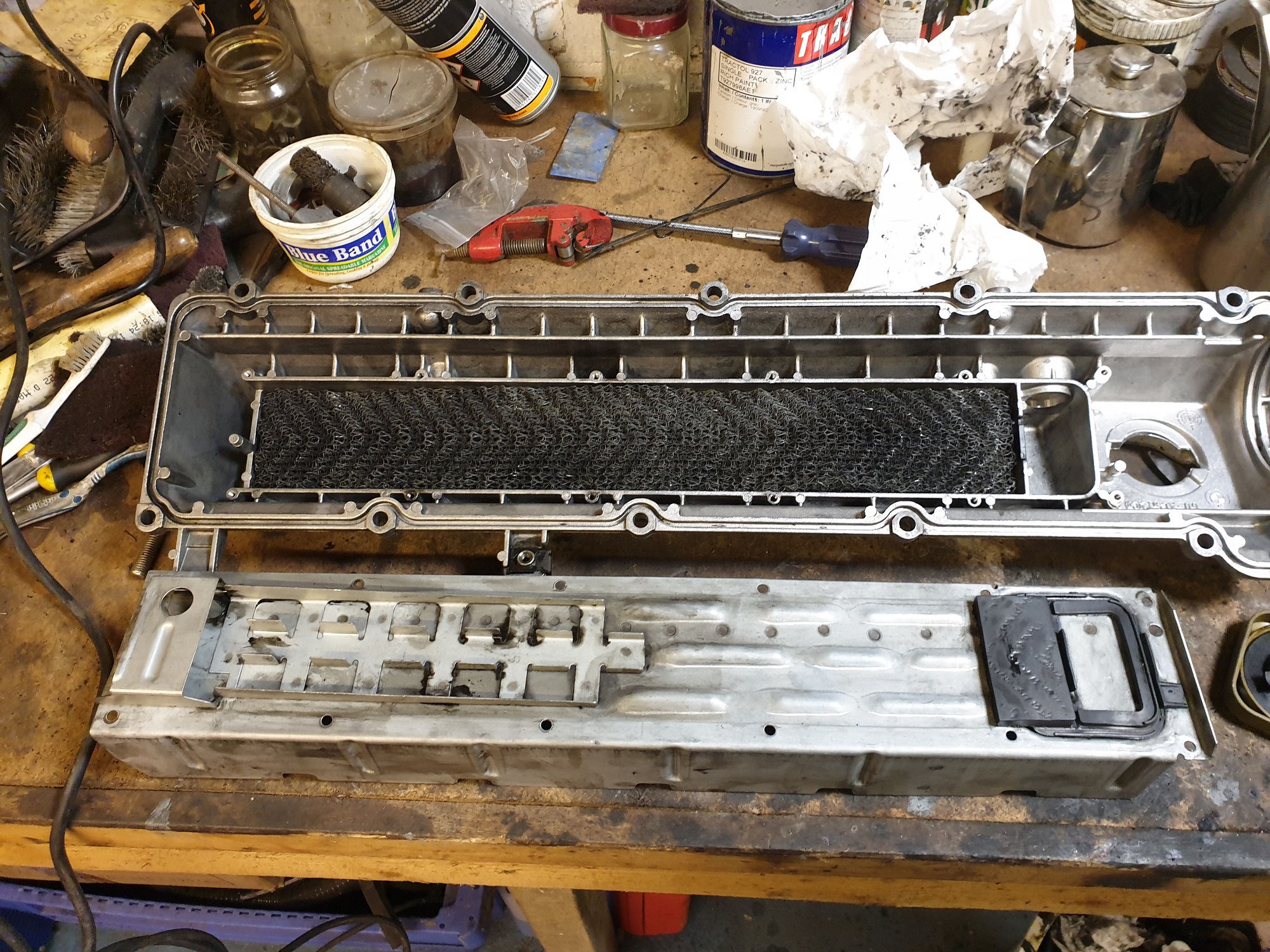

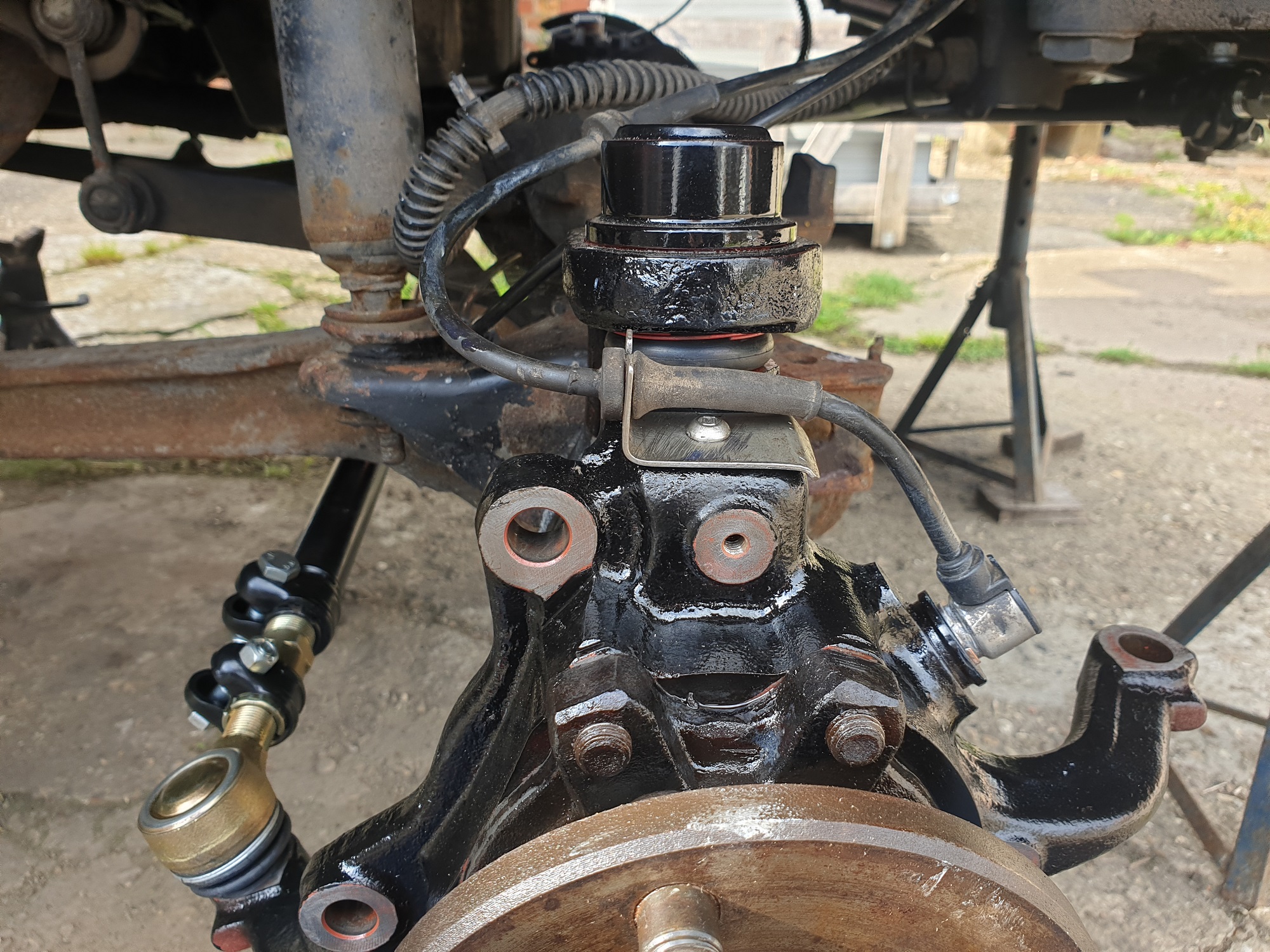

Yup, very similar games on Subaru cam covers which are lots of fun if you try to replace the seals with the engine still in the car...there's about two inches between each cover and the chassis leg...

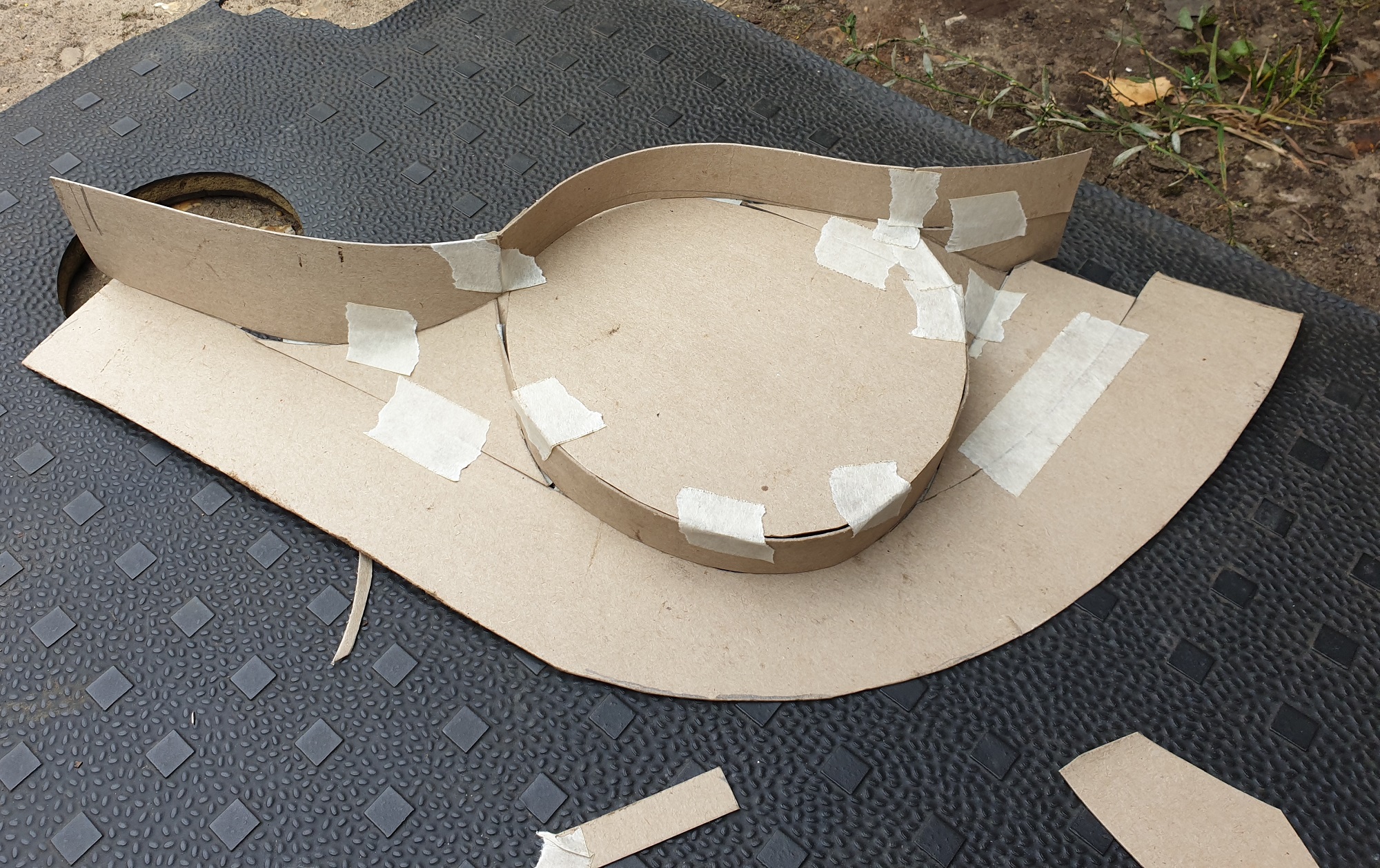

I've RTV'd the whole seal to the cover in an attempt to make things easier

I've RTV'd the whole seal to the cover in an attempt to make things easier