RKServicing

Active Member

- Posts

- 757

- Location

- bicester

Been a busy little basterd this morning! Started to poke some holes then just went for it. Been onit since half 9....

The front half of passenger side ent to bad.

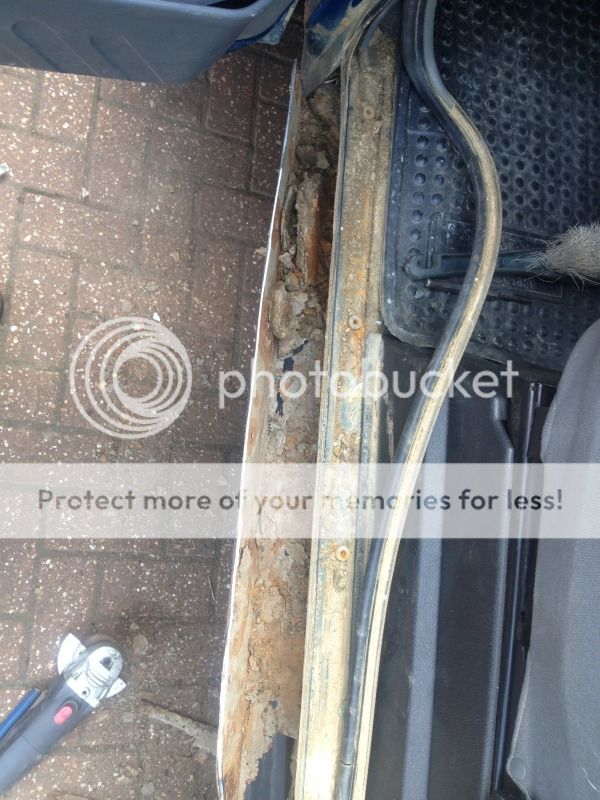

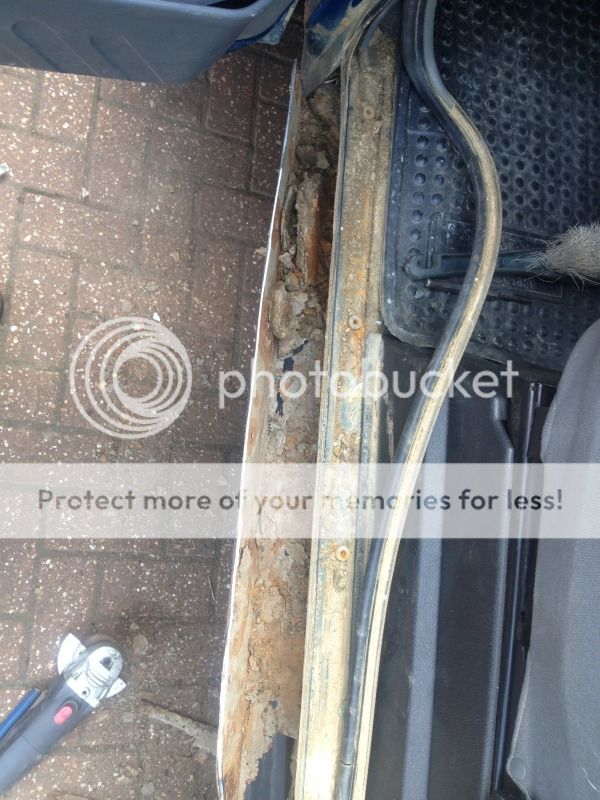

The back half not so great :O

Opened it up anyways on the front

Abit more chopping and messing resulted in this sliding straight in. Next up clean and weld, then weld on the sliders I have sat upstairs and get on with the other side!

The front half of passenger side ent to bad.

The back half not so great :O

Opened it up anyways on the front

Abit more chopping and messing resulted in this sliding straight in. Next up clean and weld, then weld on the sliders I have sat upstairs and get on with the other side!