gymmaniac

Well-Known Member

- Posts

- 621

- Location

- Bedfordshire

Hi Gents,

I thought it may be useful to post a couple of photo's and comments of me replacing the original turbo on my defender 300tdi with a VNT turbo.

Getting the inlet manifold off wasn't too much of a problem.

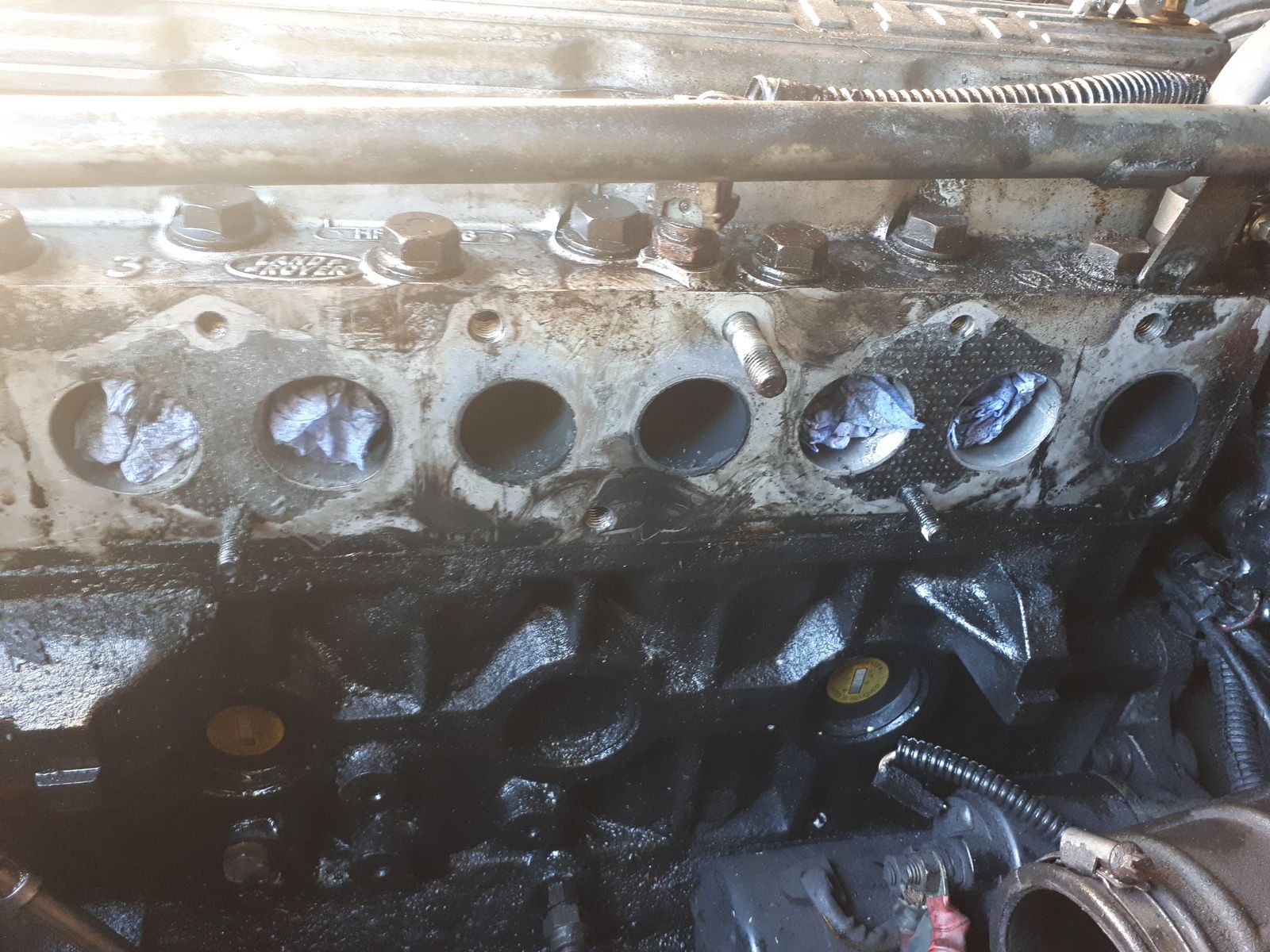

The turbo etc was a bit more tricky as the nuts connecting the exhaust were pretty corroded. Eventually using 3 extension pieces and a small breaker bar I was able to get the nuts loose from underneath the car. A fair bit of gasket was still on the head; most of this is off now thanks to a sharpened scraper. In the photo you can see cylinder 4 (and it was on 3 too) had a bit of a leak. I've also never been happy with the oil feed which needs looking at when that pipe comes off.

A bit tricky to show how badly the turbo was working. You can rattle it a millimeter or so and the gate lever is seized solid. No wonder the boost took so long to pick up and the gauge needle was rattling back and forth all the time.

Studs came out easily with two nuts applied and all the fixings look like they can be used again.

If I've still got your attention there are a couple of questions I still have:

Should I use exhaust paste on the bullhorns on the turbo?

The new turbo came with additional metal gaskets (exhaust= fine. EGR=fine. turbo oil feed = fine.) but there is an exhaust manifold gasket that only covers the center exhaust holes... but I've already got the OEM gasket that goes on the side of the head so do I need it?

If I get any replies then I'll post some extra pics etc.

thanks,

I thought it may be useful to post a couple of photo's and comments of me replacing the original turbo on my defender 300tdi with a VNT turbo.

Getting the inlet manifold off wasn't too much of a problem.

The turbo etc was a bit more tricky as the nuts connecting the exhaust were pretty corroded. Eventually using 3 extension pieces and a small breaker bar I was able to get the nuts loose from underneath the car. A fair bit of gasket was still on the head; most of this is off now thanks to a sharpened scraper. In the photo you can see cylinder 4 (and it was on 3 too) had a bit of a leak. I've also never been happy with the oil feed which needs looking at when that pipe comes off.

A bit tricky to show how badly the turbo was working. You can rattle it a millimeter or so and the gate lever is seized solid. No wonder the boost took so long to pick up and the gauge needle was rattling back and forth all the time.

Studs came out easily with two nuts applied and all the fixings look like they can be used again.

If I've still got your attention there are a couple of questions I still have:

Should I use exhaust paste on the bullhorns on the turbo?

The new turbo came with additional metal gaskets (exhaust= fine. EGR=fine. turbo oil feed = fine.) but there is an exhaust manifold gasket that only covers the center exhaust holes... but I've already got the OEM gasket that goes on the side of the head so do I need it?

If I get any replies then I'll post some extra pics etc.

thanks,