Mr Freedom

Member

- Posts

- 92

- Location

- France

Hello, from SW France. Had our 2010 CSW serviced in Brighton last week and drove back to France yesterday. On the way, the handbrake light came on, for no good reason. It now comes on when the hand brake is down, and goes off when the hand brake is up! In the early hours of this morning, with a couple of miles to go, the headlights decided to switch themselves off, I could only keep them on by applying constant pressure to the lever ... Both, I would guess, are independent short circuits? A coincidence though that both should occur on the same day?

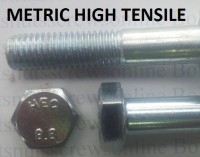

I had a drop bar and Ball'n'pin delivered from paddocks while in Brighton. To assemble, I'm instructed to apply various torques 56, 92, 240, 244Nm. I don't have a torque wrench and my local outlet only sell them up to 210Nm. I'm thinking to just tighten bolts as much as I can without overly straining myself - as a rule of thumb is this acceptable? Unfortunately, neither drop bar nor Ball'n'pin came with bolts to attach the two things together - what!? Instructions say to use Grade 8.8 M16 bolts and grade 8 nuts, now, I don't really know what that means, the bolts in my local outlet look pretty generic and don't have 'specs' on them - does everyone use the recommended?

In other news, I crashed our defender on a French motorway a week ago. My fault, I went to overtake and there was someone there ... Nobody injured thankfully. Defender drove off with a tiny mark on bumper, small scrape on wheel trim, and a small scrap on one door hinge. The Renault Cleo did not fair so well ...

I had a drop bar and Ball'n'pin delivered from paddocks while in Brighton. To assemble, I'm instructed to apply various torques 56, 92, 240, 244Nm. I don't have a torque wrench and my local outlet only sell them up to 210Nm. I'm thinking to just tighten bolts as much as I can without overly straining myself - as a rule of thumb is this acceptable? Unfortunately, neither drop bar nor Ball'n'pin came with bolts to attach the two things together - what!? Instructions say to use Grade 8.8 M16 bolts and grade 8 nuts, now, I don't really know what that means, the bolts in my local outlet look pretty generic and don't have 'specs' on them - does everyone use the recommended?

In other news, I crashed our defender on a French motorway a week ago. My fault, I went to overtake and there was someone there ... Nobody injured thankfully. Defender drove off with a tiny mark on bumper, small scrape on wheel trim, and a small scrap on one door hinge. The Renault Cleo did not fair so well ...