Barbados

Active Member

- Posts

- 947

- Location

- Look at my name DUH LOL

Hi Mates,

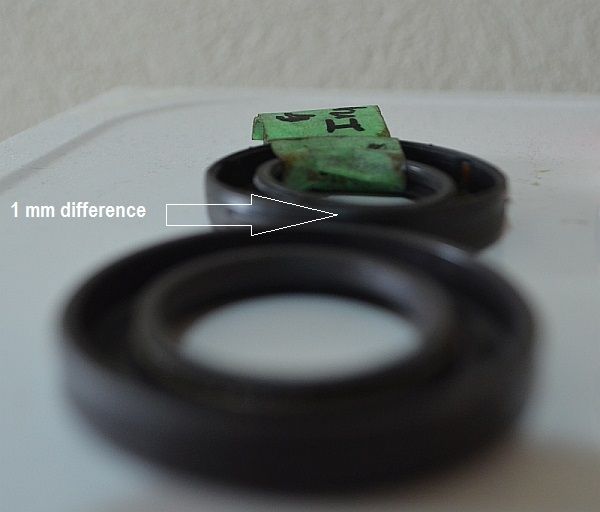

I was looking for the said seal and was sold a seal bearing the name Angus DPSM 28477V GACO 24 however,

I searched online and could not find any info on this seal.

The reason why I was looking it up, it seems to be about 1mm thinner than the original one that came off, inner and outer dia seems fine.

Not to sure how critical this is, I will still use some strong silicone on its outer diameter where it sits in the housing.

I have attached a pic, should I have any concerns, why no info online about this seal?

Cheers.

.

I was looking for the said seal and was sold a seal bearing the name Angus DPSM 28477V GACO 24 however,

I searched online and could not find any info on this seal.

The reason why I was looking it up, it seems to be about 1mm thinner than the original one that came off, inner and outer dia seems fine.

Not to sure how critical this is, I will still use some strong silicone on its outer diameter where it sits in the housing.

I have attached a pic, should I have any concerns, why no info online about this seal?

Cheers.

.