Jayridium

Well-Known Member

- Posts

- 1,416

- Location

- Pedronapper (Peterhead)

Long story short I have had to helicoil some of the threaded holes for the injector studs, and the studs threads weren't brilliant, so I've dressed them with a thread file and or chased them with a die as required, but I'm not 100% happy with them. I really dislike the idea of less than perfect studs going into helicoiled holes.

Yes, I know I can get replacements, but they are ~£37 a set 10 years ago, and dealer only, and we are locked down. And as these studs need removed to remove the rocker cover, and they've got the nut half way down, these could be in and out a few times, and personally I think of a helicoil as a set it and forget it, not something I want to be running revisiting...

So; I'm toying with the idea of thread-locking generic / home made m6 studs into the head, cutting the original studs to salvage the captive sleeves, which are held captive by the rolled threads head side of the studs. Then once I've retrieved those little sleeves I'd set about enlarging the holes to go over the threads on the new permanently attached studs.

Then for reassembly I'd fit the rocker cover by sliding down the studs, then put on the sleeves, and securing them with large flanged nuts over these new permanent studs. Then fit the injectors & collars, which would also go over the new permanent studs and be secured with more large flanged nuts.

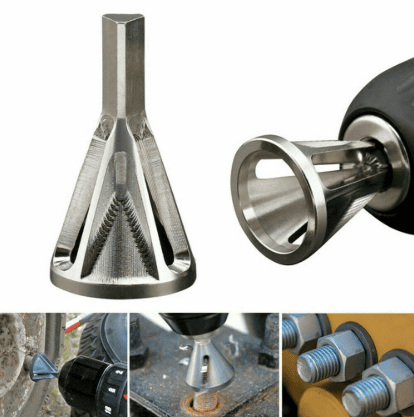

I've got some cute little M6 stainless machine screws which with an angle grinder could be decapitated to make studs, and with my lovely little chamfering tool like this one:

...they'd be quite nice when permanently affixed.

But, with the original studs being rolled threads, I'm having second thoughts... The rolled threads suggest to me that these are high tensile? So; I don't know what grade of bolt I'd need for this to work? Would the A2 marine stainless fasteners be sufficient? If not, what about grade 8.8? Or would I need to go for 10.9?

Yes, I know I can get replacements, but they are ~£37 a set 10 years ago, and dealer only, and we are locked down. And as these studs need removed to remove the rocker cover, and they've got the nut half way down, these could be in and out a few times, and personally I think of a helicoil as a set it and forget it, not something I want to be running revisiting...

So; I'm toying with the idea of thread-locking generic / home made m6 studs into the head, cutting the original studs to salvage the captive sleeves, which are held captive by the rolled threads head side of the studs. Then once I've retrieved those little sleeves I'd set about enlarging the holes to go over the threads on the new permanently attached studs.

Then for reassembly I'd fit the rocker cover by sliding down the studs, then put on the sleeves, and securing them with large flanged nuts over these new permanent studs. Then fit the injectors & collars, which would also go over the new permanent studs and be secured with more large flanged nuts.

I've got some cute little M6 stainless machine screws which with an angle grinder could be decapitated to make studs, and with my lovely little chamfering tool like this one:

...they'd be quite nice when permanently affixed.

But, with the original studs being rolled threads, I'm having second thoughts... The rolled threads suggest to me that these are high tensile? So; I don't know what grade of bolt I'd need for this to work? Would the A2 marine stainless fasteners be sufficient? If not, what about grade 8.8? Or would I need to go for 10.9?