Hi All

I'm finding dangerous bodge after dangerous bodge on this car - all by 'reputable specialist'... More on that later.

I am a bit stumped - I had a bit of a hum/vibration and was fairly sure it would be props/UJ's. I'm trying to get it spot on so I ordered two new props.

Upon removal of the rear, I realised handbrake drum was catching really slightly, however, I reckon enough to cause a hum.

I removed the handbrake case, found the whole lot dripping in oil - rear output flange seal on transfer box. The vehicle actually failed its mot on its handbrake - there were brand new shoes in there. However, as per many items, rather than addressing the transfer box leak - they just threw new shoes in!!!

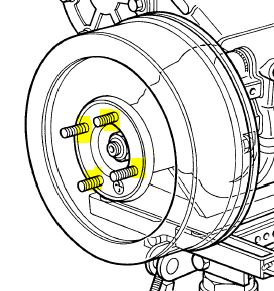

The strangest part of this, and I believe it was done at the same time will be shown in a following picture. The bolts for the output flange that secures the diff to it were tack welded on. 0 penetration, all welds broken. I'm surprised I managed to get the prop off.

How are these bolts usually secured as when looking for a new flange and seal kit, the bolt holes aren't threaded?

@jamesmartin, @Hicap phill @dieseldog69 - no doubt you've all done this job...

Thank you

I'm finding dangerous bodge after dangerous bodge on this car - all by 'reputable specialist'... More on that later.

I am a bit stumped - I had a bit of a hum/vibration and was fairly sure it would be props/UJ's. I'm trying to get it spot on so I ordered two new props.

Upon removal of the rear, I realised handbrake drum was catching really slightly, however, I reckon enough to cause a hum.

I removed the handbrake case, found the whole lot dripping in oil - rear output flange seal on transfer box. The vehicle actually failed its mot on its handbrake - there were brand new shoes in there. However, as per many items, rather than addressing the transfer box leak - they just threw new shoes in!!!

The strangest part of this, and I believe it was done at the same time will be shown in a following picture. The bolts for the output flange that secures the diff to it were tack welded on. 0 penetration, all welds broken. I'm surprised I managed to get the prop off.

How are these bolts usually secured as when looking for a new flange and seal kit, the bolt holes aren't threaded?

@jamesmartin, @Hicap phill @dieseldog69 - no doubt you've all done this job...

Thank you