KISSMYAURA

Well-Known Member

- Posts

- 2,817

- Location

- KENT

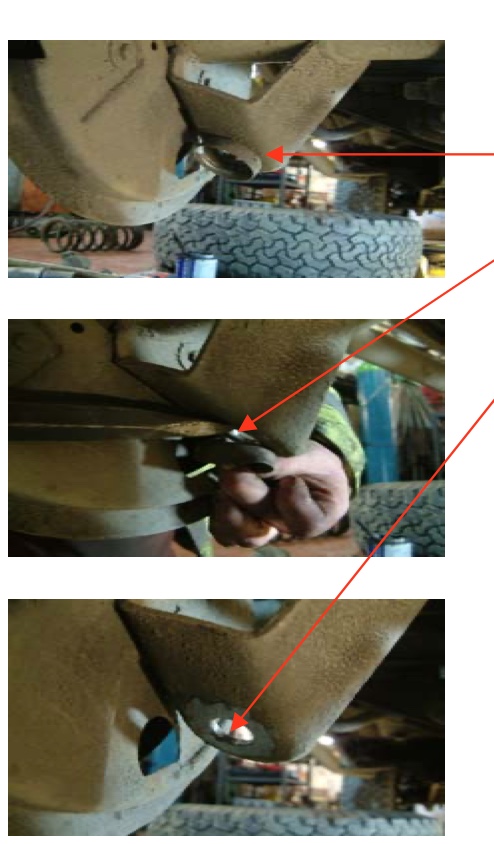

Any one shaved thier cups on the rear Shockmount to fit OME?

I was chatting with Gwyn today ( Gwyn Lewis 4x4) cos i just bought x 2 OME rear shocks from him, that was his advice.

Which i am inclined to go with however as my set is standard height and not much articulation required wondered if anyone else has done it?

I was chatting with Gwyn today ( Gwyn Lewis 4x4) cos i just bought x 2 OME rear shocks from him, that was his advice.

Which i am inclined to go with however as my set is standard height and not much articulation required wondered if anyone else has done it?