Hi all,

Just started to change the cambelts on my Freelander and come across a problem that we cannot work out!

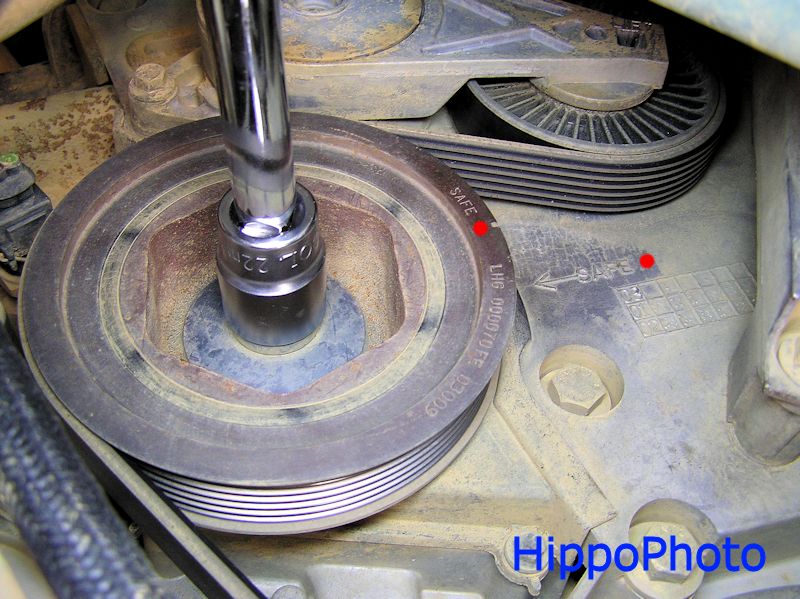

The story so far is that we moved the engine round to the safe mark and put the locking pin into the fly wheel. All good so far. We checked the other side of the cam shafts on the front bank as the rave disc said and it was all lined up just as it should be.

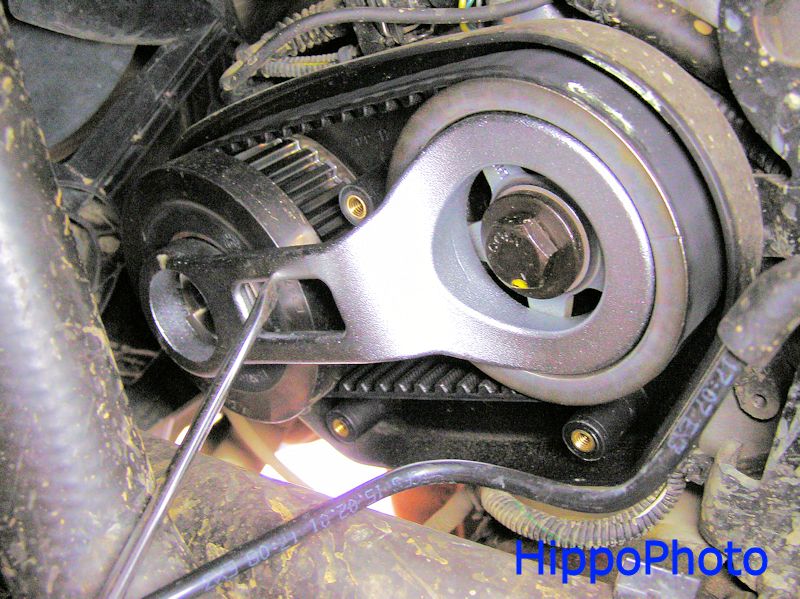

We then locked the camshafts with the laser locking tools ready to change the main belt.

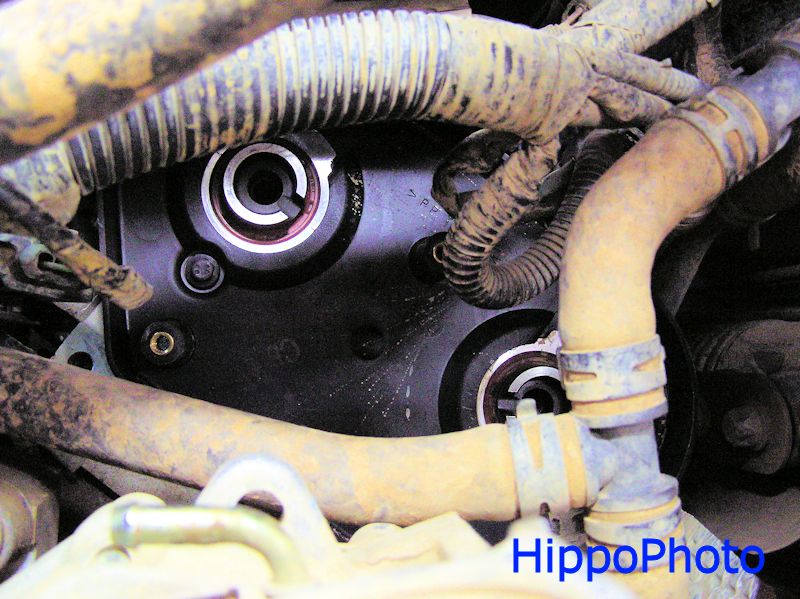

We then noticed that the tool located perfectly into the camshaft and the exhaust port on the front bank but was out on the rear.

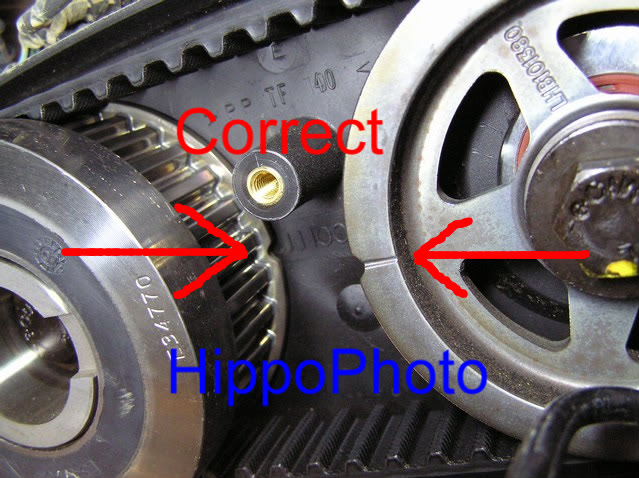

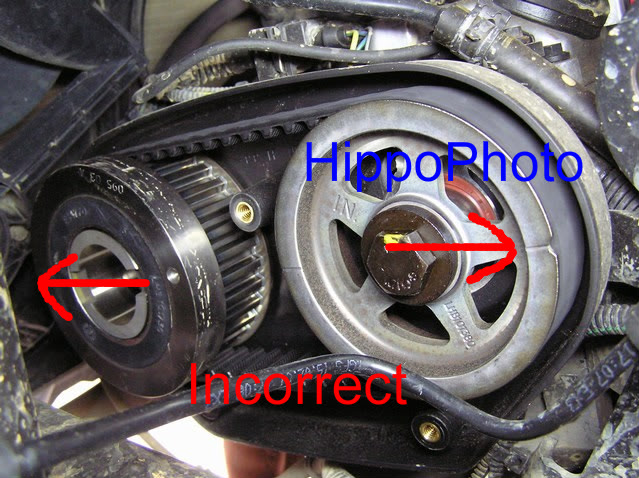

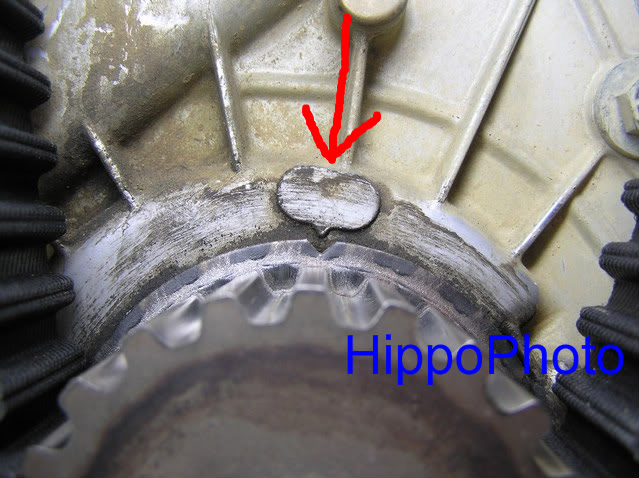

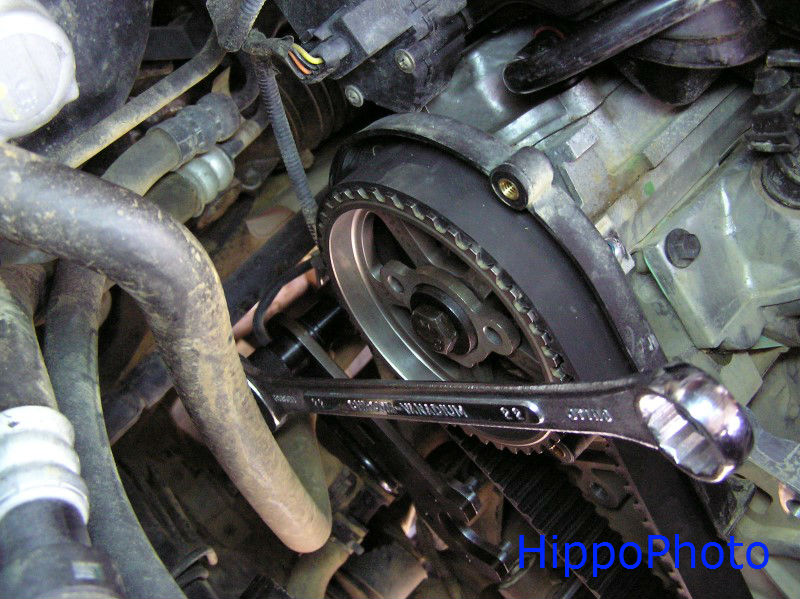

On removing the back banks cover (where the short belt is) we noted that it was not lined up. We removed the cambelt and moved the cam shafts round and realised that there is no way it would ever rest on the notches on the camshaft pulleys, the marks seem to be put the camshafts in a position where the vales are half way through a cycle.

The engine ran fine before starting this and we are at a loss as to what has gone wrong and how we change the belts!

Any information would be fantastic!

Just started to change the cambelts on my Freelander and come across a problem that we cannot work out!

The story so far is that we moved the engine round to the safe mark and put the locking pin into the fly wheel. All good so far. We checked the other side of the cam shafts on the front bank as the rave disc said and it was all lined up just as it should be.

We then locked the camshafts with the laser locking tools ready to change the main belt.

We then noticed that the tool located perfectly into the camshaft and the exhaust port on the front bank but was out on the rear.

On removing the back banks cover (where the short belt is) we noted that it was not lined up. We removed the cambelt and moved the cam shafts round and realised that there is no way it would ever rest on the notches on the camshaft pulleys, the marks seem to be put the camshafts in a position where the vales are half way through a cycle.

The engine ran fine before starting this and we are at a loss as to what has gone wrong and how we change the belts!

Any information would be fantastic!