Hi guys - quick question on a KV6 timing marks on the crank pulley

I have a KV6 here with a busted belt, so heads have been rebuilt and now it is fitting time - but following the manual brings questions (safe place does not line up with pin hole etc.) and the information I have gathered here is great - thanks to Hippos photos

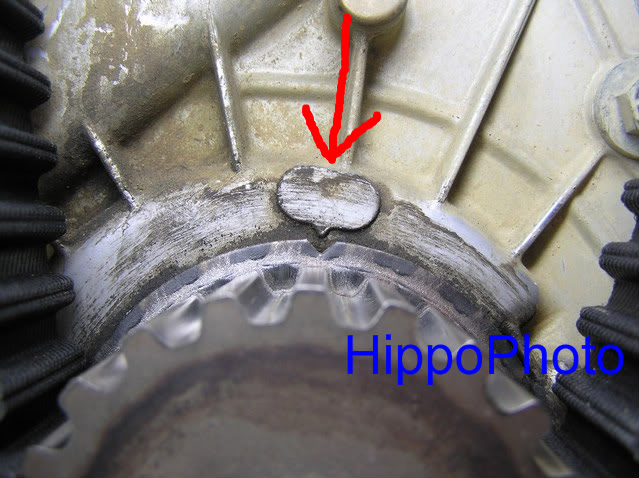

However - when I put the timing pin in and compare what I see to Hippos pics - it looks like my bottom pulley has the marks in the wrong place.

This is a US spec Auto and I can feel the timing pin go in the flexplate but this is the odd thing - the V grove on the rear shield points to the root of the tooth and Hippos pic looks like the V points to the top of the tooth

I have spent a long time on this motor and cannot risk it going wrong again!

I have not removed the front pulley to see if there is key damage, but it feels ok

So why will the pin go in and not line up?

Mike Canada

I have a KV6 here with a busted belt, so heads have been rebuilt and now it is fitting time - but following the manual brings questions (safe place does not line up with pin hole etc.) and the information I have gathered here is great - thanks to Hippos photos

However - when I put the timing pin in and compare what I see to Hippos pics - it looks like my bottom pulley has the marks in the wrong place.

This is a US spec Auto and I can feel the timing pin go in the flexplate but this is the odd thing - the V grove on the rear shield points to the root of the tooth and Hippos pic looks like the V points to the top of the tooth

I have spent a long time on this motor and cannot risk it going wrong again!

I have not removed the front pulley to see if there is key damage, but it feels ok

So why will the pin go in and not line up?

Mike Canada