You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1965 Series 2a Station Wagon in Holland

- Thread starter Stretch

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

The electrickery is back on.

Bell end Turkish knob head had been using bell wire extension leads and blown the circuit breaker so the rest of us didn't have any power for nearly two weeks as the land lord was off elsewhere...

...so nice having mains electrickery. Got right on it with the angle grinder. I cut the bolts off the front axle's swivels. Rust had won the day - so cutting was the only way =>

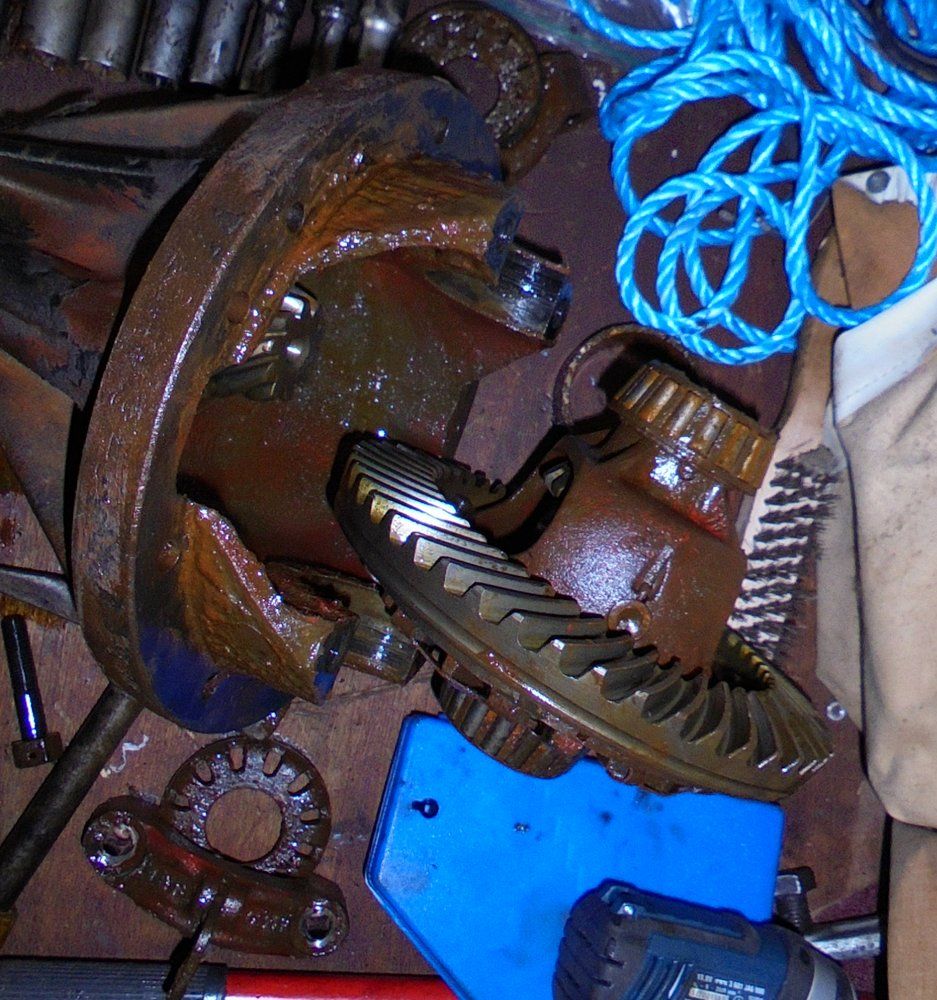

Got the front differential off too.

It looks really nice!

I'm gonna see if the engine builders place I use will chuck the axle casings in their commercial washing machine...

Bell end Turkish knob head had been using bell wire extension leads and blown the circuit breaker so the rest of us didn't have any power for nearly two weeks as the land lord was off elsewhere...

...so nice having mains electrickery. Got right on it with the angle grinder. I cut the bolts off the front axle's swivels. Rust had won the day - so cutting was the only way =>

Got the front differential off too.

It looks really nice!

I'm gonna see if the engine builders place I use will chuck the axle casings in their commercial washing machine...

Also been cocking about with molasses to see if it will be a cheaper method of de-rusting stuff =>

https://www.landyzone.co.uk/land-rover/cocking-about-with-molasses-de-rusting-will-it-work.301645/

https://www.landyzone.co.uk/land-rover/cocking-about-with-molasses-de-rusting-will-it-work.301645/

Waste of time

I found an advert for some BHB new pistons - 20 thou over sized too - got all excited. The web site where the advert was advertised sent an automised message warning me about this seller saying he might not be in Holland when I contacted the seller so the olde alarme bellse started to ring...

...turns out the old coot is in Holland but probably of German perhaps Polish descent. Lives in a very wealthy area. I now know how the old bugger got his money - pure meanness!

Advert said new.

Turned out to be used.

Turned out to be very used with broken piston rings. Lots of pitted rust damage.

Old git started to argue with me on my first in take of breath and he didn't let up.

Insisted on showing me more rusty junk - saying it wasn't his fault the stuff was rusting - that there was nothing he could do about it...

...I didn't even bother to let him into the little secret of covering exposed engine parts in grease. Lost cause.

I found an advert for some BHB new pistons - 20 thou over sized too - got all excited. The web site where the advert was advertised sent an automised message warning me about this seller saying he might not be in Holland when I contacted the seller so the olde alarme bellse started to ring...

...turns out the old coot is in Holland but probably of German perhaps Polish descent. Lives in a very wealthy area. I now know how the old bugger got his money - pure meanness!

Advert said new.

Turned out to be used.

Turned out to be very used with broken piston rings. Lots of pitted rust damage.

Old git started to argue with me on my first in take of breath and he didn't let up.

Insisted on showing me more rusty junk - saying it wasn't his fault the stuff was rusting - that there was nothing he could do about it...

...I didn't even bother to let him into the little secret of covering exposed engine parts in grease. Lost cause.

Yesterday I did a bit.

Got the front differential a bit further along.

I think I've ordered the bearings from 'addocks - I'll have to check my order though. Got to find my bearing removal puller kit first though.

(Being organised is everything!)

Got the front differential a bit further along.

I think I've ordered the bearings from 'addocks - I'll have to check my order though. Got to find my bearing removal puller kit first though.

(Being organised is everything!)

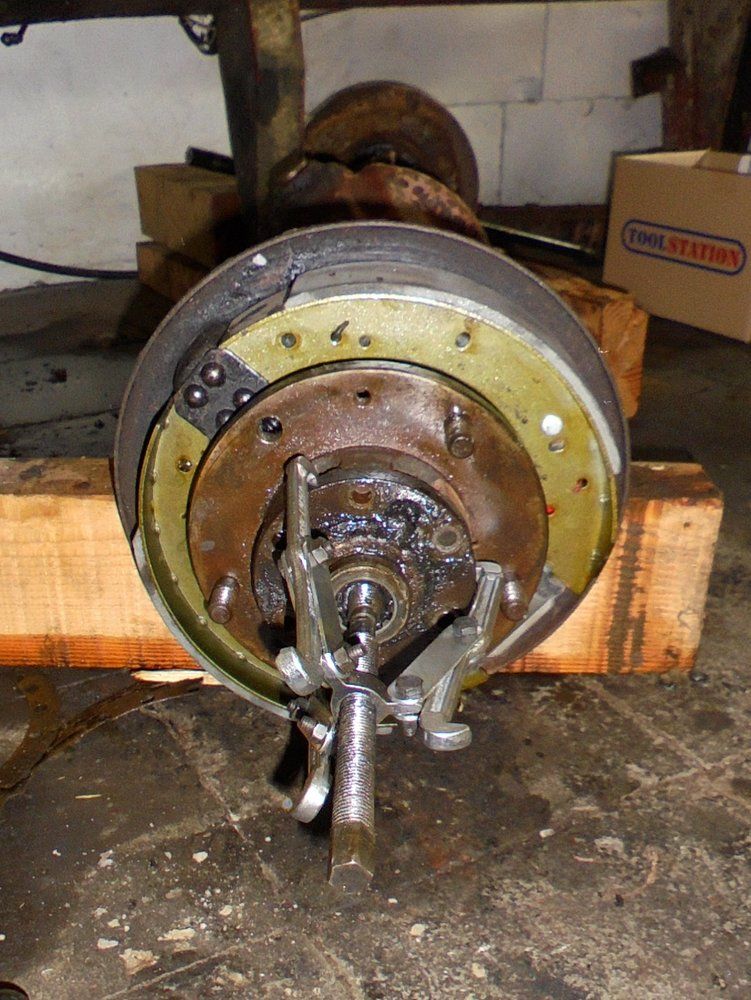

Rear differential is in much better condition

I understand that using a three legged puller to remove the driving plate bit isn't always necessary!

Special tool for the axle bearings is a must - much better than the hammer and chisel method used by the "expert mechanic" shown previously in the thread - tosser...

Oil is dirty - but minimal rust - which is good! =>

Locking wire on the bolt heads on the inside of the axle housing has gone west...

I understand that using a three legged puller to remove the driving plate bit isn't always necessary!

Special tool for the axle bearings is a must - much better than the hammer and chisel method used by the "expert mechanic" shown previously in the thread - tosser...

Oil is dirty - but minimal rust - which is good! =>

Locking wire on the bolt heads on the inside of the axle housing has gone west...

Front propshaft is getting new universal joints. One end was seized. Needle bearings all rusted out.

After removing the circlips I pressed the caps out with a hydraulic press by moving the UJ cross piece within the ends of the yokes so the caps came out.

On the back end of the propshaft I was lucky with the circlips. The front end ones were rusted and so broke off in the yokes. That took a bit of jiggling by pressing the caps inwards a bit so I could pick out the broken circlip pieces.

The picture above shows (I think!) how the outer side of the yoke is being supported by some sockets and that I'm using a larger socket on top that is big enough inside the socket for the cap of the UJ to pass within

Picture above shows the needle roller bearings now that a cap has been removed.

Sometimes it was necessary to push the caps with collapsed needle roller bearings inside to get the cap on the other side out (if you see what I mean? - Probably not - try it yourself and you might see what I mean!)

Once you've wiggled the UJ cross piece out of the way you just need to push out the last cap that is stuck in the yoke.

I didn't really need to resort to this =>

...but as I'm replacing everything...

After removing the circlips I pressed the caps out with a hydraulic press by moving the UJ cross piece within the ends of the yokes so the caps came out.

On the back end of the propshaft I was lucky with the circlips. The front end ones were rusted and so broke off in the yokes. That took a bit of jiggling by pressing the caps inwards a bit so I could pick out the broken circlip pieces.

The picture above shows (I think!) how the outer side of the yoke is being supported by some sockets and that I'm using a larger socket on top that is big enough inside the socket for the cap of the UJ to pass within

Picture above shows the needle roller bearings now that a cap has been removed.

Sometimes it was necessary to push the caps with collapsed needle roller bearings inside to get the cap on the other side out (if you see what I mean? - Probably not - try it yourself and you might see what I mean!)

Once you've wiggled the UJ cross piece out of the way you just need to push out the last cap that is stuck in the yoke.

I didn't really need to resort to this =>

...but as I'm replacing everything...

More on the front propshaft.

Removal of the jubilee clips on the rubber bellows was hard! Nightmare - stuck - needed loads of penetrating oil and a half inch drive flat head screw driver with a grolly bar to get them off.

I really wanted to save the rubber bellows because I bet the new versions rot and fall off the propshaft after 30 minutes - whereas this original one just needs a clean and some aerospace303 to get it back into shape.

Eventually I got to this stage =>

Once cleaned I noticed a bit of play in the splines. Green book says you can have up to 1mm rotational play in the splines - I haven't bothered to set up a DTI on it just yet.

I'm gonna gamble on getting a new front yoke section. The 'addocks sell them for about 15 quid which seems like a reasonable gamble to take to me as the rear section splines look brand new.

So I'm just gonna derust the rear section (also known as the big bit)

Using the cheapo drill wire brush junk from silverline so I don't gouge out big lumps by accident =>

Rustyco treatment after a bit of degreasing with brake cleaner =>

An hour later after a rub down with some wire wool =>

It is now back under a new layer of Rustyco gel to clean up the last bits before I start with a thin layer of Ferpox undercoat.

Removal of the jubilee clips on the rubber bellows was hard! Nightmare - stuck - needed loads of penetrating oil and a half inch drive flat head screw driver with a grolly bar to get them off.

I really wanted to save the rubber bellows because I bet the new versions rot and fall off the propshaft after 30 minutes - whereas this original one just needs a clean and some aerospace303 to get it back into shape.

Eventually I got to this stage =>

Once cleaned I noticed a bit of play in the splines. Green book says you can have up to 1mm rotational play in the splines - I haven't bothered to set up a DTI on it just yet.

I'm gonna gamble on getting a new front yoke section. The 'addocks sell them for about 15 quid which seems like a reasonable gamble to take to me as the rear section splines look brand new.

So I'm just gonna derust the rear section (also known as the big bit)

Using the cheapo drill wire brush junk from silverline so I don't gouge out big lumps by accident =>

Rustyco treatment after a bit of degreasing with brake cleaner =>

An hour later after a rub down with some wire wool =>

It is now back under a new layer of Rustyco gel to clean up the last bits before I start with a thin layer of Ferpox undercoat.

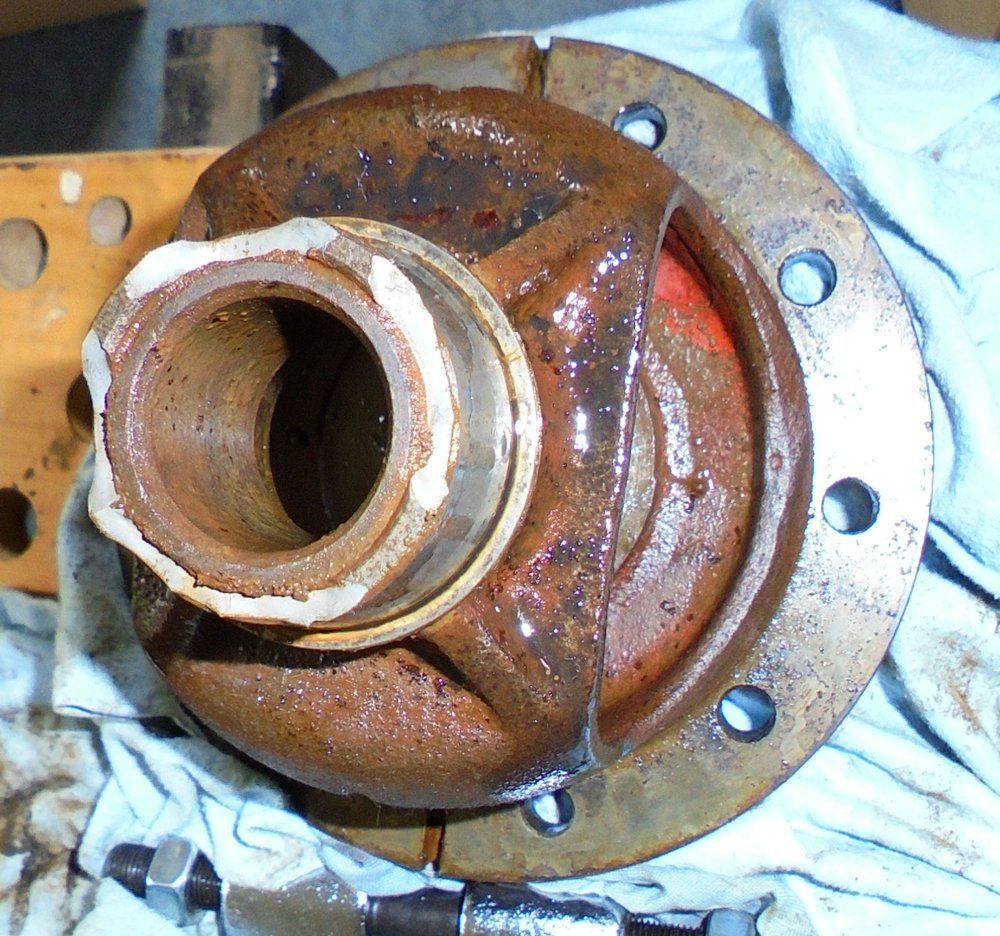

Bad news on the front differential again =>

Axial bearing came off the crown wheel side alright...

...unfortunately the rust has gotten to the other side...

...I can try and cut the inner part of the bear away from the housing but I have a feeling there will probably be corrosion damage underneath...

...I'm hunting for a replacement differential to see if that will end up being a more economical solution

Axial bearing came off the crown wheel side alright...

...unfortunately the rust has gotten to the other side...

...I can try and cut the inner part of the bear away from the housing but I have a feeling there will probably be corrosion damage underneath...

...I'm hunting for a replacement differential to see if that will end up being a more economical solution

doodle bug

Well-Known Member

- Posts

- 4,757

- Location

- the dog house

Try ...paginamarkt.nl theres usualy someone on there with stuff or try vandamrhenen.nl he,s got loads of diffsBad news on the front differential again =>

Axial bearing came off the crown wheel side alright...

View attachment 103058

...unfortunately the rust has gotten to the other side...

View attachment 103059

...I can try and cut the inner part of the bear away from the housing but I have a feeling there will probably be corrosion damage underneath...

View attachment 103060

...I'm hunting for a replacement differential to see if that will end up being a more economical solution

Thanks I'll check those places outTry ...paginamarkt.nl theres usualy someone on there with stuff or try vandamrhenen.nl he,s got loads of diffs

doodle bug

Well-Known Member

- Posts

- 4,757

- Location

- the dog house

there is another guy in rotterdam called ron bollenboom but i cant remember his address!!! he,s always selling bits on paginamarkt.....if you get real stuck PM meThanks I'll check those places out

Thanks I've heard of him too.there is another guy in rotterdam called ron bollenboom but i cant remember his address!!! he,s always selling bits on paginamarkt.....if you get real stuck PM me

I think I've just bought a second hand one from a chap called Arend who does Land Rover and jeep parts. He's also in the Randstad area of Holland so I'm trying to get it sent by post. Bloody long drive for just a differential.

Dan_Trials

Well-Known Member

- Posts

- 2,546

Ah good you are doing stuff! Looks like it's moving in the right direction overall.

At the weekend I did a Land Rover thing, I took the mostly fallen off door completely off the Discovery

At the weekend I did a Land Rover thing, I took the mostly fallen off door completely off the Discovery

Thanks Dan,Ah good you are doing stuff! Looks like it's moving in the right direction overall.

At the weekend I did a Land Rover thing, I took the mostly fallen off door completely off the Discovery

Are mostly falling off doors normal on Discovery's? I've heard bad bad - oh so bad - things about Freelanders but thought the Discovery's were a bit better...

Similar threads

- Replies

- 6

- Views

- 1K