Spacemonkey...

Well-Known Member

- Posts

- 1,048

- Location

- Darzet

Posted this a while ago on another forum, but will copy here in the hope it is of interest to someone. It's basically my Waste Veg Oil (WVO) dewatering and filtering setup. I also include the fuel heater write up I fitted to my first Pajero. My last Pajero will have a full system fitted- inline fuel heater, injector line heaters and filter pre heater, which I shall include once it is installed. I will be fitting the same setup to my Freelander L series in due course and update at the time. Hope this is useful to someone. Please feel free with any questions.

The WVO filtration system set-up! WVO is poured through a sheet that is held on the top of the drum with bungees and made into a 'cone'. (I know have a custom made filter which sits in the top of the drum and is washable). This pre-filters the large stuff out of the oil. Drum is lagged. Heater element from an immersion heater turned on for 1 hour at 70C to make the oil thin so that the water and solids separate out and sink to the bottom. The bottom layer is later removed through the bottom tap. Oil stays hot for 4 day in the summer!!! Garage smells like a chip shop during this time..

Heater in action. Mmm yummy brown smelly oil. Something smells fishy around here...

Filters. L to R- 25 micron, 10 micron, 1 micron. Filtration must be done at outside temp. This is so that any fats are solid and thus filter out. If done warm, then the fats will go through the filters and solidify in the car, thus clogging it up. Not good.. You must filter at the outside temp that you intend to use it. example, if outdoors is 10C when filtering, then only use as fuel when 10C or warmer, NOT colder, or the fats filtered at 10C could solidify at less than 10C.

The pump, a TAM 105 water pump from Machine Mart. Also shown are the taps, bottom for waste, top for good oil to be filtered. The height difference means the layers will not contaminate the good oil and the heater will never accidently be exposed to air, which can cause a fire.

Heater and waste bucket. Old oil containers used as stand. The whole project is about recycling you know..

Old oil containers from the chippy. The ones in the middle I bought fresh from a Chinese supermarket to go straight in the car once thinned with petrol. Eventually, all the processed oil will go into the Texaco drum for petrol mixing (5%) which is then wheeled to the car on a sack truck and pumped with a rotary hand pump. Takes only a few minutes to fill the car.

Oil filtration in process! Pressure gauges tell you how much the oil is flowing through the filters. When they read 0 pressure, you know the previous filter is blocked. If one reads very high then it's filter is blocked. No idea how I'm gonna change filters without a big mess because the filters don't drain... (proved not to be messy at all!!)

And into the drums. The eagle eyed will notice that the connections on the pump have been reversed. This is because I read the instructions wrong first time around... :roll:

Each 25L drum takes about 2 minutes to fill with 20L of filtered oil. This allows room for 1L of petrol to be added and shaken to mix thoroughly, to thin the veg oil to near diesel consistency. The car will have numerous fuel system heaters built on to keep the oil thin (injectors and lines, glow plug inline just before pump and water heater and filter housing. Fuel return system will preheat the tank fuel). This aids the injection pump, injectors, atomization and of course the burn itself. Veg oil only burns above 85C and preheating ensures this happens all the time. Finally, a water injection system, using the headlamp washer reservoir, will be fitted between the intercooler and the inlet manifold. This is to provide the occasional steam cleaning of the rings and combustion chamber to prevent and remove any oil 'gunge' leftover from any accidental incomplete veg oil burning from gumming up the rings, valves, crown etc. A water and methanol mix (screenwash) is injected from the headlamp washer reservoir through a high pressure Shureflow water pump into the inlet system through a 2 gallon per hour misting nozzle. The temp of the air coming in is hot enough to heat the water vapour into steam before it hits the chamber, and under compression, the steam is superheated and removes the deposits! The system will only be turned on when doing a long cruise on a motorway etc. It takes about 2 mins of injection to clean the rings properly of any old gumming, according to those that have done this. It does not affect the bore lining oil. Best done, just to be safe, on a long blast so that the whole system has plenty of time to dry out after, but probably best done just before an oil change, just to be on the safe side..

The only snag so far is the rusting of the drum. I thought the oil would prevent this and while heating tonight's batch I wiped hot oil around the whole inside of the drum. If it continues, I shall clean it out and Smoothrite the inside.

Pics of the car conversion to follow...

(In reply to a question about the process

I put Waste (Used) rapeseed veg oil in the drum. It goes in the drum to be heated which makes the water and solids separate out and sink to the bottom. The higher tap which is attached to the pump is above this layer so only clean, dry oil comes out. As you know, liquid water cannot compress so is very bad news in a diesel engine. The filters then remove fats that are solid at room temp down to 1micron. Car fuel filters do 10 micron so runs nicely. Basicaly, I am cleaning used waste veg oil (WVO) which is free and then using is as I would new straight veg oil (SVO) which is 80p a litre.

Heated, tapped drum, filter setup etc cost about £100-150 in parts, and I assembled it. Fuel line heater cost £100 which I fitted today. Paj takes 95 litres to fill. During the winter I will fill up twice a week at least. I get the used oil for free and add 1 litre of petrol to every 20 litres of oil. So one tank of my fuel costs me about 5 litres of petrol which is about £5.60, thus saving about £90 per fill up. Three tankfulls and the project is paid for. I also sell the 20 litre veg oil/petrol drums for £10, which can be poured into my friends unmodified pajeros and similar with 60 litres diesel. They get 20 litres at less than half price saving £12 per fill up.

So it certainly makes economical sense. :quite:

I have two Chinese take away chip shops that supply me all their old oil, and I'm working on the towns biggest Chinese restaurant, and then all the other Chinese places. Yesterday, I was walking through Bournemouth town centre and saw a drum of used oil outside a restaurant. I popped in and asked them if I could have it, which they said yes, but were wondering why on earth I would want it.. To me, that would be like if you found 15 litres of diesel.

So it's very worth it, very green, and it's recycling you know... :mg_bow:

Here, you used to have to pay tax on it when used as car fuel, but it still worked out cheaper than diesel by a long way. Then about 3 years ago the law changed- if you use less than 2500 litres a year- no tax. If you collect and filter less than 5000 litres a year, you don't have to register as a waste collector/disposer. I still print out the standard Gov waste collection receipts which I give to my oil providers which state I am exempt and the exemption code for registration. All quite 100% legal. Which takes all the fun out of it..

Sadly, modern cars like your PD engined Skoda can't run on veg, but CAN run very nicely indeed on home made biofuel, but there's lots of chemistry and hassle in making that stuff. I can;t be bothered. The ultra high fuel pressures in common rail engines prevents veg oil use as the pressure forces the oil to polymerise (the hard deposits on the outside of chip pans) within the fuel systems which kill it. No amount of fuel heating will prevent that.

The WVO filtration system set-up! WVO is poured through a sheet that is held on the top of the drum with bungees and made into a 'cone'. (I know have a custom made filter which sits in the top of the drum and is washable). This pre-filters the large stuff out of the oil. Drum is lagged. Heater element from an immersion heater turned on for 1 hour at 70C to make the oil thin so that the water and solids separate out and sink to the bottom. The bottom layer is later removed through the bottom tap. Oil stays hot for 4 day in the summer!!! Garage smells like a chip shop during this time..

Heater in action. Mmm yummy brown smelly oil. Something smells fishy around here...

Filters. L to R- 25 micron, 10 micron, 1 micron. Filtration must be done at outside temp. This is so that any fats are solid and thus filter out. If done warm, then the fats will go through the filters and solidify in the car, thus clogging it up. Not good.. You must filter at the outside temp that you intend to use it. example, if outdoors is 10C when filtering, then only use as fuel when 10C or warmer, NOT colder, or the fats filtered at 10C could solidify at less than 10C.

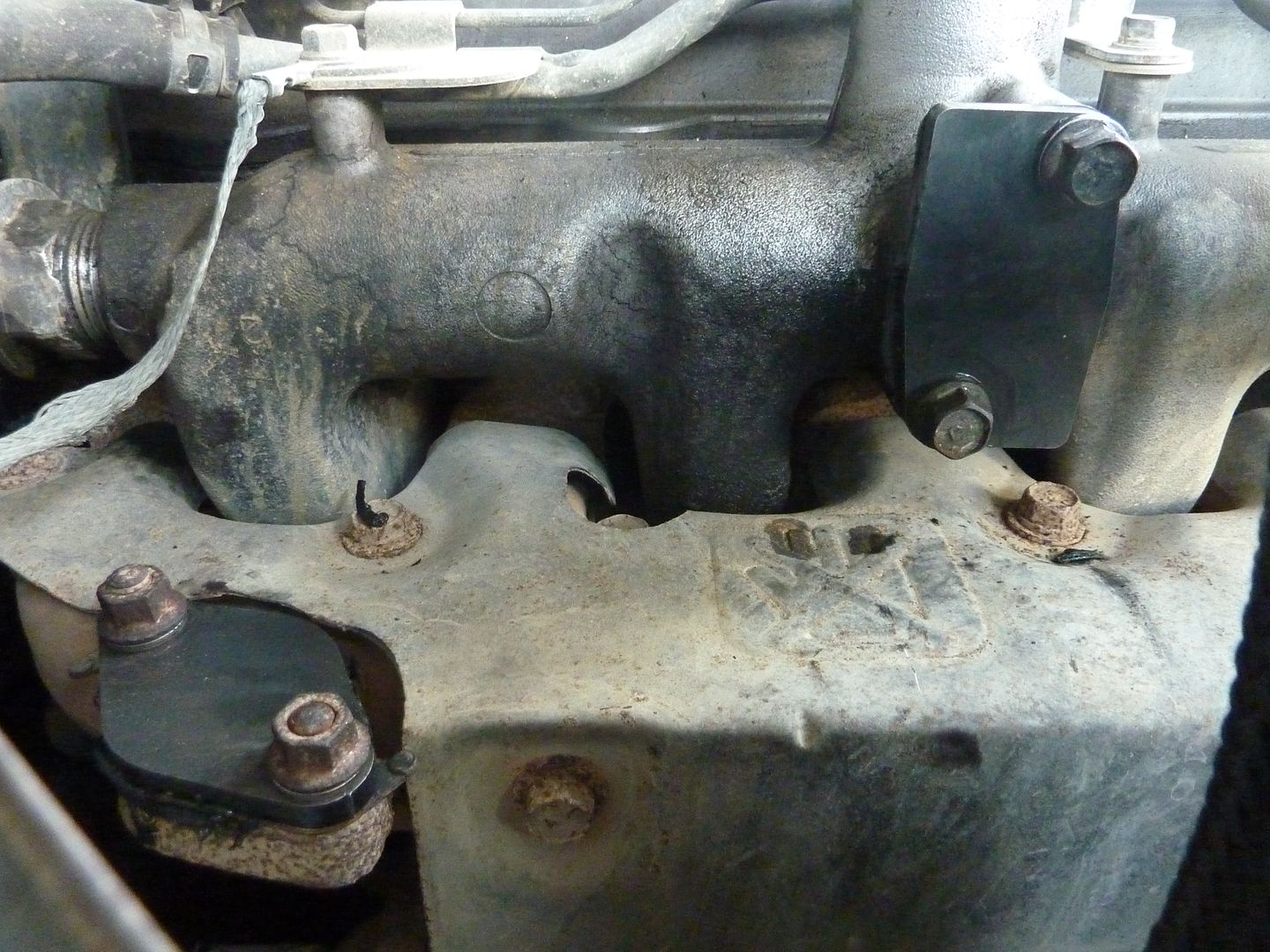

The pump, a TAM 105 water pump from Machine Mart. Also shown are the taps, bottom for waste, top for good oil to be filtered. The height difference means the layers will not contaminate the good oil and the heater will never accidently be exposed to air, which can cause a fire.

Heater and waste bucket. Old oil containers used as stand. The whole project is about recycling you know..

Old oil containers from the chippy. The ones in the middle I bought fresh from a Chinese supermarket to go straight in the car once thinned with petrol. Eventually, all the processed oil will go into the Texaco drum for petrol mixing (5%) which is then wheeled to the car on a sack truck and pumped with a rotary hand pump. Takes only a few minutes to fill the car.

Oil filtration in process! Pressure gauges tell you how much the oil is flowing through the filters. When they read 0 pressure, you know the previous filter is blocked. If one reads very high then it's filter is blocked. No idea how I'm gonna change filters without a big mess because the filters don't drain... (proved not to be messy at all!!)

And into the drums. The eagle eyed will notice that the connections on the pump have been reversed. This is because I read the instructions wrong first time around... :roll:

Each 25L drum takes about 2 minutes to fill with 20L of filtered oil. This allows room for 1L of petrol to be added and shaken to mix thoroughly, to thin the veg oil to near diesel consistency. The car will have numerous fuel system heaters built on to keep the oil thin (injectors and lines, glow plug inline just before pump and water heater and filter housing. Fuel return system will preheat the tank fuel). This aids the injection pump, injectors, atomization and of course the burn itself. Veg oil only burns above 85C and preheating ensures this happens all the time. Finally, a water injection system, using the headlamp washer reservoir, will be fitted between the intercooler and the inlet manifold. This is to provide the occasional steam cleaning of the rings and combustion chamber to prevent and remove any oil 'gunge' leftover from any accidental incomplete veg oil burning from gumming up the rings, valves, crown etc. A water and methanol mix (screenwash) is injected from the headlamp washer reservoir through a high pressure Shureflow water pump into the inlet system through a 2 gallon per hour misting nozzle. The temp of the air coming in is hot enough to heat the water vapour into steam before it hits the chamber, and under compression, the steam is superheated and removes the deposits! The system will only be turned on when doing a long cruise on a motorway etc. It takes about 2 mins of injection to clean the rings properly of any old gumming, according to those that have done this. It does not affect the bore lining oil. Best done, just to be safe, on a long blast so that the whole system has plenty of time to dry out after, but probably best done just before an oil change, just to be on the safe side..

The only snag so far is the rusting of the drum. I thought the oil would prevent this and while heating tonight's batch I wiped hot oil around the whole inside of the drum. If it continues, I shall clean it out and Smoothrite the inside.

Pics of the car conversion to follow...

(In reply to a question about the process

I put Waste (Used) rapeseed veg oil in the drum. It goes in the drum to be heated which makes the water and solids separate out and sink to the bottom. The higher tap which is attached to the pump is above this layer so only clean, dry oil comes out. As you know, liquid water cannot compress so is very bad news in a diesel engine. The filters then remove fats that are solid at room temp down to 1micron. Car fuel filters do 10 micron so runs nicely. Basicaly, I am cleaning used waste veg oil (WVO) which is free and then using is as I would new straight veg oil (SVO) which is 80p a litre.

Heated, tapped drum, filter setup etc cost about £100-150 in parts, and I assembled it. Fuel line heater cost £100 which I fitted today. Paj takes 95 litres to fill. During the winter I will fill up twice a week at least. I get the used oil for free and add 1 litre of petrol to every 20 litres of oil. So one tank of my fuel costs me about 5 litres of petrol which is about £5.60, thus saving about £90 per fill up. Three tankfulls and the project is paid for. I also sell the 20 litre veg oil/petrol drums for £10, which can be poured into my friends unmodified pajeros and similar with 60 litres diesel. They get 20 litres at less than half price saving £12 per fill up.

So it certainly makes economical sense. :quite:

I have two Chinese take away chip shops that supply me all their old oil, and I'm working on the towns biggest Chinese restaurant, and then all the other Chinese places. Yesterday, I was walking through Bournemouth town centre and saw a drum of used oil outside a restaurant. I popped in and asked them if I could have it, which they said yes, but were wondering why on earth I would want it.. To me, that would be like if you found 15 litres of diesel.

So it's very worth it, very green, and it's recycling you know... :mg_bow:

Here, you used to have to pay tax on it when used as car fuel, but it still worked out cheaper than diesel by a long way. Then about 3 years ago the law changed- if you use less than 2500 litres a year- no tax. If you collect and filter less than 5000 litres a year, you don't have to register as a waste collector/disposer. I still print out the standard Gov waste collection receipts which I give to my oil providers which state I am exempt and the exemption code for registration. All quite 100% legal. Which takes all the fun out of it..

Sadly, modern cars like your PD engined Skoda can't run on veg, but CAN run very nicely indeed on home made biofuel, but there's lots of chemistry and hassle in making that stuff. I can;t be bothered. The ultra high fuel pressures in common rail engines prevents veg oil use as the pressure forces the oil to polymerise (the hard deposits on the outside of chip pans) within the fuel systems which kill it. No amount of fuel heating will prevent that.