alexmcrobbie

Member

- Posts

- 80

- Location

- Glasgow, Scotland

Hey Folks,

So I’ve had a recurring fault on my 2001 P38 Westminster with the 2.5 Diesel engine (autobox). The fault had been occurring about once every 2 months until recently when it has started happening almost daily.

Essentially what happens is that any time up to 20mins from startup (usually sooner) a series of faults occur at the same time.

The chain of events usually follows this sequence:

• “GEARBOX FAULT” displayed in message centre.

• “ALTERNATOR FAULT” displayed in message centre.

• EAS light on gauge cluster illuminated and all 4 EAS position lights stay on solid.

• Engine RPM gauge drops to 0.

• Engine revs erratically for a period up to 20 seconds with limited response to throttle.

• Rev counter comes back to life and EAS returns to normal.

• Gearbox becomes locked in 3rd gear at all speeds until engine has been turned off and back on again.

From the research I’ve done so far I know of a few possible causes for this peculiar behaviour including a weak battery, failing alternator or corroded ground straps. Replacing the battery with a beefy new Yuasa Black Series (tested multiple times and known to be good) hasn’t solved the issue. Nor does the fault appear to be as a result of a bad alternator (this was replaced for a new & genuine part which also didn’t solve the issue (voltage at alternator @2kRPM 14.4V with no drop to battery)). I’ve checked most of the ground straps with the ol’ multimeter and they all seem good (some new straps on the way nonetheless).

I was just wondering if anyone has had the same issue and found it to be caused by anything other than battery/alternator/ground wires, or if anyone might be able to shed some light on the issue.

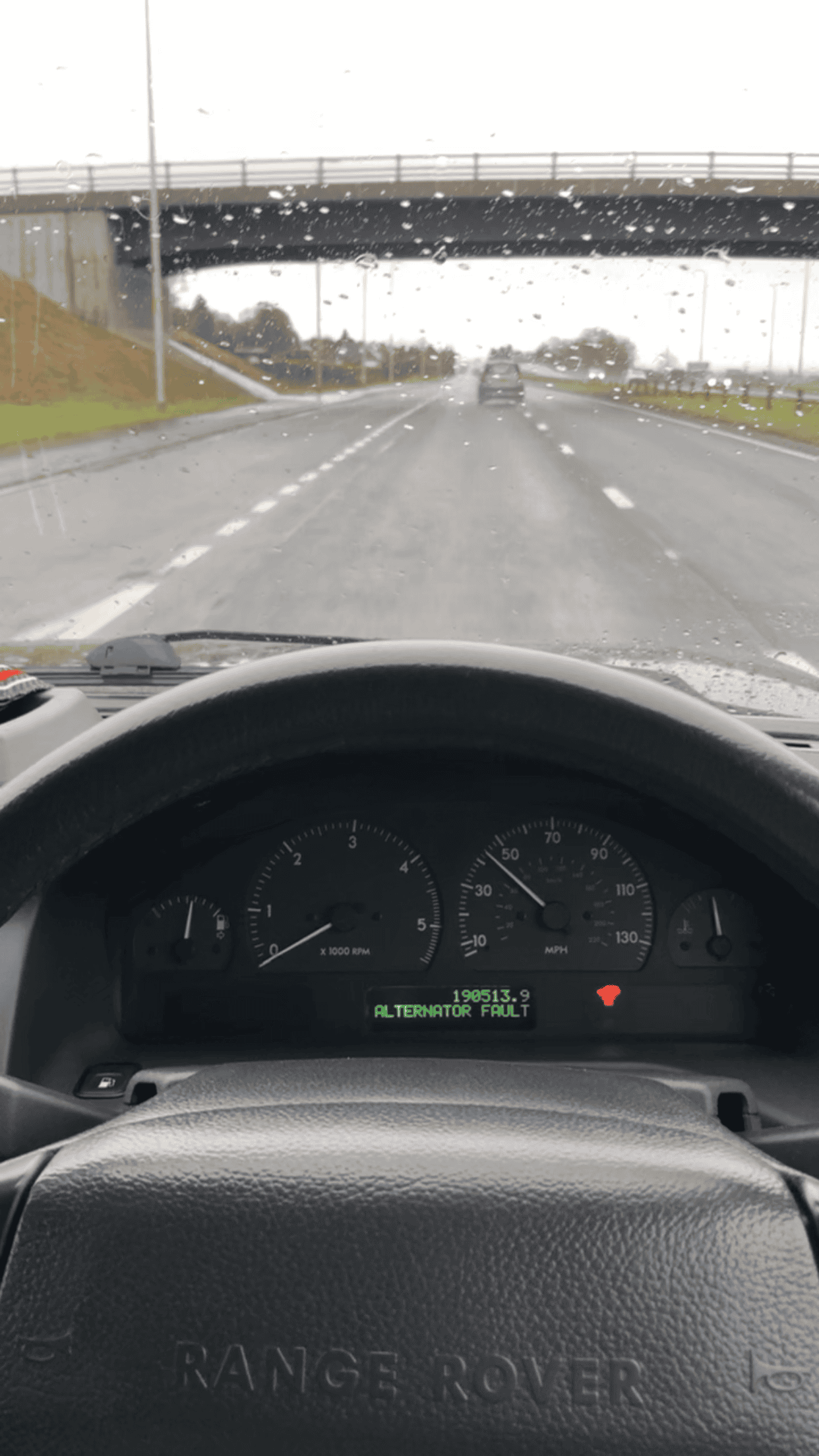

I’ve attached a pic

(hopefully) which shows the fault during driving ( albeit after some of the the messages had cleared).

(hopefully) which shows the fault during driving ( albeit after some of the the messages had cleared).

Thanks in advance!

Sandy.

So I’ve had a recurring fault on my 2001 P38 Westminster with the 2.5 Diesel engine (autobox). The fault had been occurring about once every 2 months until recently when it has started happening almost daily.

Essentially what happens is that any time up to 20mins from startup (usually sooner) a series of faults occur at the same time.

The chain of events usually follows this sequence:

• “GEARBOX FAULT” displayed in message centre.

• “ALTERNATOR FAULT” displayed in message centre.

• EAS light on gauge cluster illuminated and all 4 EAS position lights stay on solid.

• Engine RPM gauge drops to 0.

• Engine revs erratically for a period up to 20 seconds with limited response to throttle.

• Rev counter comes back to life and EAS returns to normal.

• Gearbox becomes locked in 3rd gear at all speeds until engine has been turned off and back on again.

From the research I’ve done so far I know of a few possible causes for this peculiar behaviour including a weak battery, failing alternator or corroded ground straps. Replacing the battery with a beefy new Yuasa Black Series (tested multiple times and known to be good) hasn’t solved the issue. Nor does the fault appear to be as a result of a bad alternator (this was replaced for a new & genuine part which also didn’t solve the issue (voltage at alternator @2kRPM 14.4V with no drop to battery)). I’ve checked most of the ground straps with the ol’ multimeter and they all seem good (some new straps on the way nonetheless).

I was just wondering if anyone has had the same issue and found it to be caused by anything other than battery/alternator/ground wires, or if anyone might be able to shed some light on the issue.

I’ve attached a pic

Thanks in advance!

Sandy.