You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steve's unexpected Series 3 rebuild.

- Thread starter LincolnSteve

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

I keep trying to do a bit where I can. There always seems to be something higher priority that needs doing first though. Not worried really, it will get done. I doubt the heater mod will be wildly effective but it can't hurt.Nice to see more progress

Like the heater mod too - let's face it, it can hardly be worse...

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Normally I don't post stuff on here until it's about finalised but at the moment nothing is getting finalised. I start something and then something else crops up. I'm just going to show you what's been happening and then later the story will complete itself.

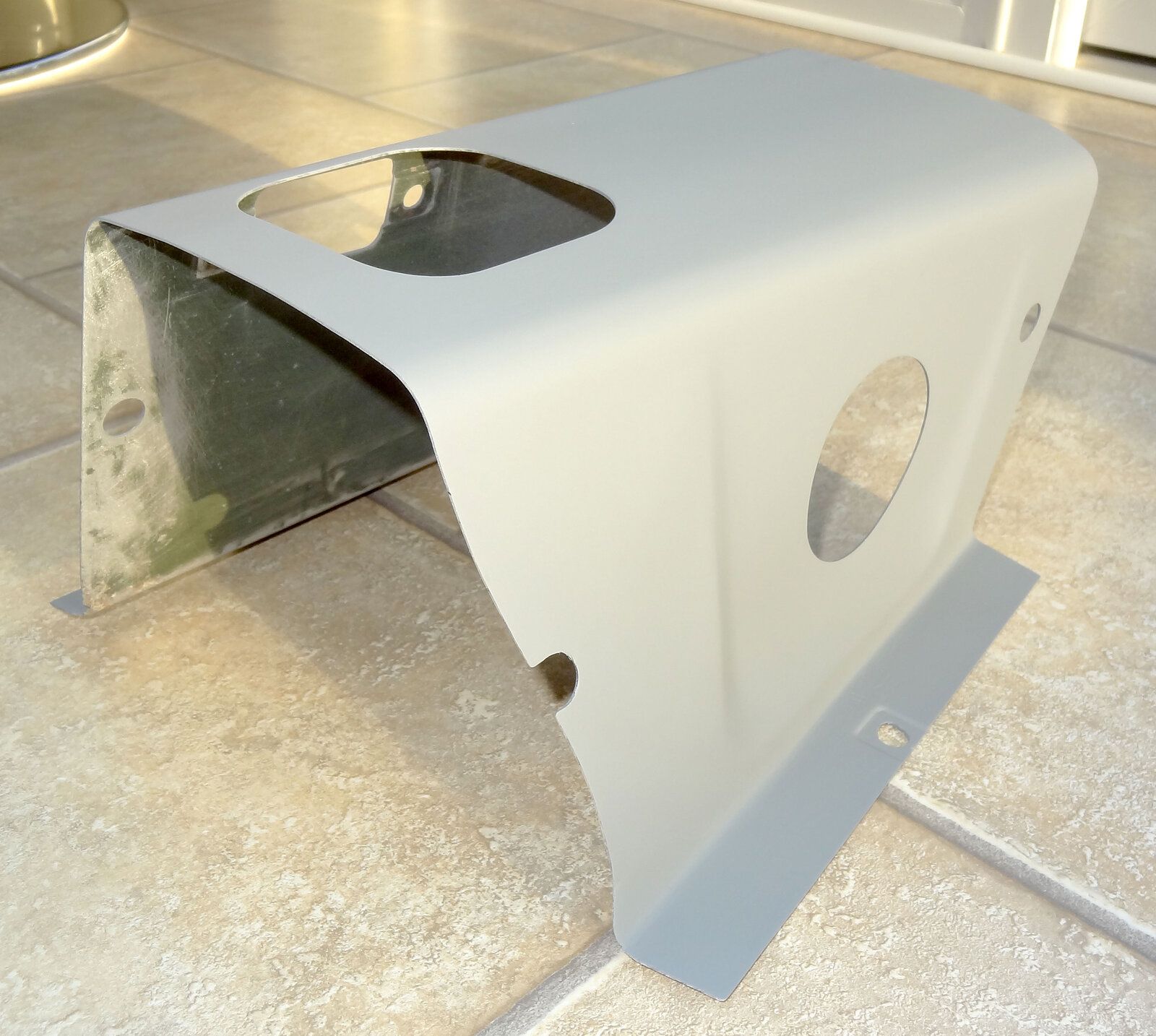

I've got a few bits of bodywork ready.

This now means i've got to decide how to paint the thing. I've got new doors and rear quarter panels just in their black primer so it's got to be done. Can't face spraying. I've not got enough room, no experience, no spray gun, my compressor is probably not up to it and I certainly can't afford to pay someone else to do it. It's never going to be a top resto anyway so i'm going for rolling and tipping with enamel paints. I've had a very quick practice and the results seem ok so far. Probably regret it later but there we are.

This now means i've got to decide how to paint the thing. I've got new doors and rear quarter panels just in their black primer so it's got to be done. Can't face spraying. I've not got enough room, no experience, no spray gun, my compressor is probably not up to it and I certainly can't afford to pay someone else to do it. It's never going to be a top resto anyway so i'm going for rolling and tipping with enamel paints. I've had a very quick practice and the results seem ok so far. Probably regret it later but there we are.

I've got a few bits of bodywork ready.

steve2286w

Well-Known Member

- Posts

- 5,178

- Location

- monkeyangerland

How do you get the parts so paint free and clean and looking

I did my gearbox tunnel cover using HMG synthetic enamel and with just a touch of white spirit added gave a surprising good shiny finish not there if used unthinned using brush and roller

I did my gearbox tunnel cover using HMG synthetic enamel and with just a touch of white spirit added gave a surprising good shiny finish not there if used unthinned using brush and roller

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

A mixture of ways. Paint stripper for some bits. Modern paint strippers aren't half as good as Nitromors used to be years ago. I did use a wire cup brush on the angle grinder but you have to go really steady with that as it can gouge the surface easily. Then just hand sanding. It helps that i'm an OCD lunatic who just overdoes everything. I'm sure that's the paint i've got. So you sprayed yours?

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

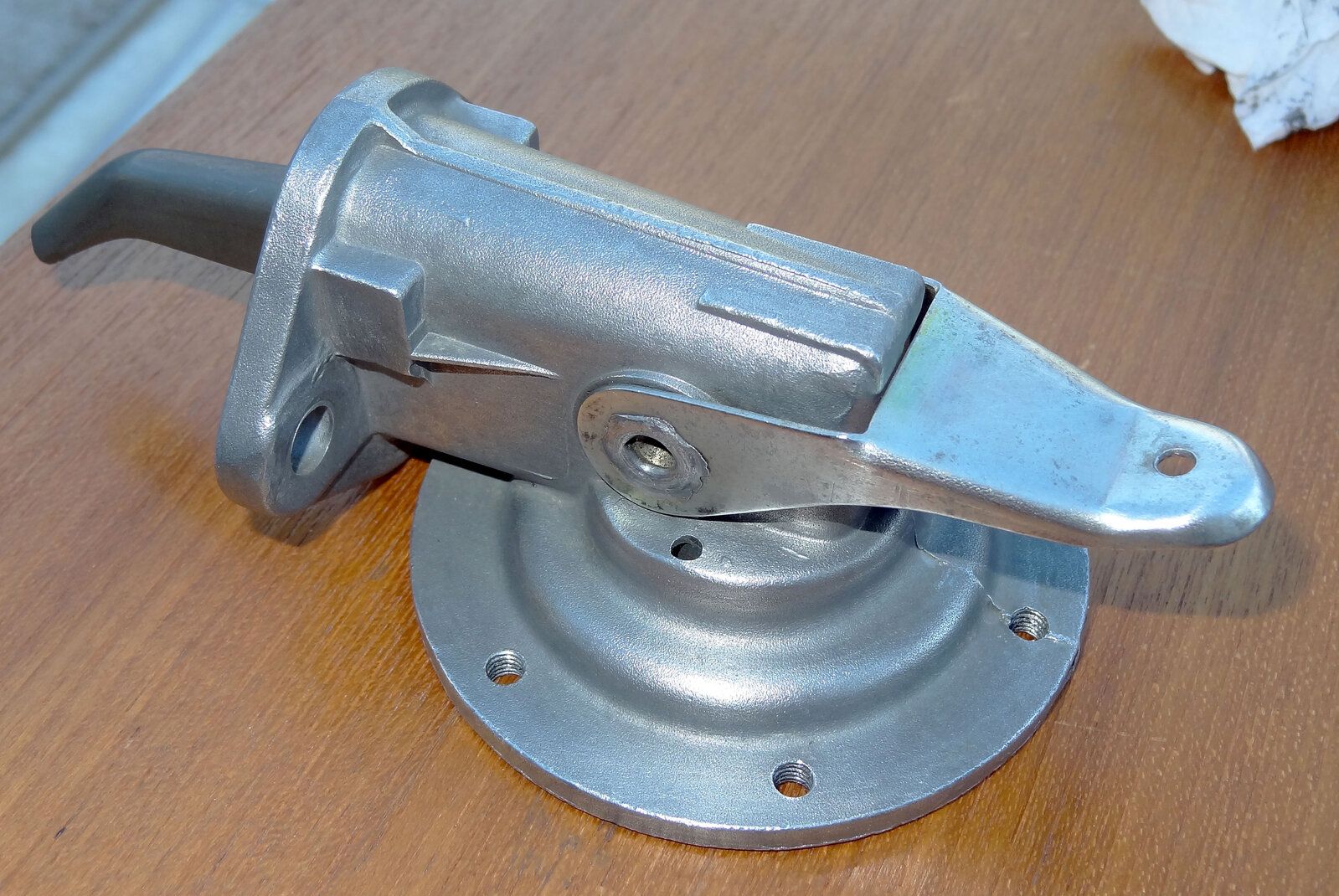

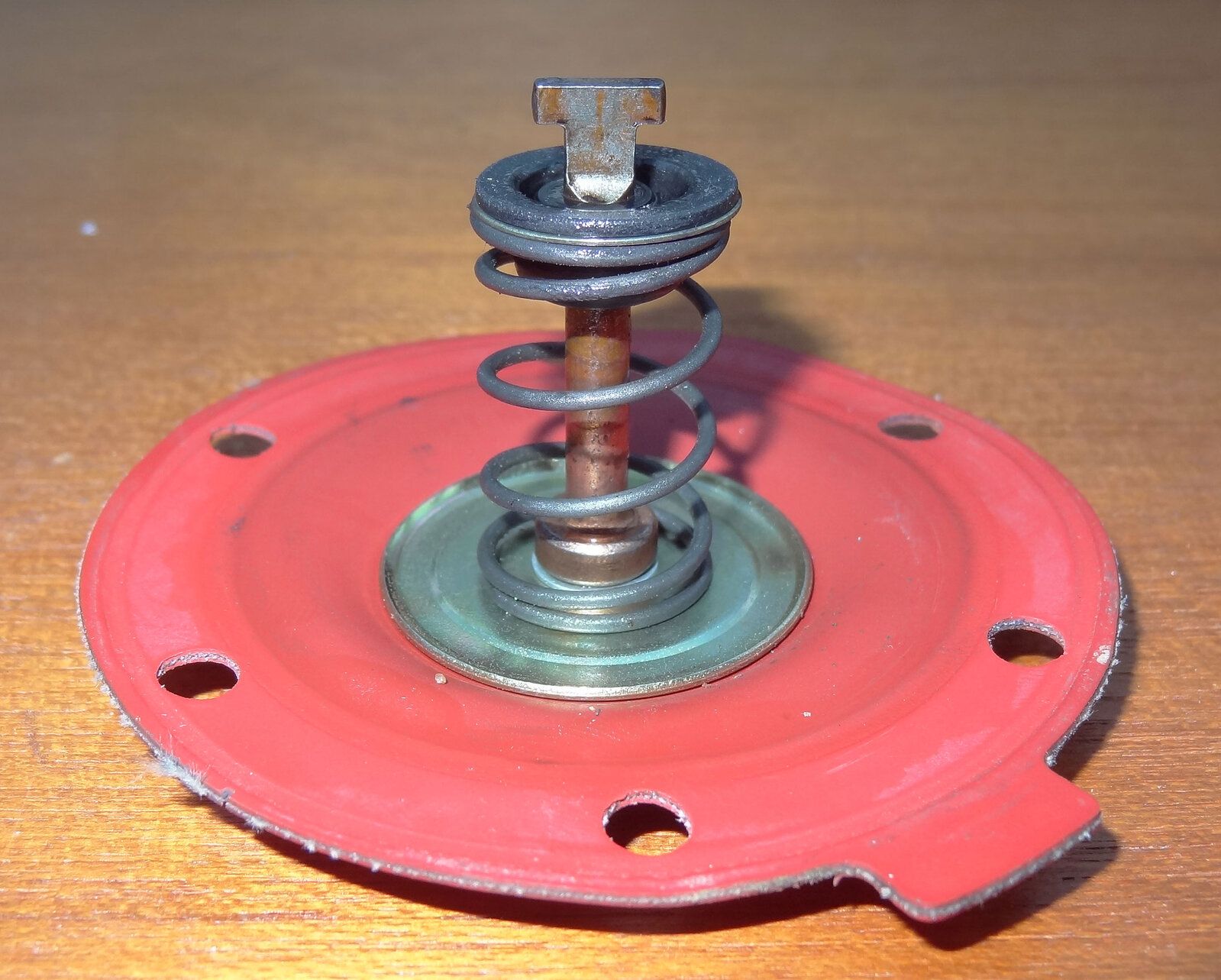

There was some confusion with the fuel pump.

Got it taken to pieces and cleaned up.

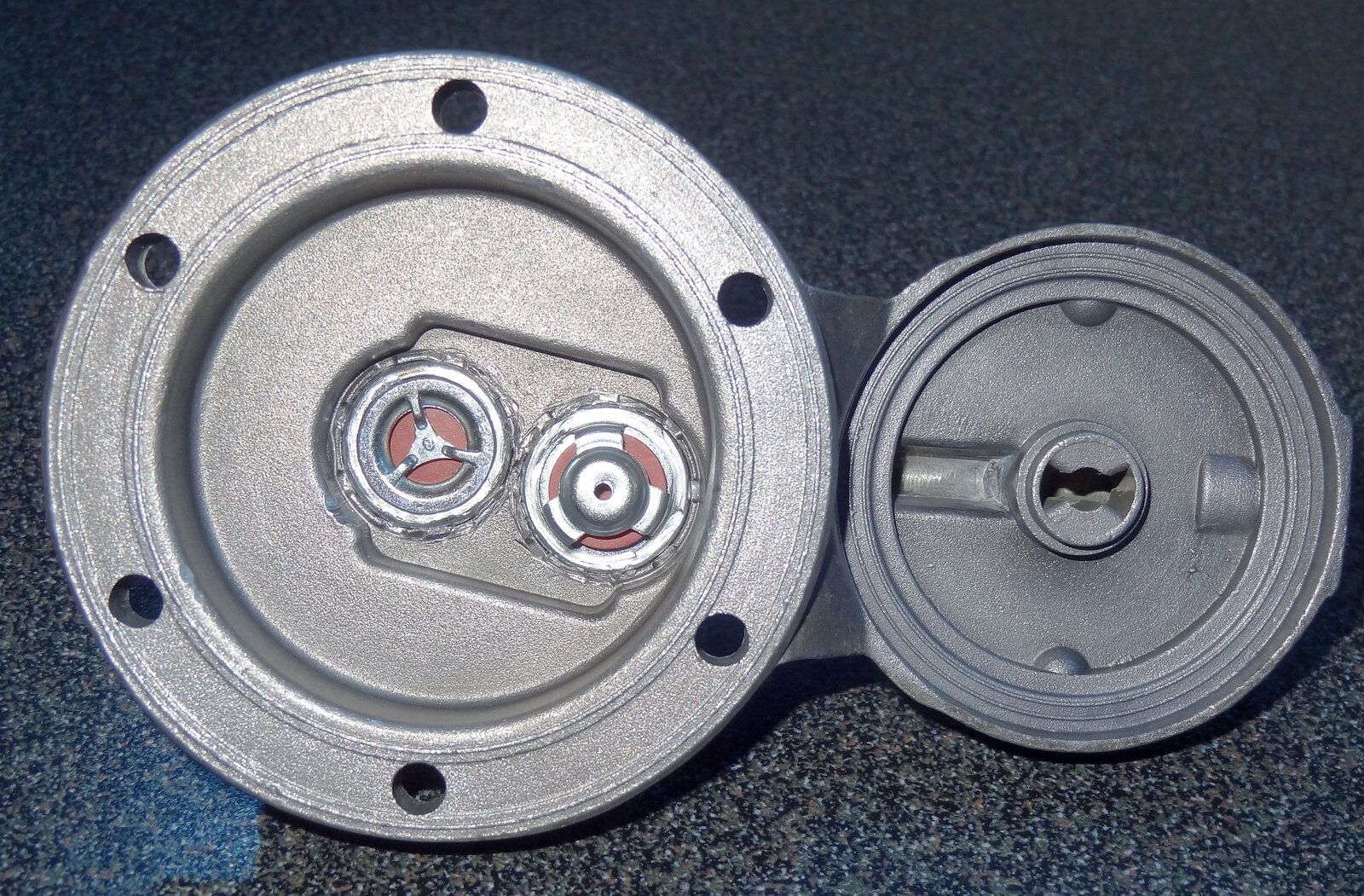

Replaced the little one directional valves.

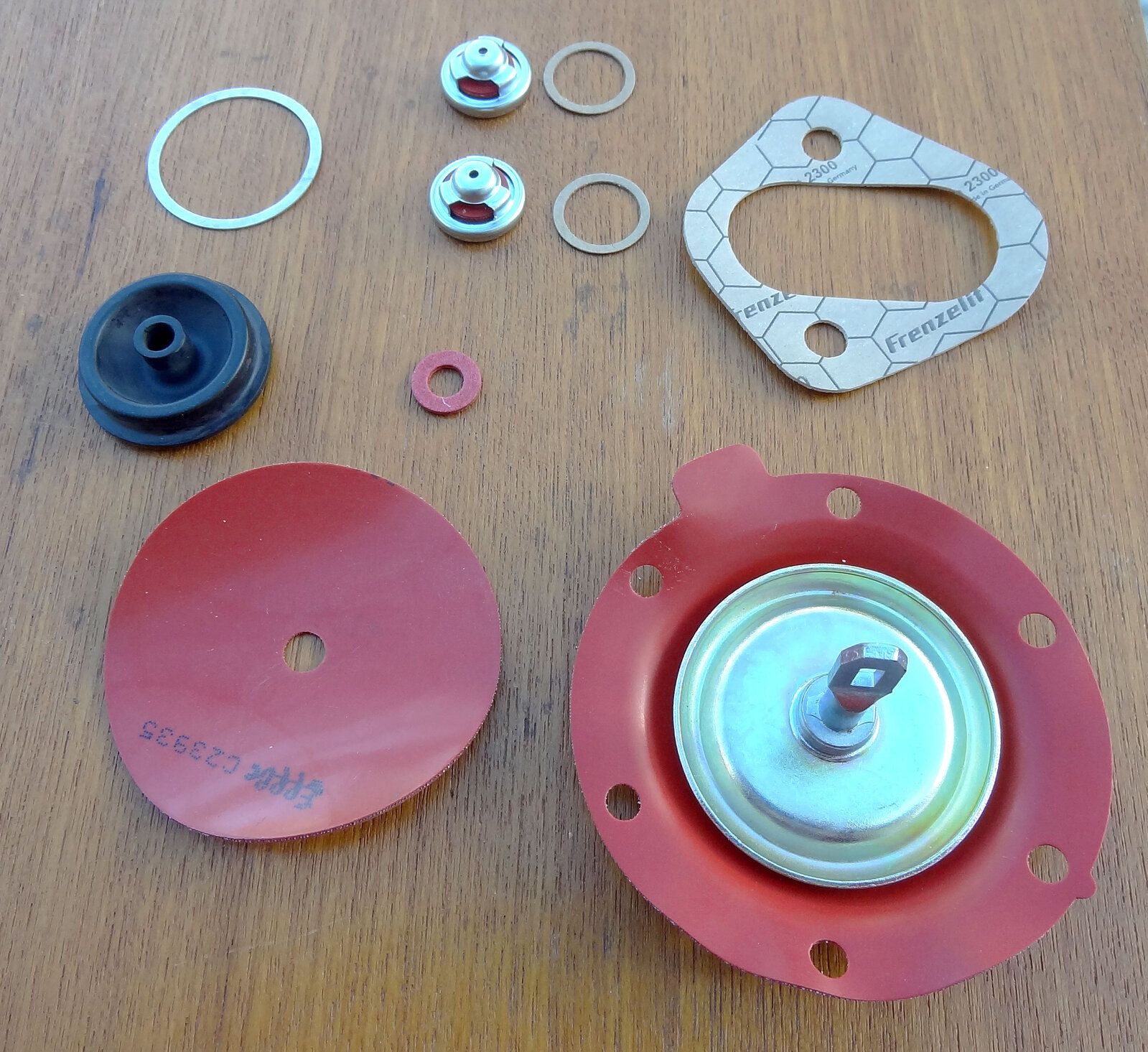

The refurb kit seemed good but then I realised that them rubber diaphragm was different to mine.

There's the new one, below is my old one.

Nobody seems to sell one like mine. I asked around and put a question on the zone but got no joy so decided to have a look at how bad the old one was.

Not ideal but not disastrous. This is happening more and more at the moment. Refurbing stuff and either can't get or can't afford the parts to make it perfect so just cleaning it all up and putting it back together. I thought i'd better test this though.

Pumps like a good 'un. I could replace the whole thing I suppose but you hear stories about the new ones being rubbish so i'll go with this for as long as it keeps going then replace later. That's another thing i'm finding. I go to replace parts and the quality of the new bit is nothing like the quality of the old bit. Then the question is do you go with part worn better quality or new lower quality?

Pumps like a good 'un. I could replace the whole thing I suppose but you hear stories about the new ones being rubbish so i'll go with this for as long as it keeps going then replace later. That's another thing i'm finding. I go to replace parts and the quality of the new bit is nothing like the quality of the old bit. Then the question is do you go with part worn better quality or new lower quality?

Got it taken to pieces and cleaned up.

Replaced the little one directional valves.

The refurb kit seemed good but then I realised that them rubber diaphragm was different to mine.

There's the new one, below is my old one.

Nobody seems to sell one like mine. I asked around and put a question on the zone but got no joy so decided to have a look at how bad the old one was.

Not ideal but not disastrous. This is happening more and more at the moment. Refurbing stuff and either can't get or can't afford the parts to make it perfect so just cleaning it all up and putting it back together. I thought i'd better test this though.

Turboman

Mab An Gov

- Posts

- 60,151

- Location

- Lathrowda, Kernow

It is pretty hard to say from pictures, but if the holes in the diaphragm are right, and you can get the top washer and spring to stay on, I think the new one will work.There was some confusion with the fuel pump.

View attachment 227854

Got it taken to pieces and cleaned up.

View attachment 227855

View attachment 227856

View attachment 227857

Replaced the little one directional valves.

View attachment 227859

View attachment 227860

The refurb kit seemed good but then I realised that them rubber diaphragm was different to mine.

View attachment 227863

There's the new one, below is my old one.

View attachment 227868

Nobody seems to sell one like mine. I asked around and put a question on the zone but got no joy so decided to have a look at how bad the old one was.

View attachment 227874

Not ideal but not disastrous. This is happening more and more at the moment. Refurbing stuff and either can't get or can't afford the parts to make it perfect so just cleaning it all up and putting it back together. I thought i'd better test this though.

View attachment 227875 Pumps like a good 'un. I could replace the whole thing I suppose but you hear stories about the new ones being rubbish so i'll go with this for as long as it keeps going then replace later. That's another thing i'm finding. I go to replace parts and the quality of the new bit is nothing like the quality of the old bit. Then the question is do you go with part worn better quality or new lower quality?

None of these kits are usually exactly the same, they make little adjustments and improvements over time.

steve2286w

Well-Known Member

- Posts

- 5,178

- Location

- monkeyangerland

No just brush and roller but thinned down it flows better leaving no brush marksI'm sure that's the paint i've got. So you sprayed yours?

I’ll be doing the rear panels later in year when weather warms up

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

That's really good to hear. I'm partly looking forward to painting but I can't imagine my first efforts are going to be great. It does give me the hump if I make a bad job of stuff as well so I might have quite a grumpy time of it. I'm hoping that I can get my technique sorted while doing the primer so i'm better on the top coat.No just brush and roller but thinned down it flows better leaving no brush marks

I’ll be doing the rear panels later in year when weather warms up

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

I've kept all the bits so when the other finally gives up I can have another go. Thanks for the info.It is pretty hard to say from pictures, but if the holes in the diaphragm are right, and you can get the top washer and spring to stay on, I think the new one will work.

None of these kits are usually exactly the same, they make little adjustments and improvements over time.

Turboman

Mab An Gov

- Posts

- 60,151

- Location

- Lathrowda, Kernow

You have done better than I usually do. I usually leave the little valves in place, and just change the diaphragm and spring.I've kept all the bits so when the other finally gives up I can have another go. Thanks for the info.

Not had any problems doing that.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

I didn't quite realise what I was getting into with those little valves. There's only so much metal round the edge of the hole so I don't suppose you could replace them many times before there would be nothing left to peen over. Hopefully they will be good for a long long time now.You have done better than I usually do. I usually leave the little valves in place, and just change the diaphragm and spring.

Not had any problems doing that.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

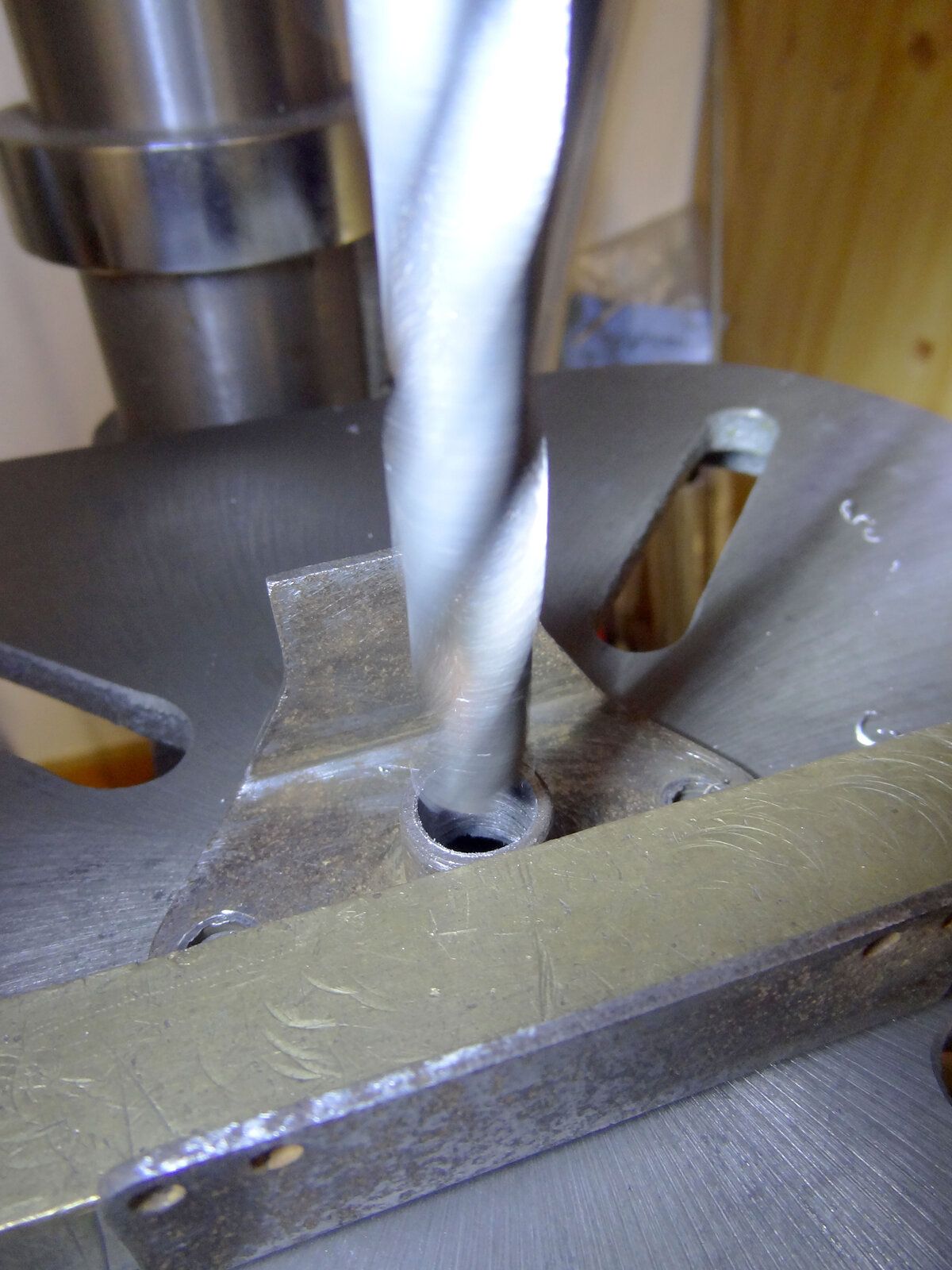

The throttle pedal linkage is long and complicated. On the very few occasions I drove it there was a huge amount of play in the pedal. It made it hard to pull away smoothly and spoiled the experience a bit. I want all the controls and bits you touch to feel good when it's finished so i'm going to do my best on them.

The shaft is bound to wear because there is no sort of bearing to stop it happening. You can get new shafts but that's no good when the brackets are worn as well so I got a piece of bar that is slightly thicker than the original and adjusted the brackets.

Action shots and everything! That was simple to enlarge the hole. Still no bearing but it took 40 years to wear the old one out so it will do for me.

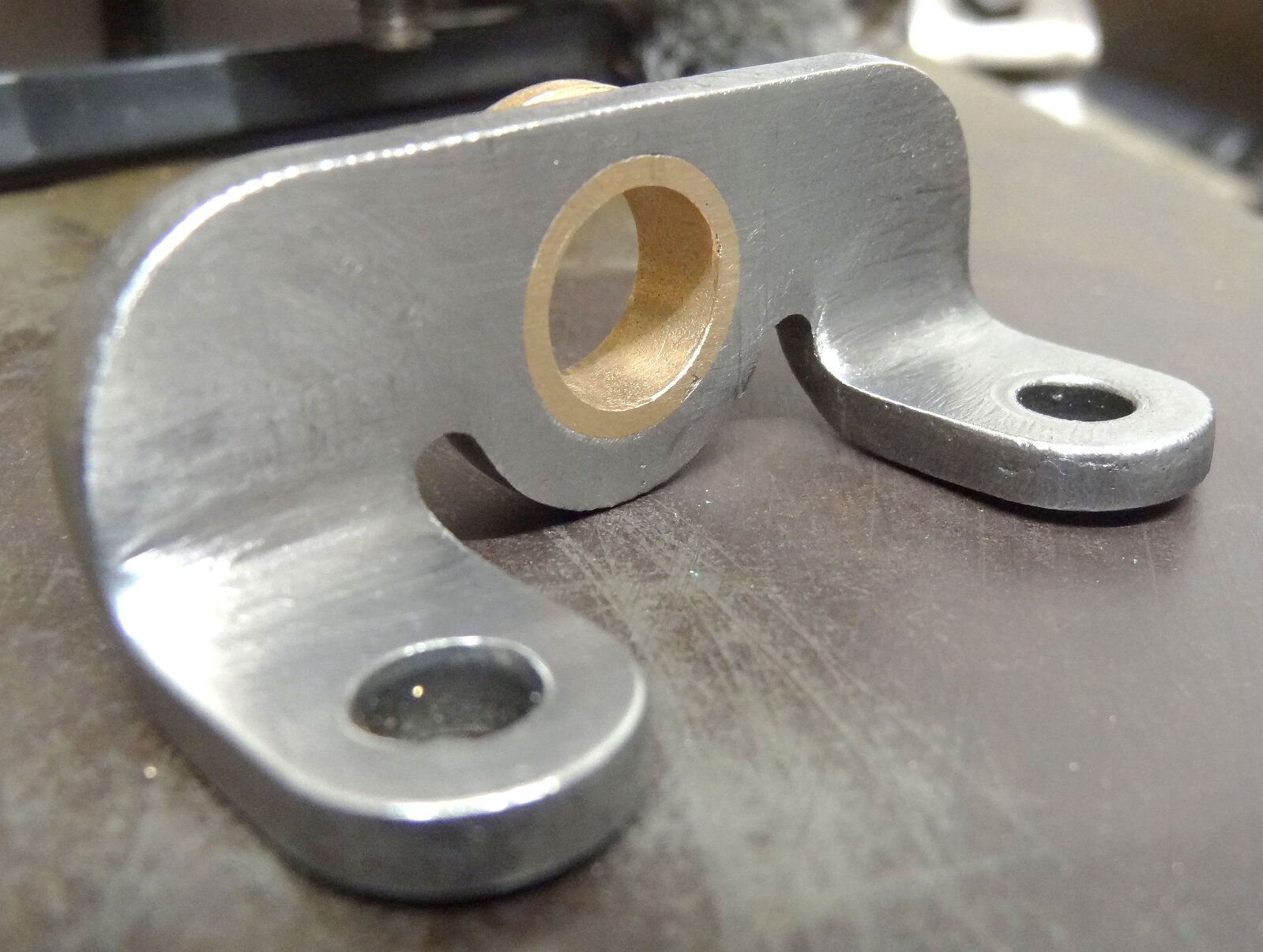

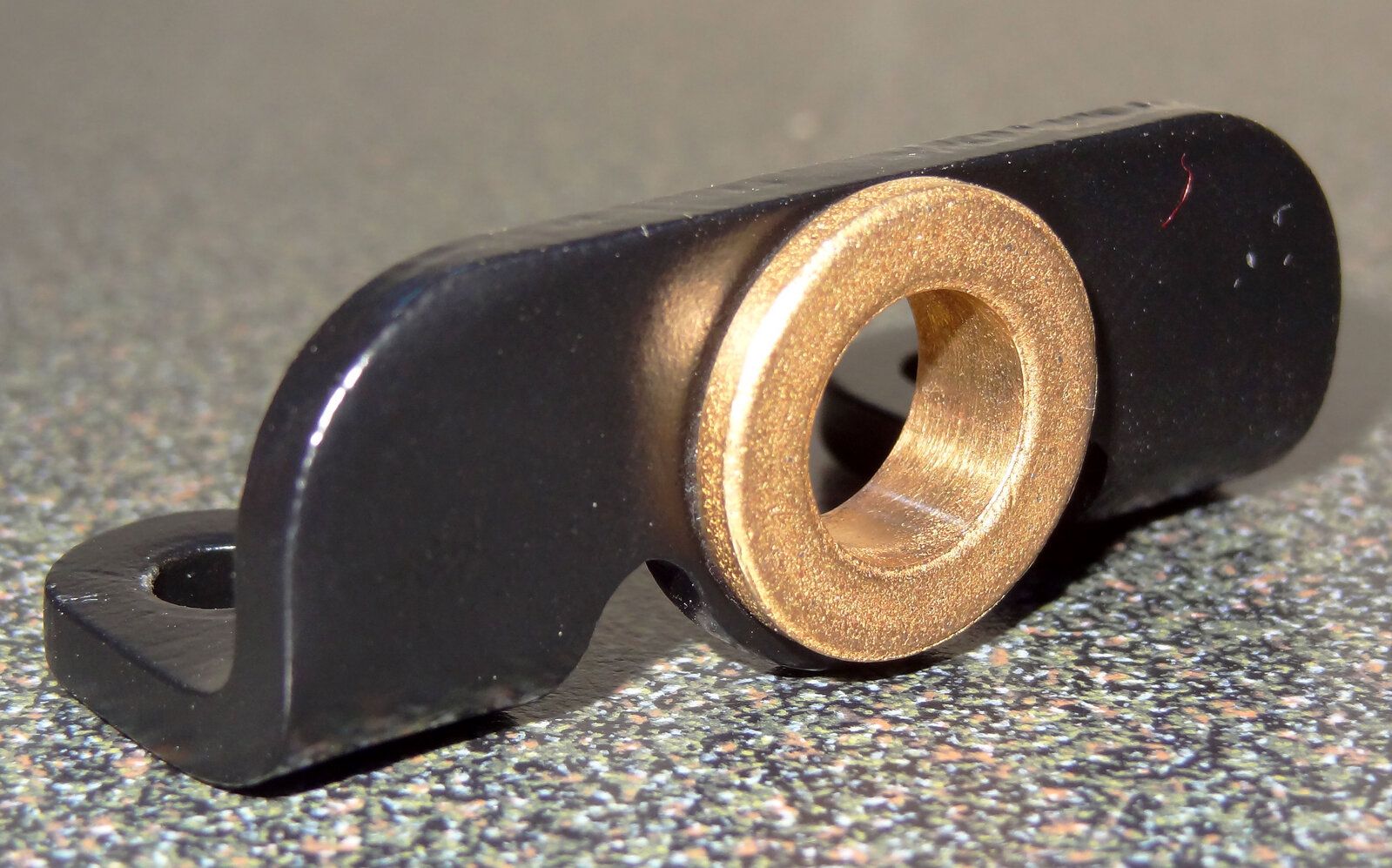

The other bracket had a bit more meat on it so made it possible to fit a bush. I'd never heard of top hat bushes until I was searching on ebay and got all excited.

I got the bracket all cleaned up, enlarged the hole and encouraged the bush in. Cut off the excess and filed it smooth. With a bit of paint on it looks like it ought to be there. Hopefully it will be a nice little upgrade.

The shaft is bound to wear because there is no sort of bearing to stop it happening. You can get new shafts but that's no good when the brackets are worn as well so I got a piece of bar that is slightly thicker than the original and adjusted the brackets.

Action shots and everything! That was simple to enlarge the hole. Still no bearing but it took 40 years to wear the old one out so it will do for me.

The other bracket had a bit more meat on it so made it possible to fit a bush. I'd never heard of top hat bushes until I was searching on ebay and got all excited.

I got the bracket all cleaned up, enlarged the hole and encouraged the bush in. Cut off the excess and filed it smooth. With a bit of paint on it looks like it ought to be there. Hopefully it will be a nice little upgrade.

auld duffer

Well-Known Member

- Posts

- 577

- Location

- scotland

Nice solution with the bushes in the throttle pedal brackets .

I made a big mistake in tossing the original fuel pump in the bin during one of my many clear up sessions . I fitted a new replacement but its not a patch on the quality of the original . Maybee the original was just over engineered , time will tell . One thig with the original would be the compatibility with ethanol fuels . I haven't had much luck with electric pumps, they seem to stick and burn out pretty quick . I eventually went back to mechanical on my old VW . So far its been fine , but I have a feeling I've just jinxed that ..

Looking forward to more updates on your rebuild .

I made a big mistake in tossing the original fuel pump in the bin during one of my many clear up sessions . I fitted a new replacement but its not a patch on the quality of the original . Maybee the original was just over engineered , time will tell . One thig with the original would be the compatibility with ethanol fuels . I haven't had much luck with electric pumps, they seem to stick and burn out pretty quick . I eventually went back to mechanical on my old VW . So far its been fine , but I have a feeling I've just jinxed that ..

Looking forward to more updates on your rebuild .

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

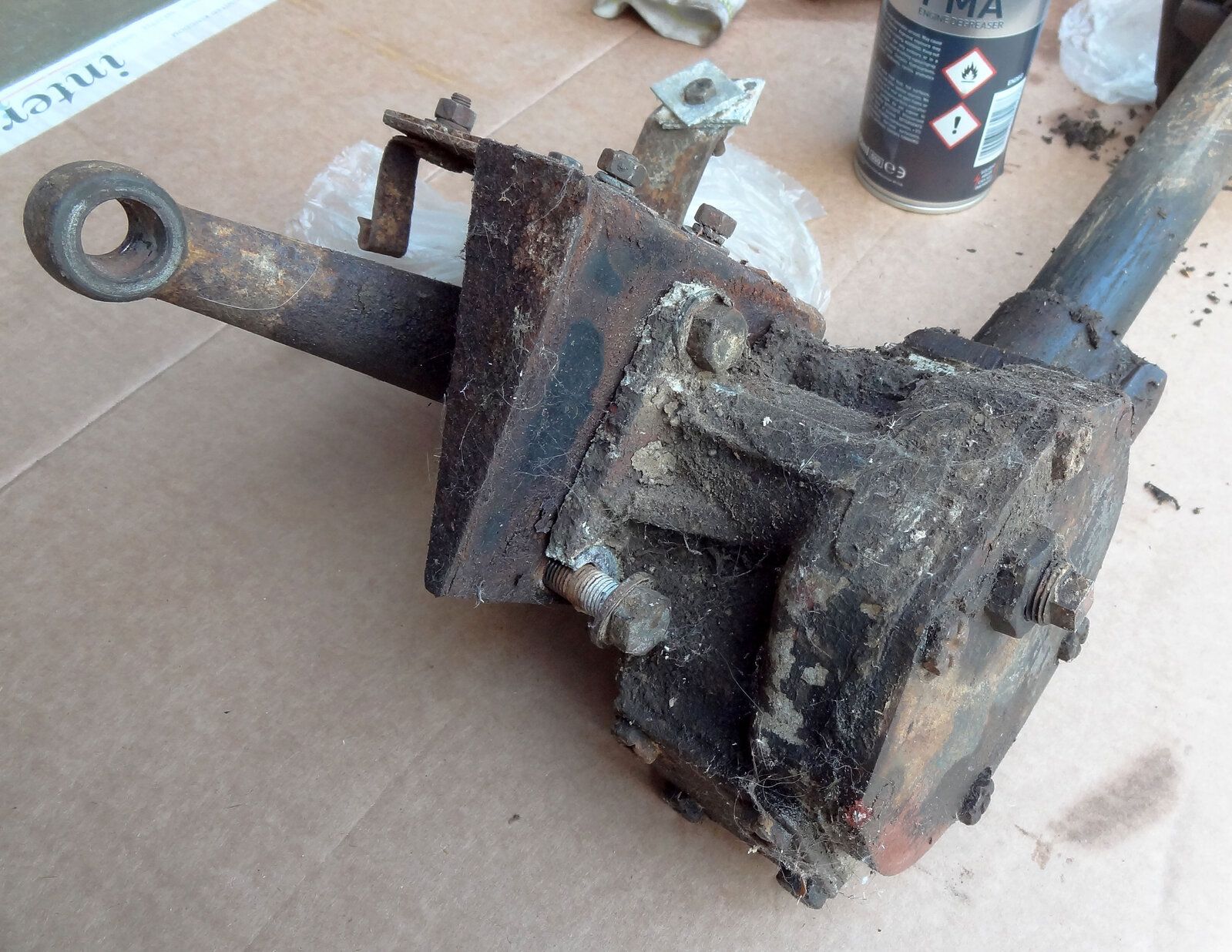

On to the steering box next and guess what? It's in a bad way.

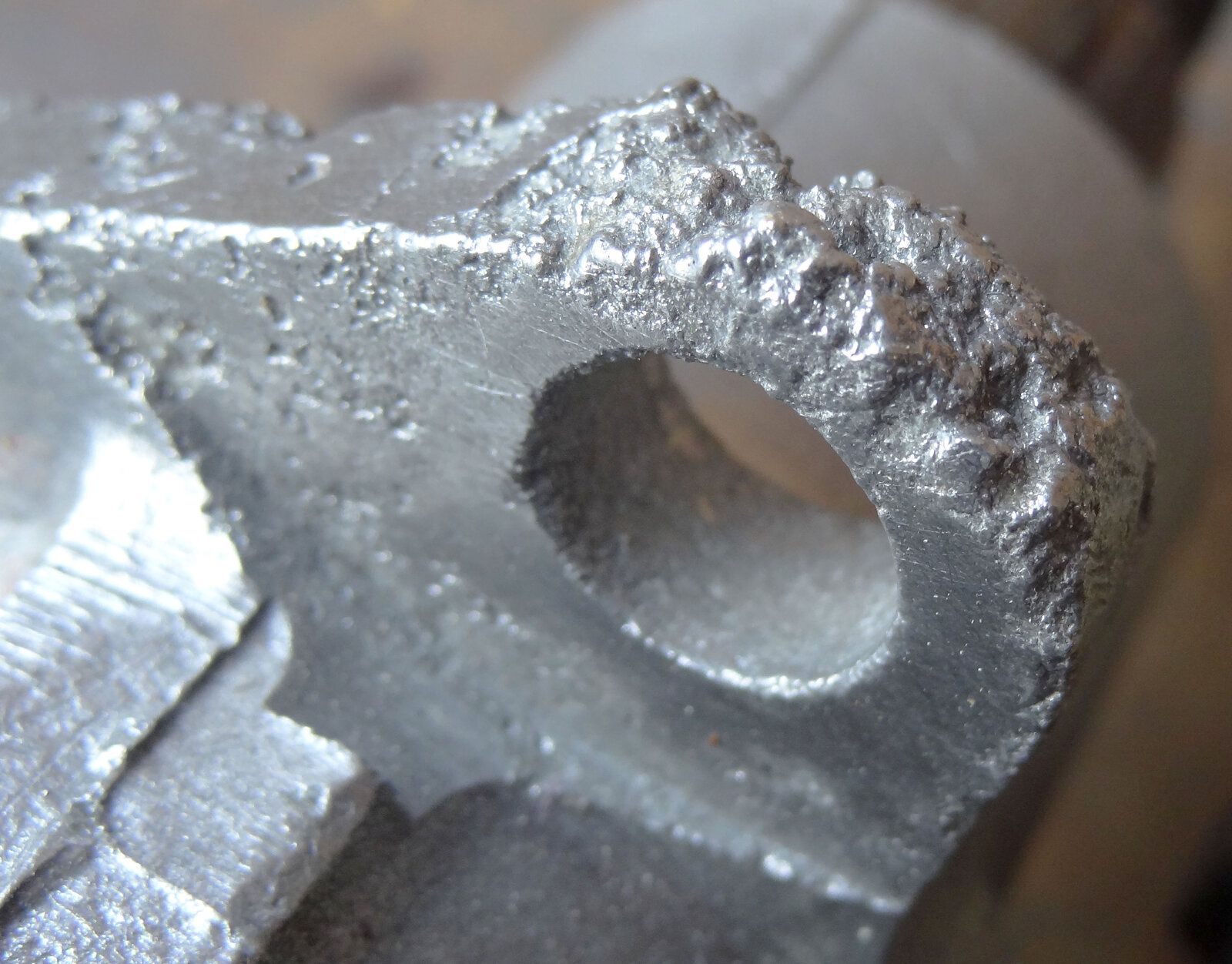

The main problem is the broken bolt hole.

It did clean up a bit and there seemed to be some hope.

I'm not sure if the damage is all down to the aluminium touching steel or if it's a bad casting. I took the dremel to it to remove the nastiness and it seemed to dig in in places throwing out dust before getting down to more solid metal.

These are before the dremel.

And this is after a bit of grinding

The main problem is the broken bolt hole.

It did clean up a bit and there seemed to be some hope.

I'm not sure if the damage is all down to the aluminium touching steel or if it's a bad casting. I took the dremel to it to remove the nastiness and it seemed to dig in in places throwing out dust before getting down to more solid metal.

These are before the dremel.

And this is after a bit of grinding

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

I looked at replacement castings but the choices weren't great. Nobody seems to sell just the casting. You can get entire replacement boxes and columns for between £400 to £600 or dodgy looking second hand items from ebay for £150 to £200 that you then have to go and collect from the other end of the country because they are too heavy to post. Chances are that they will have problems of their own as well. They're all 40+ years old after all. I can't afford or don't like the look of any of those options. I did see one fella in Cyprus who was selling a new old stock casting for £200 still in it's box. That would have been great but it's too dear.

Then I thought I would have a go with those aluminium brazing rods that i've got left from previous failed experiments. According to the youtube videos they are just the job for repairing castings. Trouble is my blow torch is not much good and couldn't get it hot enough. A new blow torch will probably cost £30 to £50 because I would want to get a good one and even then would the brazing be good enough and safe enough for steering components? So my final thought was to look for a welder who would have a go at it and do it properly. I've found a local fella who seems to have good reviews and says he thinks a couple of hours work at £30 per hour should see it done. I've left it with him and I will let you know how I get on.

Then I thought I would have a go with those aluminium brazing rods that i've got left from previous failed experiments. According to the youtube videos they are just the job for repairing castings. Trouble is my blow torch is not much good and couldn't get it hot enough. A new blow torch will probably cost £30 to £50 because I would want to get a good one and even then would the brazing be good enough and safe enough for steering components? So my final thought was to look for a welder who would have a go at it and do it properly. I've found a local fella who seems to have good reviews and says he thinks a couple of hours work at £30 per hour should see it done. I've left it with him and I will let you know how I get on.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Here's the last of the oil that came out of the steering box. Quite appropriate for the time of year how sparkly and Christmassy it looked.

auld duffer

Well-Known Member

- Posts

- 577

- Location

- scotland

I have a couple of old boxes here . I use them on some of the hot rod builds .. Pretty sure I can sort you out with a decent useable and affordable case I actually have one that I bought recently that was "rebuilt" an ebay score , rebuit meant pulled from a donor, striped and then bolted back together with the ball bearings in a zip bag taped to the column . Or what about the other rebuilt one that arrived only to be LHD and no it wasn't rebuilt either .. and I bet they knew it was a left hooker .. iI can probably scare it up and post a few pics on here if your interested.

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

That's really good of you. Thanks. Let me see what the welder says. If he can sort my one out then i'll just let him get on with it but if it's a goner i'll let you know.I have a couple of old boxes here . I use them on some of the hot rod builds .. Pretty sure I can sort you out with a decent useable and affordable case I actually have one that I bought recently that was "rebuilt" an ebay score , rebuit meant pulled from a donor, striped and then bolted back together with the ball bearings in a zip bag taped to the column . Or what about the other rebuilt one that arrived only to be LHD and no it wasn't rebuilt either .. and I bet they knew it was a left hooker .. iI can probably scare it up and post a few pics on here if your interested.

I've also got a bit of an obsession with trying to reuse as many original bits as possible even when it's not really sensible. That comes from early on when I realised i'd been a bit of a burk and bought a really terrible land rover. I reasoned that if I could get it back on the road with most of it's original bits still on then it hadn't been quite such a massive up-cock after all.

auld duffer

Well-Known Member

- Posts

- 577

- Location

- scotland

It sounds like were all in the same boat. I always think I will put a bad purchase down to experience . Turns out I never learn and jump from one bad experience to the next . Over 40 odd years of bad purchases you eventually just come to expect a disaster . The fun or satisfaction is in recovering the old junk and quietly realise when you stand back and look at it that you made something from nothing. We have to remember as well that the stuff we saved will outlast us in most cases ..

Similar threads

- Replies

- 9

- Views

- 763

- Replies

- 5

- Views

- 534

- Replies

- 2

- Views

- 518