You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steep learning curve

- Thread starter resto_d1

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Thanks - I’ll have a 3/16 spanner in a dusty box..... somewhere.

Still a fair bit, off my head:

No doubt swivels, stubs etc but they aren’t the major stuff

- Weld up bottom of chassis box where I’ve done above repair

- Weld up fuel tank cross member

- Clean, fertan, paint rear axle

- Refit rear axle with new shocks

- Fab and weld rear cross member ends with tub supports

- Full re- bush and paint arms

- Replace broken brake lines

- Wire in loom

- Finish cleaning and paint chassis

- Front end shocks, turrets and springs

- Cambelt and relevant engine work

Jesus, not much then

There’s a lot that’s for sure. And there’s the d1. The fender seems to come along faster. Think it’s cos it’s in the dry and noise doesn’t matter. I actually had the welder sweating a bit earlier due to doing such long runs

Sheared 3 of 4 spring retainer bolts on rear earlier too - they’re captive nuts on the older ones like this. Chassis actually looks quite smart now I’ve chopped most the rot and **** welding out. Looking forward to seeing it progress.

Sheared 3 of 4 spring retainer bolts on rear earlier too - they’re captive nuts on the older ones like this. Chassis actually looks quite smart now I’ve chopped most the rot and **** welding out. Looking forward to seeing it progress.

Come on you have come this far with some great work .

.

Now I am going to throw and moral boosting idea (maybe) the defender it’s not to far away is it?

(maybe) the defender it’s not to far away is it?

Is there not space for a disco free gratis then as you say your under cover and noise not a problem.

then as you say your under cover and noise not a problem.

Just a thought.

Don’t loose the faith

J

Now I am going to throw and moral boosting idea

Is there not space for a disco free gratis

Just a thought.

Don’t loose the faith

J

Cheers mate just looked at froggats section that as usual looks bang on. I’m hoping so with the fender! I just came in from it as it ****ed me off so much! I’ve stripped a few of the bits out engine and went hunting for edc components. EDC unit is present however the throttle wire was dangling (obviously) and a lot of gear isn’t attached. Im hoping I get s bonus this month, otherwise the disco will be waiting s while!

LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Sometimes a break away from it isn't such a bad thing. Family and work stuff at the moment mean I won't be able to make any progress on my series 3 for a bit and to be honest i'm not sorry. Last time I had a good go at it I was really fed up with it. Now though I can already start to feel the urge to do a bit more. I'll give it a bit longer and i'll be as keen as ever.

You're doing great work, don't lose heart.

You're doing great work, don't lose heart.

There’s a lot of nasty work to put right on the fender, on the os rear the chassis has some **** poor work. I told the owner there’s s shopping list coming.

The underside, between rear x member and trailing arm bracket isn’t pretty. The repair panel put in, is not pretty. Bare in mind we have strengthening gussets in this location and the angled crescents in the corners. The saving grace is the suspension mount areas are ok.

There’s a touch on the spring seats but don’t think they have to come out. I’m chopping underneath one to get rid of bump stop.

I’m going to go to the drawing board and come back with a method statement on how I’ll do it lol.

Fuel tank cradle cross member.... yeah you guessed it. ****ed. But I knew that. I’m starting on the fab of that but need steel which is on list.

On a brighter note, I used a breaker, a trailing arm and a scaff pole to free up fulcrum and tidied up the motor and area a bit. Can bring axle back into place and fit fuel tank once required repairs are done. Trailing arm brackets down to front bumper area of chassis is now all complete. I do wish it was a galv chassis I was building on but that wasn’t an option and I actually think I can save this for a few years to come once filled with wax. Maybe that’s naive or maybe you t will last

The underside, between rear x member and trailing arm bracket isn’t pretty. The repair panel put in, is not pretty. Bare in mind we have strengthening gussets in this location and the angled crescents in the corners. The saving grace is the suspension mount areas are ok.

There’s a touch on the spring seats but don’t think they have to come out. I’m chopping underneath one to get rid of bump stop.

I’m going to go to the drawing board and come back with a method statement on how I’ll do it lol.

Fuel tank cradle cross member.... yeah you guessed it. ****ed. But I knew that. I’m starting on the fab of that but need steel which is on list.

On a brighter note, I used a breaker, a trailing arm and a scaff pole to free up fulcrum and tidied up the motor and area a bit. Can bring axle back into place and fit fuel tank once required repairs are done. Trailing arm brackets down to front bumper area of chassis is now all complete. I do wish it was a galv chassis I was building on but that wasn’t an option and I actually think I can save this for a few years to come once filled with wax. Maybe that’s naive or maybe you t will last

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Cracking work there as always mate.

You got a massive amount of welding to go on that then

Going to be a master fabricator by the time you're done lol

You got a massive amount of welding to go on that then

Going to be a master fabricator by the time you're done lol

Haha thanks. There’s a bit more welding to do yeah but I’d say more good chassis than shot chassis at the moment. I’m going to make a jig up and make a chassis replacement section on the bench for the nasty rear bit. Then can put in as one section and add some angle in from above to replace the gussets

I’ll sticky this if it’s use to people.

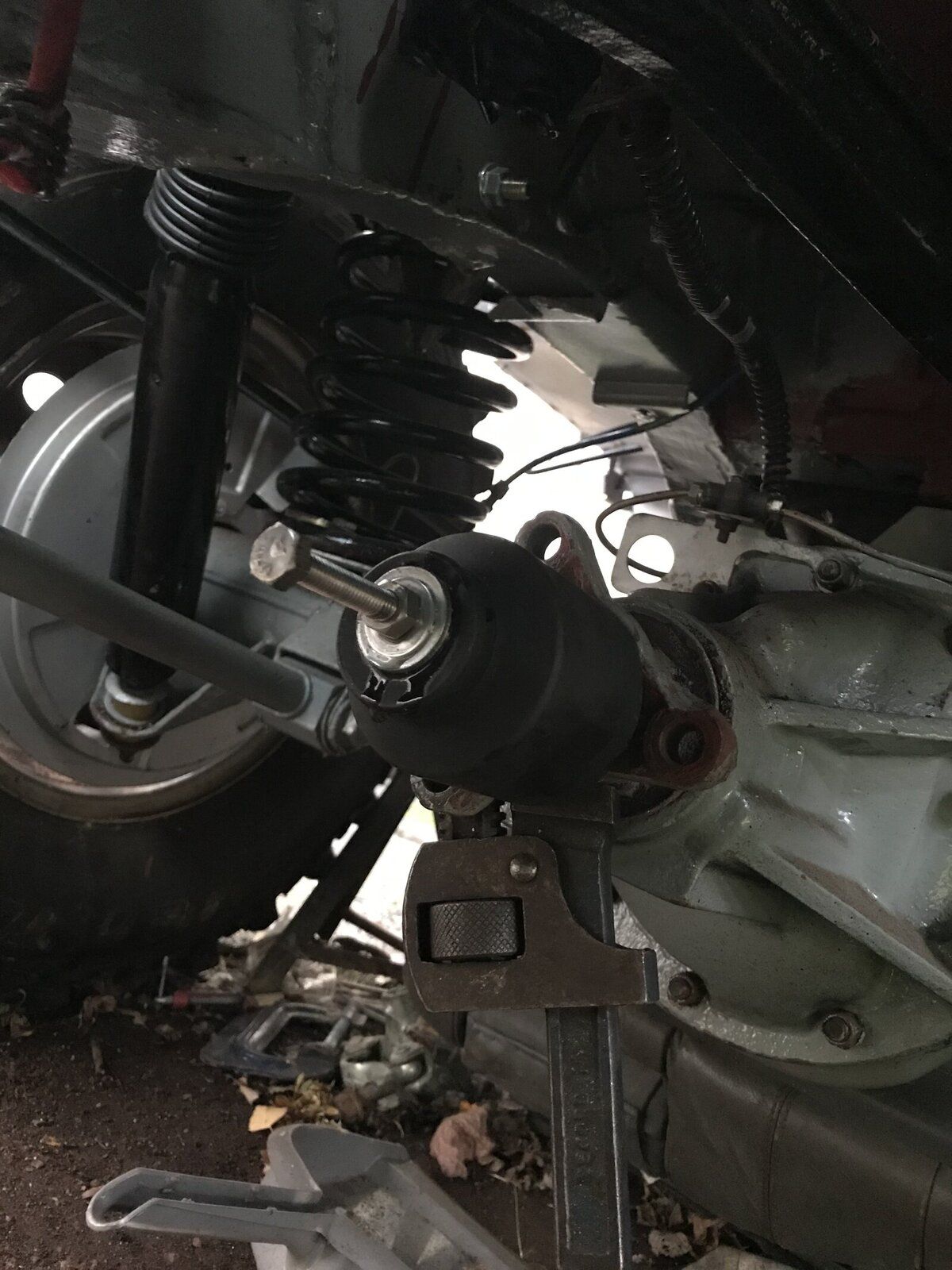

I started on this tonight but I need to use a hammer to knock seal home. Also ripped my gen seal back out looking for washer which was on 300 flange. Muppet. I got a sh1tpart one Spare but wanted my gen one in there

Once again, I followed a lr toolbox vid. he stated the spigot isn’t that tight. Mine was very tight but got there.

If you look at pics you can lock your stilsons against arms.

I used a 52mm 1/2 inch, 90mm m8 bolt, nut, washers and 3 in 1.

I started on this tonight but I need to use a hammer to knock seal home. Also ripped my gen seal back out looking for washer which was on 300 flange. Muppet. I got a sh1tpart one Spare but wanted my gen one in there

Once again, I followed a lr toolbox vid. he stated the spigot isn’t that tight. Mine was very tight but got there.

If you look at pics you can lock your stilsons against arms.

I used a 52mm 1/2 inch, 90mm m8 bolt, nut, washers and 3 in 1.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Tidy job thereI’ll sticky this if it’s use to people.

I started on this tonight but I need to use a hammer to knock seal home. Also ripped my gen seal back out looking for washer which was on 300 flange. Muppet. I got a sh1tpart one Spare but wanted my gen one in there

Once again, I followed a lr toolbox vid. he stated the spigot isn’t that tight. Mine was very tight but got there.

If you look at pics you can lock your stilsons against arms.

I used a 52mm 1/2 inch, 90mm m8 bolt, nut, washers and 3 in 1.

View attachment 191961 View attachment 191962 View attachment 191963 View attachment 191964 View attachment 191966 View attachment 191967

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Getting there.

Back must be almost sorted now, bit of seam sealing on that, top coat and it's golden.

Back must be almost sorted now, bit of seam sealing on that, top coat and it's golden.

Getting there.

Back must be almost sorted now, bit of seam sealing on that, top coat and it's golden.

yeah almost there mate! I got to do the triangle tie ins to footwell, ramped bit and the other arch then she’s good.

Will be adding box section ontop like we discussed. It will also help pull the floor away from the tank as it’s a tad saggy

- Posts

- 9,105

- Location

- Roaming the UK on assignments

yeah almost there mate! I got to do the triangle tie ins to footwell, ramped bit and the other arch then she’s good.

Will be adding box section ontop like we discussed. It will also help pull the floor away from the tank as it’s a tad saggy

I think you've done a smashing job, from no welding experience to a full on restoration, you ought feel very proud.

Thanks!

I had another couple hours before dark earlier. I thought I’d start prepping for wing repairs. Unfortunately, and after what happened to rusty, I thought I’d be cautious and remove dash and sound deadening to get at footwell and top of wing/pillar. Upon removing dash, the deafening was wet. Believe this is due to an awful design at corner of windscreen.

I got all the Land Rover chewing gum out the joins, cleaned back and painted around screen and the pillar itself.

glad I pulled dash now as can get wiring right out the way when welding and coat everything up properly.

I had another couple hours before dark earlier. I thought I’d start prepping for wing repairs. Unfortunately, and after what happened to rusty, I thought I’d be cautious and remove dash and sound deadening to get at footwell and top of wing/pillar. Upon removing dash, the deafening was wet. Believe this is due to an awful design at corner of windscreen.

I got all the Land Rover chewing gum out the joins, cleaned back and painted around screen and the pillar itself.

glad I pulled dash now as can get wiring right out the way when welding and coat everything up properly.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

That's a good shout, I have the pictures of what happens when you don't pull the matts out lol

The windscreen sealing is awful on both the 200 and 300Tdi, I'm now on the look out for another Discovery that is being broken so I can cut the windscreen posts out as my passenger side one is a bit more rotten than I thought lol

The windscreen sealing is awful on both the 200 and 300Tdi, I'm now on the look out for another Discovery that is being broken so I can cut the windscreen posts out as my passenger side one is a bit more rotten than I thought lol

Rear bumper was a bit sorry. I wanted to carry on doing bits despite rain and dark so destroyed the kitchen.

It had some filler over some heavy pitting. Have cleaned out and will get fiberglass filler to redo (non porous).

stripped down, wheeled and brushed back. Got inner coated with hammerite and hoping to prime outer tomorrow if it doesn’t rain.

It had some filler over some heavy pitting. Have cleaned out and will get fiberglass filler to redo (non porous).

stripped down, wheeled and brushed back. Got inner coated with hammerite and hoping to prime outer tomorrow if it doesn’t rain.

Similar threads

- Replies

- 1

- Views

- 687

- Replies

- 10

- Views

- 958

- Replies

- 5

- Views

- 710