My autobox Disco Td5 developed a slight shiver just before every gear change, between 2200-2800 rpm. Over the past 6 months the shudder gradually turned into a harsh vibration, eventually sounding like coarse gravel agitated in a tin can type of noise. ATF & filter checked and replaced regularly. No abnormal slipping or other autobox issues. No fault codes stored in EAT ECU.

Historically Td5 torque converters fail by cracking at the base plate but upon a visual check through the opening in the bottom of the bell housing confirmed no visible cracks or missing bolts at the TC which TBH was a bit discouraging

In addition to being a mechanical weak point, the Td5 T/C suffers from an excessively high stall speed (~2800 rpm) which is better suited for a petrol engine (Td5 engine torque peaks at around 2200 rpm). Many owners concur in that the Td5 autobox changes gears too late causing the engine to rev up unnecessarily (throwing gears well above 3000 rpm under medium to heavy acceleration), giving the feel of one being rather driving a 140HP outboard and not a modern diesel engine. A fellow autobox Td5 owner did in fact coin the term speedboat effect to best describe this phenomenon.

So in order to hopefullyfix the vibration problems, get rid of the speedboat effect, and eliminate the known weakness between engine and transmission (thinking of future remap), opted to replace the torque converter for an uprated version from Ashcroft Transmissions. This is nothing but the T/C used for the 3.9 & 4.0 P38s but with a sturdier billet base plate modified to match the triangular 3-bolt flex plate on the Td5 as well as an altered spigot to fit the 4HP22 oil pump. With a lower stall speed (2200 rpm) it is meant to provide torque to the transmission a lot earlier than the factory standard T/C.

Had done the Td5 clutch several times but the autobox was totally unknown territory. Went down to my mates place both for his helping hand and pit. Initially thought the job could be tackled in a day if started early enough but this soon proved impossible. Ended taking a total of 20 hrs over 2 days. Encountered numerous difficulties but the complexity lied in the number of details that had to be taken care off. Getting the autobox back in with the new T/C installed and partially filled with ATF was a complete b*tch and had to call for reinforcements at this point. Reckon the whole job would have taken 4-5 days in a regular garage.

Upon reenergizing the vehicle all kinds of errors showed up, especially within the EAT ECU which did not like at all being disconnected from the autobox, and had to reset it various times before it started talking to the ECM. Filling the whole system with ATF took quite a while as there was air everywhere.

The last task on the list was resetting the adaptative values in the EAT ECU. The EAT knows the nominal time that each gear shift should take. To counteract for wear in the autobox components as well as differences in the engine torque/power vs speed delivered, the EAT monitors the pressure modulation used for each gear change and applies a pressure adaptation so that shift duration is restored to the nominal value. These adaptative pressure values are stored in a volatile memory within the EAT ECU and in this scenario I thought it necessary to wipe them clean since an essential component of the auto transmission had just been replaced. Unfortunately HawkEye was not up to the task (function not included) and had to resort to my mates DEC system.

Finally went out for a spin felt as if was driving a different vehicle!!! Not only was the infamous vibration gone but the driving completely changed! No more gear shifts at +3000 rpm, on a light throttle gears go at 1700-1800 rpm, and 2300-2400 rpm on a heavier foot. Overall the engine runs a lot smoother and even all the time.

Other noticeable changes:

1) Engine and auto transmission feel closer and more in tune rather than catching up with each other all the time (reduced T/C slippage?).

2) More inertia: the uprated T/C is roughly 2 wider and 10 lbs heavier (plus the extra ATF volume) than the original one which gives an increased flywheel effect. Engine feels firmer, solider.

3) Gear shifts are a lot smoother (likely also a consequence of having completely changed the ATF) and on T/C locking up no longer feel the slight pull-push the old T/C had, now can only tell by the drop in engine revs.

4) A totally non-anticipated yet very much welcome side effect: a significant drop in fuel consumption! Still evaluating it but would dare say between 10-15% (quick calculation shows I should be able to repay the new T/C in ~10 months). Logically without the constant revving up it had to burn less fuel.

Pictures:

All (3) available T/Cs side by side (photo from Ashcroft Transmissions), on the left the original Td5 T/C (also used on the 300 Tdi and diesel P38), in the middle the medium T/C fitted to the 3.9 and 4.0 P38s (this is the one that Ashcroft modifies for the Td5) and on the right the large one used on the 4.6 P38:

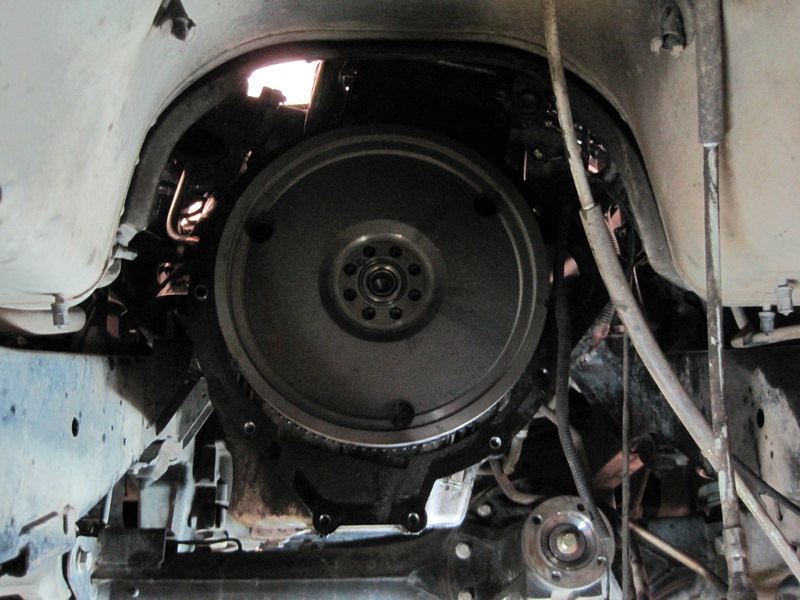

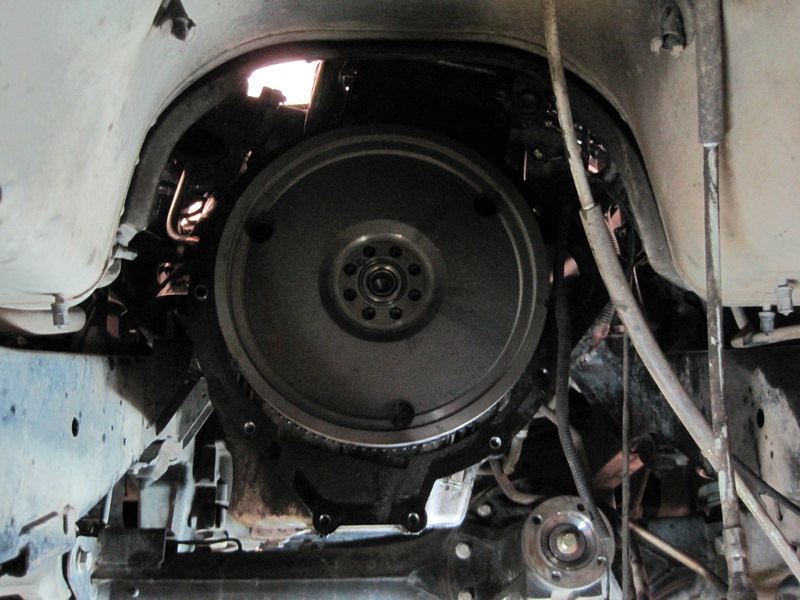

Transfer box & autobox out of the way: flywheel and flexplate:

New T/C:

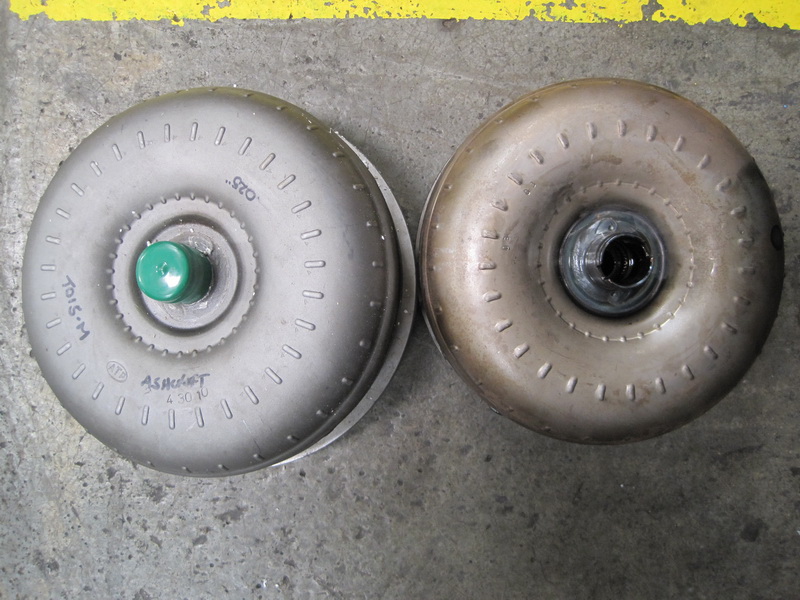

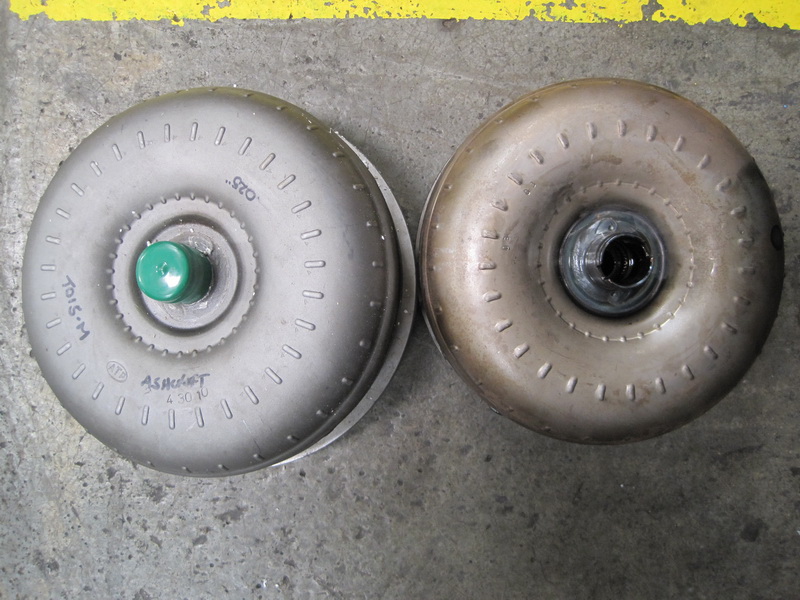

New T/C vs old one:

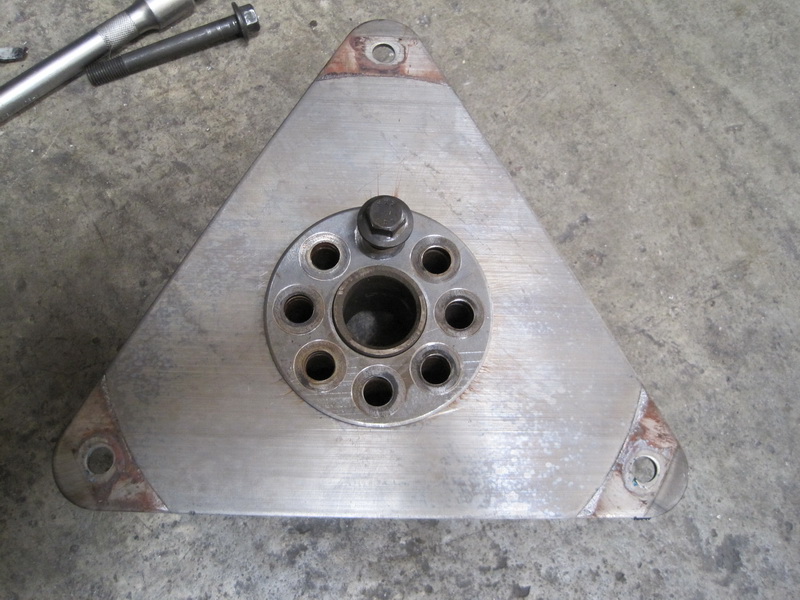

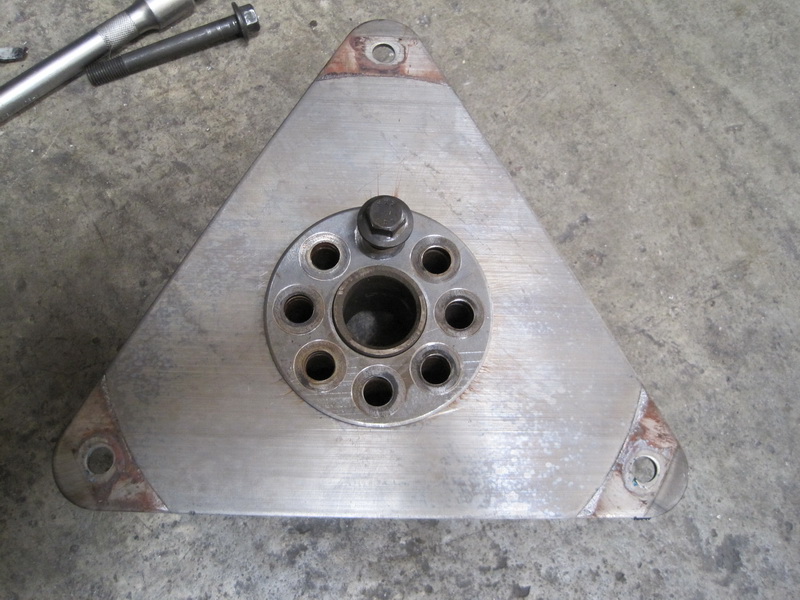

New T/C base/fix plate:

Old T/C base/fix plate:

Bowl & flex plate:

Flywheel (the holes line up with the fixing points in the flex plate, for factory mounting of T/C?):

Autobox:

New seal in converter housing:

Rgds

Matt

Historically Td5 torque converters fail by cracking at the base plate but upon a visual check through the opening in the bottom of the bell housing confirmed no visible cracks or missing bolts at the TC which TBH was a bit discouraging

In addition to being a mechanical weak point, the Td5 T/C suffers from an excessively high stall speed (~2800 rpm) which is better suited for a petrol engine (Td5 engine torque peaks at around 2200 rpm). Many owners concur in that the Td5 autobox changes gears too late causing the engine to rev up unnecessarily (throwing gears well above 3000 rpm under medium to heavy acceleration), giving the feel of one being rather driving a 140HP outboard and not a modern diesel engine. A fellow autobox Td5 owner did in fact coin the term speedboat effect to best describe this phenomenon.

So in order to hopefullyfix the vibration problems, get rid of the speedboat effect, and eliminate the known weakness between engine and transmission (thinking of future remap), opted to replace the torque converter for an uprated version from Ashcroft Transmissions. This is nothing but the T/C used for the 3.9 & 4.0 P38s but with a sturdier billet base plate modified to match the triangular 3-bolt flex plate on the Td5 as well as an altered spigot to fit the 4HP22 oil pump. With a lower stall speed (2200 rpm) it is meant to provide torque to the transmission a lot earlier than the factory standard T/C.

Had done the Td5 clutch several times but the autobox was totally unknown territory. Went down to my mates place both for his helping hand and pit. Initially thought the job could be tackled in a day if started early enough but this soon proved impossible. Ended taking a total of 20 hrs over 2 days. Encountered numerous difficulties but the complexity lied in the number of details that had to be taken care off. Getting the autobox back in with the new T/C installed and partially filled with ATF was a complete b*tch and had to call for reinforcements at this point. Reckon the whole job would have taken 4-5 days in a regular garage.

Upon reenergizing the vehicle all kinds of errors showed up, especially within the EAT ECU which did not like at all being disconnected from the autobox, and had to reset it various times before it started talking to the ECM. Filling the whole system with ATF took quite a while as there was air everywhere.

The last task on the list was resetting the adaptative values in the EAT ECU. The EAT knows the nominal time that each gear shift should take. To counteract for wear in the autobox components as well as differences in the engine torque/power vs speed delivered, the EAT monitors the pressure modulation used for each gear change and applies a pressure adaptation so that shift duration is restored to the nominal value. These adaptative pressure values are stored in a volatile memory within the EAT ECU and in this scenario I thought it necessary to wipe them clean since an essential component of the auto transmission had just been replaced. Unfortunately HawkEye was not up to the task (function not included) and had to resort to my mates DEC system.

Finally went out for a spin felt as if was driving a different vehicle!!! Not only was the infamous vibration gone but the driving completely changed! No more gear shifts at +3000 rpm, on a light throttle gears go at 1700-1800 rpm, and 2300-2400 rpm on a heavier foot. Overall the engine runs a lot smoother and even all the time.

Other noticeable changes:

1) Engine and auto transmission feel closer and more in tune rather than catching up with each other all the time (reduced T/C slippage?).

2) More inertia: the uprated T/C is roughly 2 wider and 10 lbs heavier (plus the extra ATF volume) than the original one which gives an increased flywheel effect. Engine feels firmer, solider.

3) Gear shifts are a lot smoother (likely also a consequence of having completely changed the ATF) and on T/C locking up no longer feel the slight pull-push the old T/C had, now can only tell by the drop in engine revs.

4) A totally non-anticipated yet very much welcome side effect: a significant drop in fuel consumption! Still evaluating it but would dare say between 10-15% (quick calculation shows I should be able to repay the new T/C in ~10 months). Logically without the constant revving up it had to burn less fuel.

Pictures:

All (3) available T/Cs side by side (photo from Ashcroft Transmissions), on the left the original Td5 T/C (also used on the 300 Tdi and diesel P38), in the middle the medium T/C fitted to the 3.9 and 4.0 P38s (this is the one that Ashcroft modifies for the Td5) and on the right the large one used on the 4.6 P38:

Transfer box & autobox out of the way: flywheel and flexplate:

New T/C:

New T/C vs old one:

New T/C base/fix plate:

Old T/C base/fix plate:

Bowl & flex plate:

Flywheel (the holes line up with the fixing points in the flex plate, for factory mounting of T/C?):

Autobox:

New seal in converter housing:

Rgds

Matt