Hi,

just rebuilt my 1999, 1.8 petrol Freelander (head gasket issue).

Engine won't start after the rebuild. Here's a brief list to what I did:

- Skimmed the cylinder block (sent it to a machine shop).

- Installed NEW cylinder head (brand is TopLine).

- Installed new: valves (plus springs and caps), MLS gasket, reinforced head screws, water pump, thermostat, belts etc etc.

- Did the screw patterns/torques by the manual.

- Timed the cam belt and tensed it (it's still timed).

- Note: I didn't lap my new valves on the new head because the guy from the shop told me I don't need to, since both head and valves are new.

After failing to start the engine:

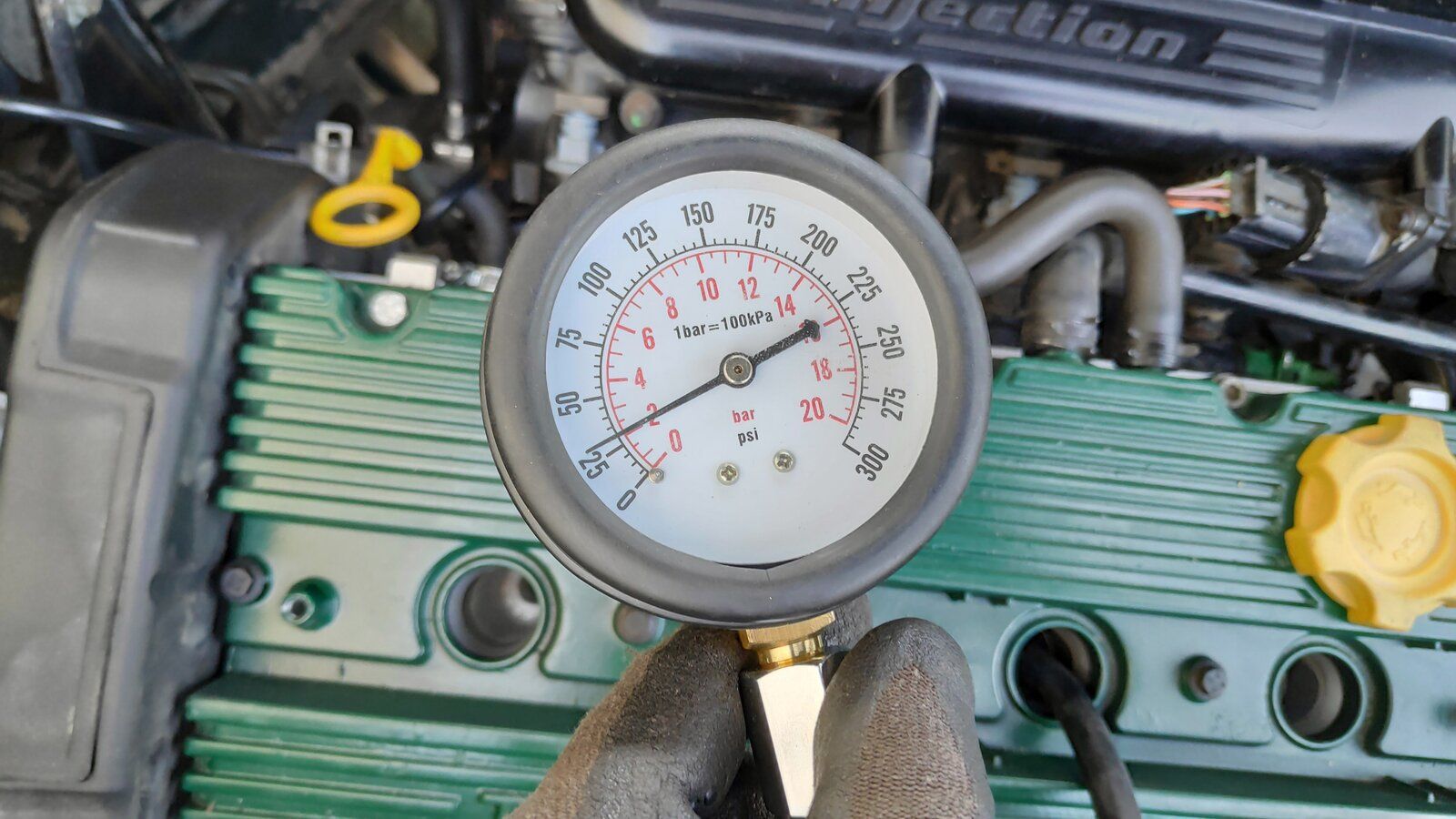

- I did a pressure test. Readings on cylinders 1-2-3-4 were very low, 30-25-25-30 psi (about 2 bars).

- I checked my pressure test kit on my other car, it read 175psi (12 bar) to all 4 cylinders, so those 25psi readings seem correct.

- Checked the timing belt, camshaft gears, crankshaft gear. Everything looked totally fine, all gears aligned to their marks.

Any help is appreciated.

just rebuilt my 1999, 1.8 petrol Freelander (head gasket issue).

Engine won't start after the rebuild. Here's a brief list to what I did:

- Skimmed the cylinder block (sent it to a machine shop).

- Installed NEW cylinder head (brand is TopLine).

- Installed new: valves (plus springs and caps), MLS gasket, reinforced head screws, water pump, thermostat, belts etc etc.

- Did the screw patterns/torques by the manual.

- Timed the cam belt and tensed it (it's still timed).

- Note: I didn't lap my new valves on the new head because the guy from the shop told me I don't need to, since both head and valves are new.

After failing to start the engine:

- I did a pressure test. Readings on cylinders 1-2-3-4 were very low, 30-25-25-30 psi (about 2 bars).

- I checked my pressure test kit on my other car, it read 175psi (12 bar) to all 4 cylinders, so those 25psi readings seem correct.

- Checked the timing belt, camshaft gears, crankshaft gear. Everything looked totally fine, all gears aligned to their marks.

Any help is appreciated.