Good morning,

following my disassembly for my range with lower engine redone 12 years ago (very little driven since) but which notably lacked power, I took the compressions on my right cylinder head, 12 to 12.5 bars which is rather fine, except on the 1st where I couldn't take any compression because the spark plug threads were messed up. as I had one or more leaky injectors, that was one more reason to remove the cylinder head.

Diagnosis from my side:

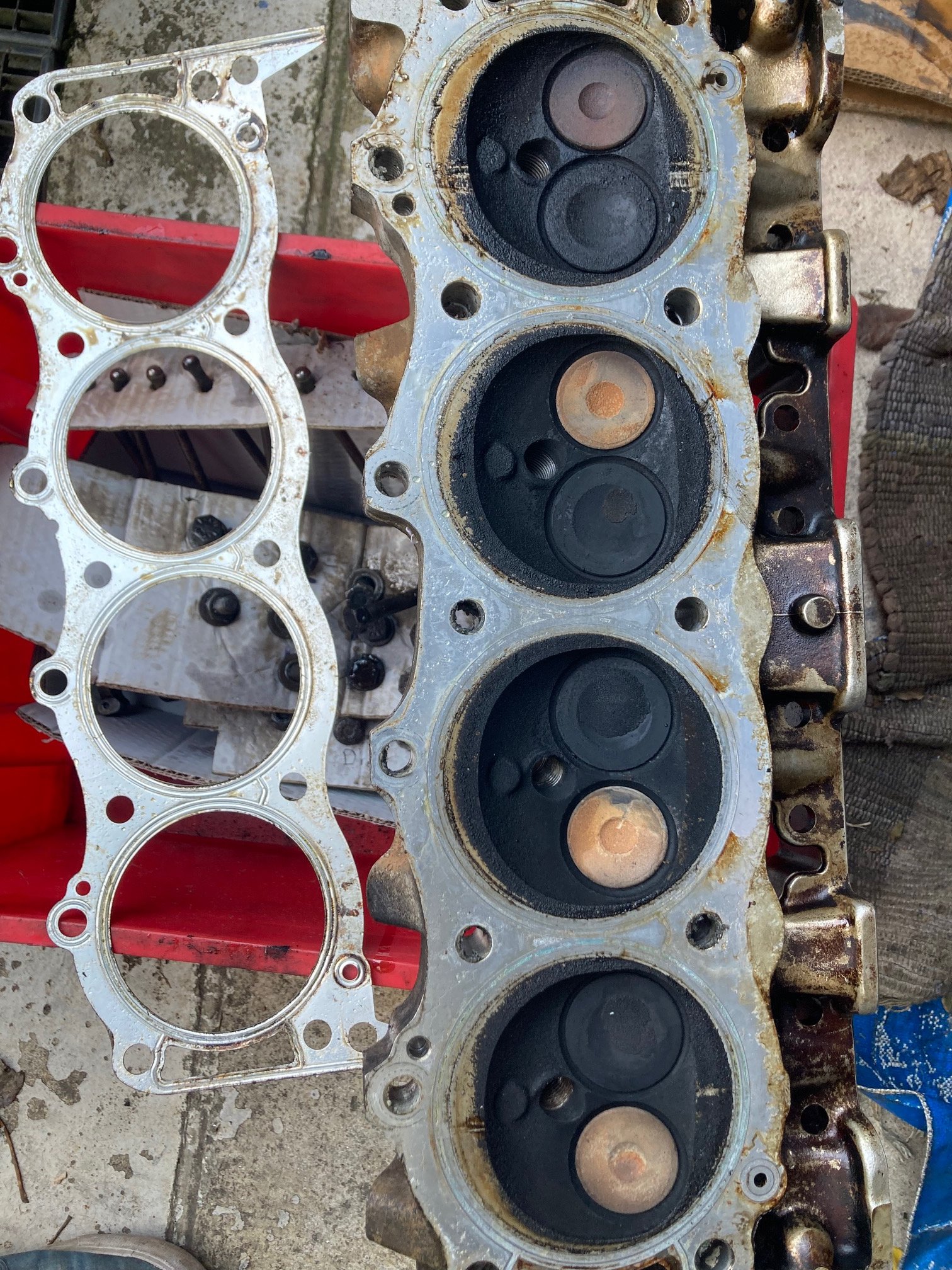

- the gasket is metal, I expected a composite, thicker because the cylinder heads were resurfaced during the 2008 repair. In any case the gasket is in good condition, apart from a little corrosion on the 1st water passage.

- The cylinder head plane also looks good to me, very slight corrosion and no visible cracks

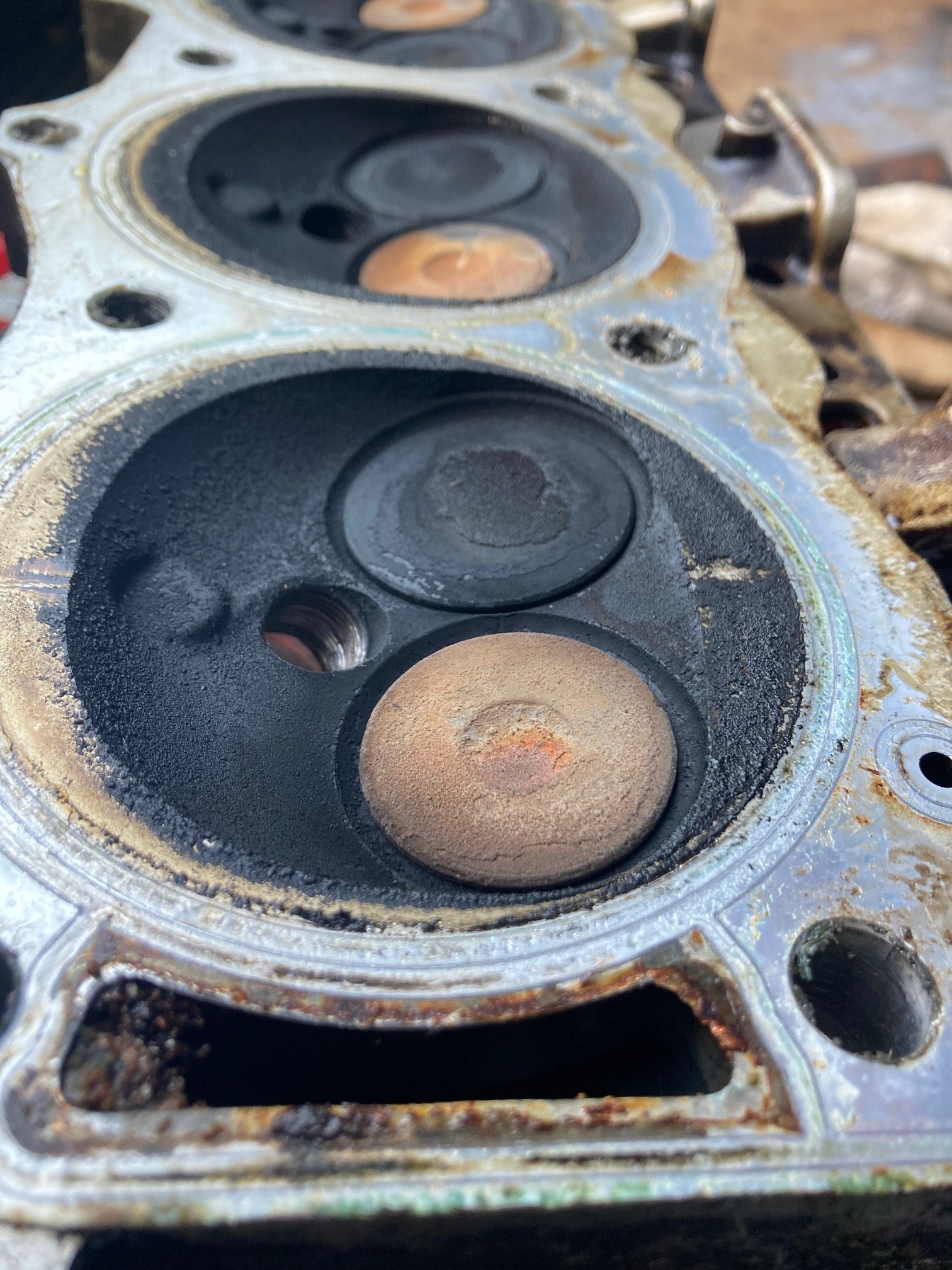

- The inlet valves are not badly carbonized although few km since the restoration (or the cylinder head had not been cleaned?) and the exhaust valves are light brown. 1st question, is it worth it to remove the valves, or just to check the tightness of the combustion chambers.

- the pistons are carbonized except on their periphery...maybe a more recent leak from the injectors?

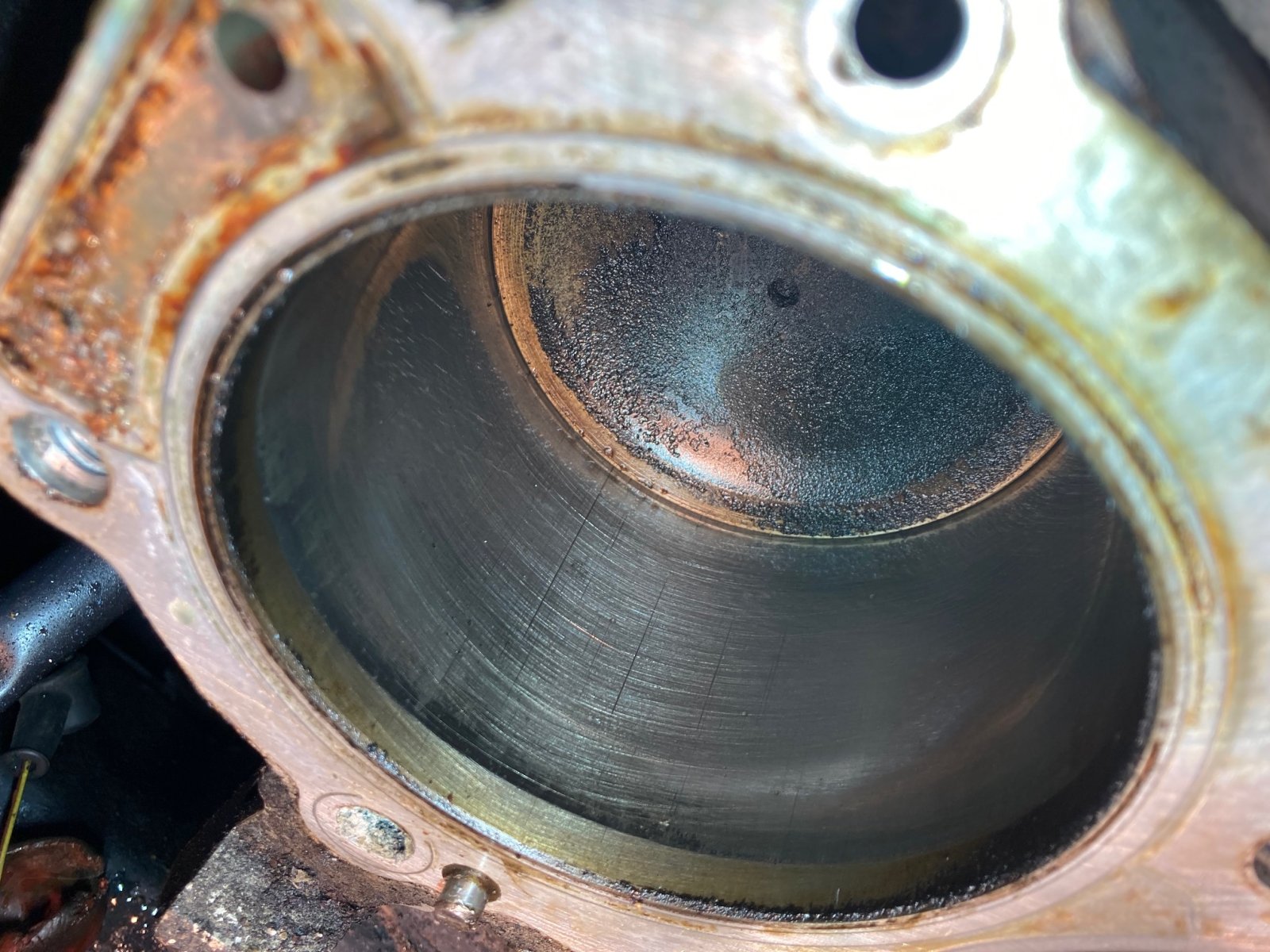

- the cylinders are scratched, and this is my biggest source of concern and questioning: very little marked horizontal scratches, and a few more pronounced vertical scratches, which can be felt when passing your fingernails...signs of the repair of 2008 which would have been badly done? origin of the loss of power of my beautiful V8?

Thank you for your feedback and your answers to my questions.

following my disassembly for my range with lower engine redone 12 years ago (very little driven since) but which notably lacked power, I took the compressions on my right cylinder head, 12 to 12.5 bars which is rather fine, except on the 1st where I couldn't take any compression because the spark plug threads were messed up. as I had one or more leaky injectors, that was one more reason to remove the cylinder head.

Diagnosis from my side:

- the gasket is metal, I expected a composite, thicker because the cylinder heads were resurfaced during the 2008 repair. In any case the gasket is in good condition, apart from a little corrosion on the 1st water passage.

- The cylinder head plane also looks good to me, very slight corrosion and no visible cracks

- The inlet valves are not badly carbonized although few km since the restoration (or the cylinder head had not been cleaned?) and the exhaust valves are light brown. 1st question, is it worth it to remove the valves, or just to check the tightness of the combustion chambers.

- the pistons are carbonized except on their periphery...maybe a more recent leak from the injectors?

- the cylinders are scratched, and this is my biggest source of concern and questioning: very little marked horizontal scratches, and a few more pronounced vertical scratches, which can be felt when passing your fingernails...signs of the repair of 2008 which would have been badly done? origin of the loss of power of my beautiful V8?

Thank you for your feedback and your answers to my questions.