Hello All,

Took my wiper motor apart to have a look inside recently - aside from a lot of old grease it looked OK mechanically, but I'm less of an expert on the electrical side of things. Some advice on whether this stuff looks knackered or not would be very welcome! Thanks in advance!

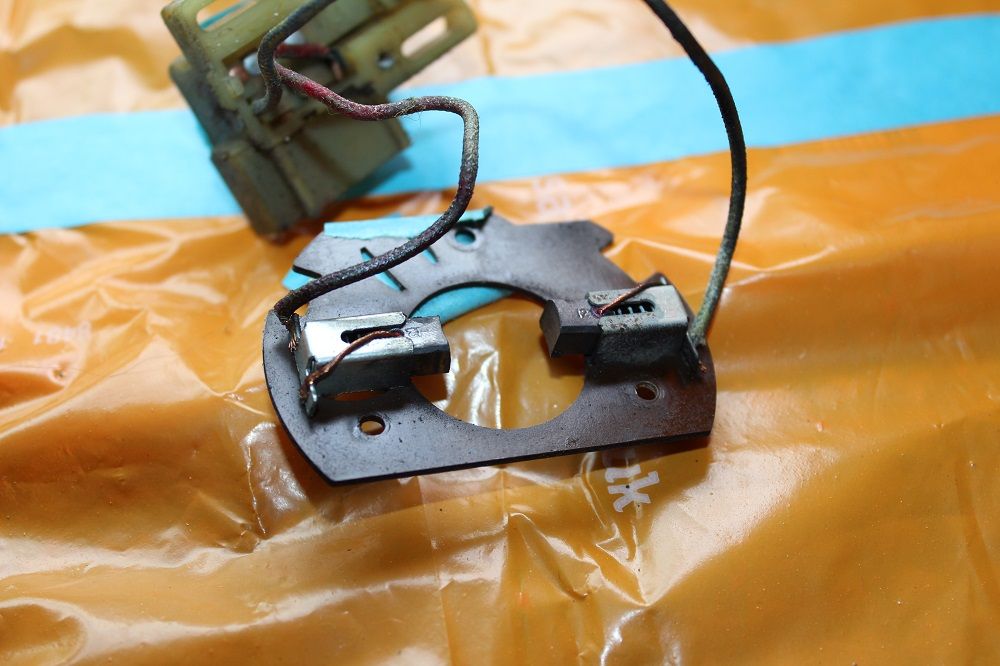

How much wear is acceptable on the brushes? I will probably replace anyway whilst I've got it apart

This magnet is cracked - I can see how it was done, as the rotor gets pulled about by the magnets as you try to refit it. Is this a showstopper - any idea where I might get a replacement?

Took my wiper motor apart to have a look inside recently - aside from a lot of old grease it looked OK mechanically, but I'm less of an expert on the electrical side of things. Some advice on whether this stuff looks knackered or not would be very welcome! Thanks in advance!

How much wear is acceptable on the brushes? I will probably replace anyway whilst I've got it apart

This magnet is cracked - I can see how it was done, as the rotor gets pulled about by the magnets as you try to refit it. Is this a showstopper - any idea where I might get a replacement?