htr

Well-Known Member

- Posts

- 1,563

- Location

- Central Otago, Southern New Zealand

For those who remember this is about my winter project from last year!

Yesterday I got that head back from the engineers They replaced some valve seats and checked and 'trimmed' the valve stem heights. It just requires a light clean, reassembly and it should be good to go. We talked about cleaning and testing hydraulic lifters. I've cleaned my set and some were corroded on the crown when I acquired the head so I discarded those ones [3]. I've got spare sets from other dismantled heads so I picked 3.

They replaced some valve seats and checked and 'trimmed' the valve stem heights. It just requires a light clean, reassembly and it should be good to go. We talked about cleaning and testing hydraulic lifters. I've cleaned my set and some were corroded on the crown when I acquired the head so I discarded those ones [3]. I've got spare sets from other dismantled heads so I picked 3.

The ones I chose came out of an overheated head. I felt that the springs inside the valve body of the lifters were softer that the good head so I swapped the springs over in the 'socket & plunger' assemblies. I noticed that the body of the replacement lifters has some scoring and blackening but otherwise appeared OK. My engineer suggested that along with dismantling & cleaning the lifters I should check their operation before installing and told me how to do that.

Reconsidering my choice of replacement lifter I was wondering if there was an advantage in using the set of lifters from my VVC head: the head itself is soft, 8 or so on the Brinell scale, as well as dismantled, so the lifters are right at hand. I know that they are the same diameter...

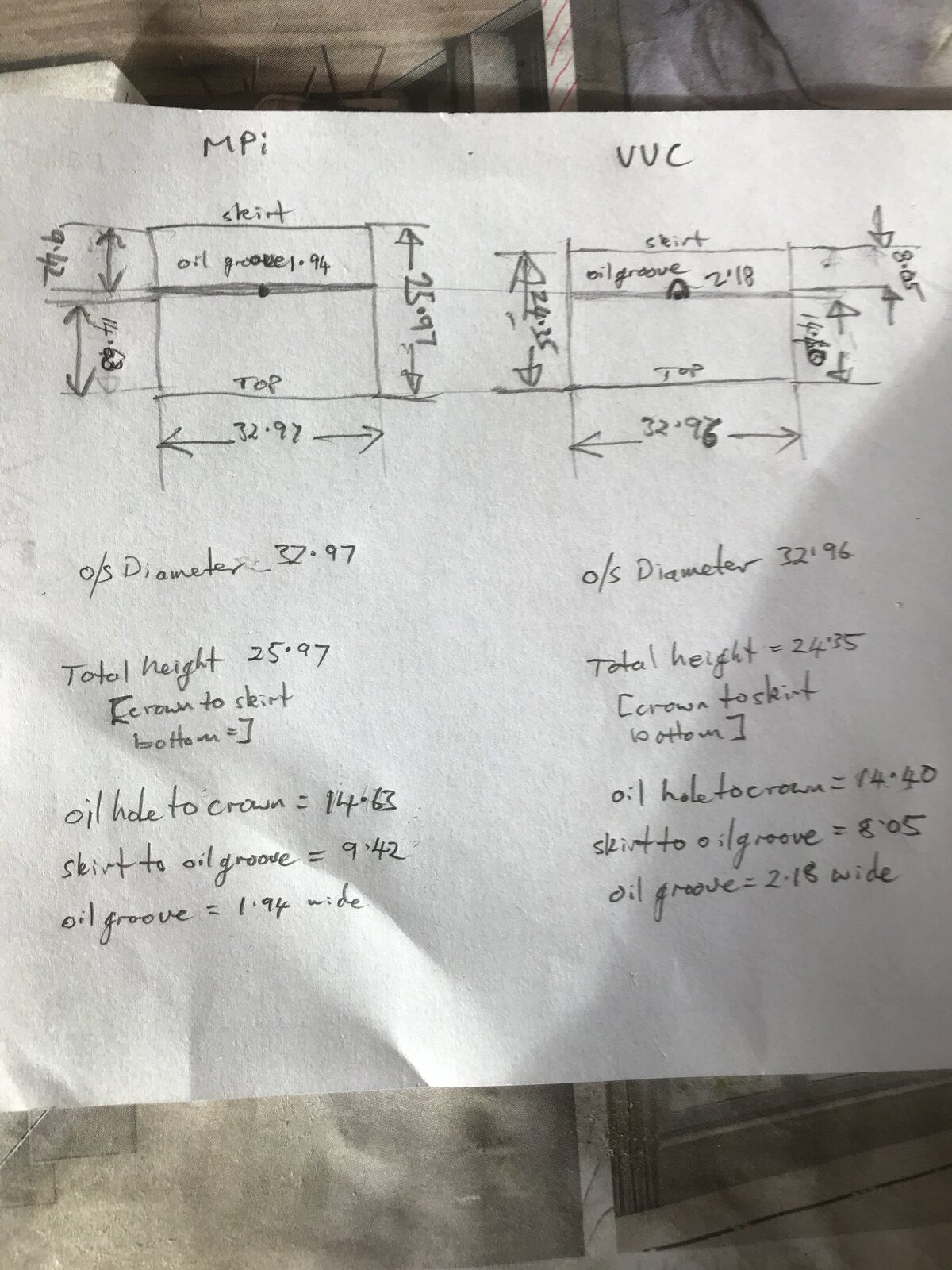

I've measured both lifters as best I can with my digital callipers. The VVC ones are about 1.6mm shorter than the MPi ones - see my sketch below.

The only thing I can think of is that it would possibly be a good idea as in the not to distant future I want to fit that VVC exhaust cam as my inlet cam. Those lifters are the correct ones for that cam.

What's the thinking, ok to swap over? Any problems you can see?

Yesterday I got that head back from the engineers

The ones I chose came out of an overheated head. I felt that the springs inside the valve body of the lifters were softer that the good head so I swapped the springs over in the 'socket & plunger' assemblies. I noticed that the body of the replacement lifters has some scoring and blackening but otherwise appeared OK. My engineer suggested that along with dismantling & cleaning the lifters I should check their operation before installing and told me how to do that.

Reconsidering my choice of replacement lifter I was wondering if there was an advantage in using the set of lifters from my VVC head: the head itself is soft, 8 or so on the Brinell scale, as well as dismantled, so the lifters are right at hand. I know that they are the same diameter...

I've measured both lifters as best I can with my digital callipers. The VVC ones are about 1.6mm shorter than the MPi ones - see my sketch below.

The only thing I can think of is that it would possibly be a good idea as in the not to distant future I want to fit that VVC exhaust cam as my inlet cam. Those lifters are the correct ones for that cam.

What's the thinking, ok to swap over? Any problems you can see?