eightinavee

Well-Known Member

- Posts

- 3,956

- Location

- UK.

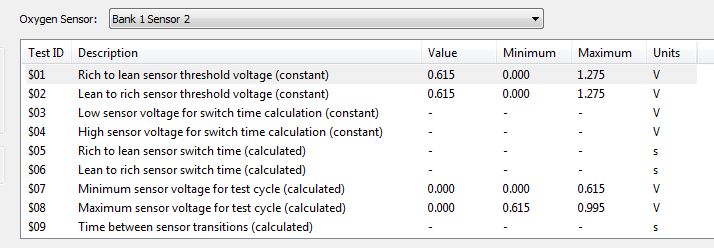

The way to sort this out is to get it on Testbook and drive it up the road whilst watching live data.From the fault it does sound very much like its running lean in the part of the fuel map where its supposed to be closed loop.Motronic seems to have a very narrow range of injector pulse width for a given rpm/throttle opening/MAF reading.If the MAF reading is too low it simply cant provide enough fuel to make power,switch the oxy sensors up to rich and get them cycling.The ecu will soon give up and stop trying to adjust the short term fuel trims and go open loop.This ends up with low power or spitting back/hesitation etc.

Whacking the throttle wide open just tells the ecu to go into the area of the fuel map where it ignores the oxy sensors and runs open loop - hence being able to drive through the fault.

I may be wrong about the low MAF reading,but someone who knows what to look for on live data displays will fix this for you.

Whacking the throttle wide open just tells the ecu to go into the area of the fuel map where it ignores the oxy sensors and runs open loop - hence being able to drive through the fault.

I may be wrong about the low MAF reading,but someone who knows what to look for on live data displays will fix this for you.