Arctic2

Well-Known Member

- Posts

- 3,026

- Location

- Westmidlands

Ok so my plans did not all go to plan, first i could not remove the Haldex pump, and or the Haldex filter, which as i said above had been replaced 8 weeks ago not 6 by the dealer to try and sort out the grabbing, where upon they added the new pump, and filter, and supposedly flushed the oil and added new Ravenol oil.

I therefore only removed the oil again by suction method, FL2 is going into Bell Engineering on the 8th January, so pump and filter will be removed then but until then i thought just do and oil change, it should not be that bad only being changed 8wks ago.

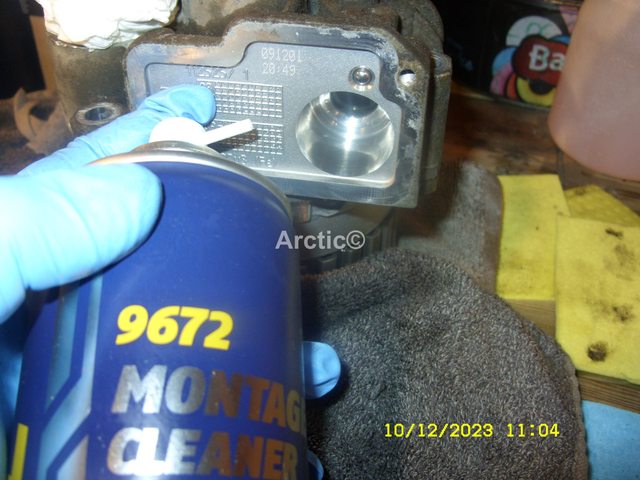

Cracked the the 13mm filler plug.

1

1

Inserted the 5mm plastic tube which is quite stiff opposed to a clear soft tube, you can direct it more into where you need to.

2

2

The was joined to the little extraction pump which was connected to the 12v battery fully charged.

3

3

The pump was started.

4

4

Oil got flowing right away.

5

5

6

6

7

7

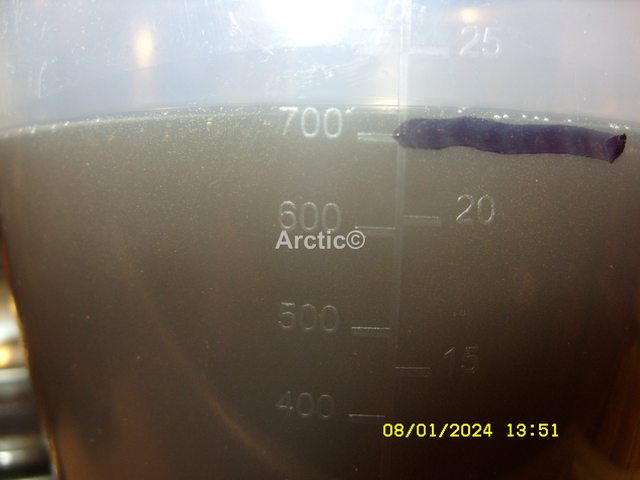

After about 15 minutes 12.30pm i had managed to remove 500ml

8

8

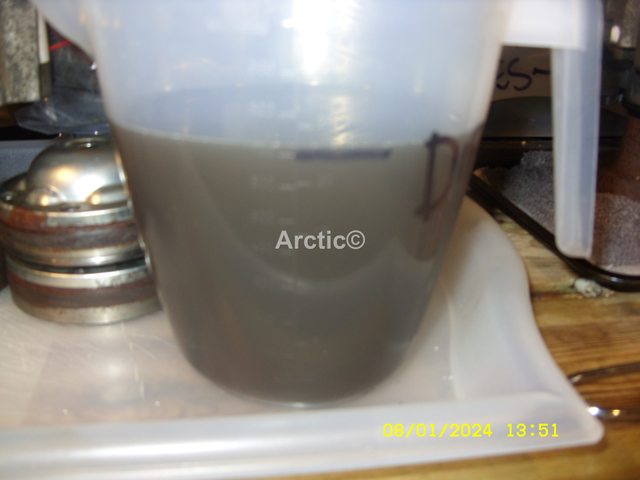

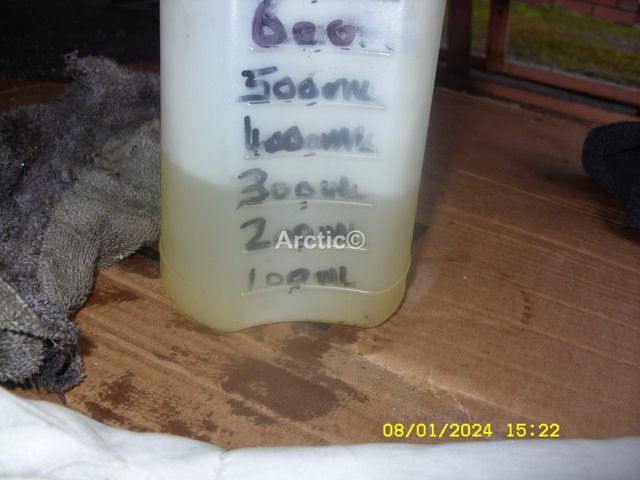

I poured this into a jug for measuring the colour does not look like 8wk old oil to me.

9

9

This is why i have not believed the seller since i purchased the car.

10

10

Anyways i filled two little pump containers with 300ml each, compare that to the oil taken out.

11

11

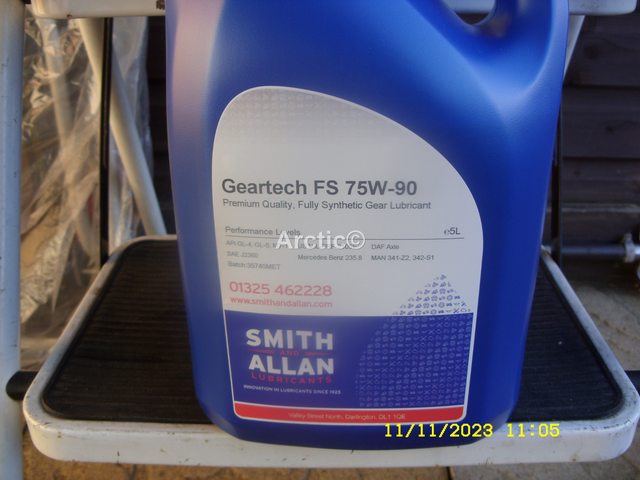

The oil used was 8100 AWD Getriebeoel

12

12

It took 600ml and no oil was over flowing out from the Haldex.

13

13

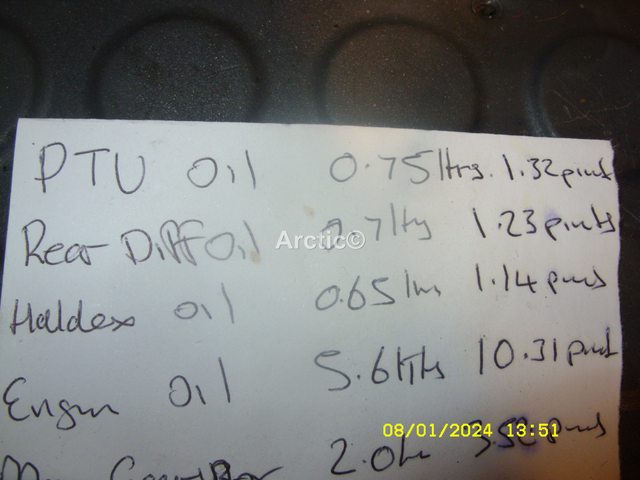

So another 100ml was added and it started to flow out, the amount it states in the hand book is 0.65litres = (1.14pints).

14

14

Filler plug was fitted so the engine could be started for about 10mins, i then removed it and sucked out 50ml, the filler plug was refitted and a magnet added to the outside.

15

15

The same has the rear diff one.

16

16

I took it for a drive and the grabbing/ scrabbling was less than before, I'm now maybe going to leave it at that until the Bell Engineering appointment, or if i do feel like it and get another good day of weather towards end of December i may drop the oil again and refill.

Would it be possible for 8wk old oil to be the colour above ?

I therefore only removed the oil again by suction method, FL2 is going into Bell Engineering on the 8th January, so pump and filter will be removed then but until then i thought just do and oil change, it should not be that bad only being changed 8wks ago.

Cracked the the 13mm filler plug.

Inserted the 5mm plastic tube which is quite stiff opposed to a clear soft tube, you can direct it more into where you need to.

The was joined to the little extraction pump which was connected to the 12v battery fully charged.

The pump was started.

Oil got flowing right away.

After about 15 minutes 12.30pm i had managed to remove 500ml

I poured this into a jug for measuring the colour does not look like 8wk old oil to me.

This is why i have not believed the seller since i purchased the car.

Anyways i filled two little pump containers with 300ml each, compare that to the oil taken out.

The oil used was 8100 AWD Getriebeoel

It took 600ml and no oil was over flowing out from the Haldex.

So another 100ml was added and it started to flow out, the amount it states in the hand book is 0.65litres = (1.14pints).

Filler plug was fitted so the engine could be started for about 10mins, i then removed it and sucked out 50ml, the filler plug was refitted and a magnet added to the outside.

The same has the rear diff one.

I took it for a drive and the grabbing/ scrabbling was less than before, I'm now maybe going to leave it at that until the Bell Engineering appointment, or if i do feel like it and get another good day of weather towards end of December i may drop the oil again and refill.

Would it be possible for 8wk old oil to be the colour above ?