Alibro

Well-Known Member

- Posts

- 7,409

- Location

- Northern Ireland

So you want to fit a lift kit,

DON'T DO IT YOU PLONKER!

Since you're determined to ignore my advice read on, but don't say you weren't warned!

Here are my pearls of wisdom/stupidity/experience (delete as appropriate)

Disclaimer. This is how I did it, I don't suggest it is the correct method or how you should do it. I take no responsibility for death or injury that may occur to you should you copy what I did.

First unless you really really REALLY need that extra 10mm then don't bother. Buy the 40mm kit instead and you will still need to cut some metal but not (so I'm told) the chassis rail. Whatever you do read the next bit about swapping the steering arms before you start.

The Fronts

Tools required

Long breaker bar

Hex socket set. (don't even think about doing it with a 12 point set)

Torque wrench

Big hammer, preferably ball pein.

Grinder

5mm Good quality allan key

Spanner set

Ball joint splitter

Spare parts required (probably)

Track rod ends

Drop links

1. Jack the car up and remove both front wheels

2. Turn the wheel full lock both ways and measure down 55mm from the track rod end bolts when at their lowest point then mark where you need to cut.

3. Sit back and stare in disbelief that you need to cut quite so much, think about it for a while then weep a little at your stupidity.

Passenger side.

4. Remove the clip holding the brake line to the strut and the abs cable.

5. Remove the track rod end nut and bash it out. Some people have success bashing the end of the arm beside the TRE so that the shock releases it but I've never found it to work.

TOP TIP, Put a sledge hammer or similar heavy lump of metal on the arm beside the TRE so that when you bash the bolt you've half a chance of getting it out without damaging the TRE. It helps prevent the arm flexing every time you bash with the hammer, If you're very lucky you won't damage the TRE but as you'll probably need a ball joint splitter don't bet on it.

6. Remove one end of the drop link. (doesn't matter which)

7. Remove the two big bolts at the bottom of the strut which will free up the wheel hub.

Drivers side

8. Disconnect the battery.

9. Open the fuse box and remove the three nuts holding it and the bolt holding the electrical connection and pull the fuse box out of the way.

10. On the TD4 you have another bolt to remove as a sensor (or something) is in the way

11. Pull out the plastic clip holding the two fuel lines to the chassis arm and push them out of the way.

11. Remove the plastic cover and the three bolts on the turret strut then the strut should drop out fairly easily.

12. Bolt the new lift kit onto the strut and set it to one side.

13. Cut out the metal facing you that you marked earlier while trying not to cut too far across the chassis rail. Pay more attention to the forward edge as that is where the bolt on the TRE will catch when on full lock.

14. Take your big hammer and start bashing the chassis rail down to the new level. It needs to be fairly level from your new edge to at least half way across the width of the chassis rail.

15. Once you've bashed the Bejesus out of the chassis rail and are happy it is low enough, then refit the strut and the bottom bolt but not the top one and don't tighten up the TRE. A jack under the brake disk will help getting it in position.

16. Fit the new top camber bolt with the camber pushing the top of the strut in. I had to cut the tab off my camber bolt washer as it fouled the edge of the strut.

17. Push the TRE into it's hole with a gentle tap from a hammer then take the nut from the old bolt and and use it as a spacer on the TRE and screw the TRE nut on finger tight.

18. Turn the wheel to full lock and marvel at how you got the cut out completely wrong. This is why the TRE bolt is in finger tight, remove it and tie the TRE up out of the way while you start bashing the beggar again with a hammer.

19. Repeat 18 multiple times until you have full lock.

20. Repeat on the other side, this time you need to move the coolant header tank out of the way to get the top strut nuts off.

21. I don't know how important it is but I plan to weld the chassis rail before painting.

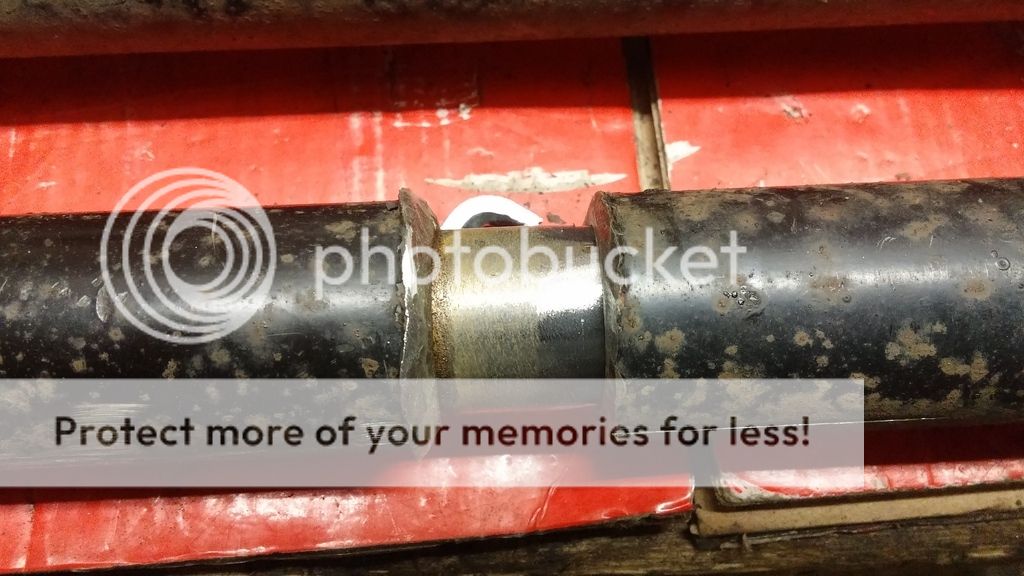

This photo gives you a good idea how far you need to cut down if you look at the position of the missing plastic rivet. Initially I didn't cut down far enough and gave myself a load of extra work, you need to turn the wheel to full lock, then mark down 50mm to see what needs cutting out.

******* Since writing this DieselDo suggested you can lessen the cutting required by swapping the steering arms. This will leave locking bolts on the track rod ends at the rear instead of the front which would help a lot. Also you can grind off a knob on the TRE to help a little more. This will help reduce the hammering and cutting a little but only if you do it before fitting the lift kit. I had already got the chassis arms adjusted for the TRE's before swapping the arms and now need to make more adjustments as the bolts now foul in a different spot.

OK, a quick update on how to swap the steering arms if you decide to do that. Note this was done on a TD4 with terrible access to the steering arm bolts. I did it from above but others have suggested it can be done through the wheel arch.

Steering Arms

Tools required

14mm spanner. If you have the correct torx socket and enough space to get at it then life will be much easier for you.

Short(ish) length of pipe that fits over the spanner

Normal tools to remove track rod ends.

Loctite

1. Turn steering to move the rack to a point where you can get access to it.

2. Reach into the back of the engine bay and fit your 14mm spanner over the torx bolts, put the pipe over the spanner and start the process of loosening the bolt a 1/4 turn at a time.

3. Repeat many many times. No it doesn't loosen up or get any easier as it is held in with locktite.

4. Loosen both bolts at the same time and remove.

5. Remove track rod ends as described below. Take them to your grinder and carefully remove the nodule beside the bolt.

Now would be a great time to free up the tracking adjustment lock nuts as you will need your tracking reset anyway. If yours are like mine were they get pretty seized and the guys at Kwiktit or wherever will probably chew up your lock nuts for you.

6. Swap the arms around and hesitate for a second as you see the TRE's are now upside down. Then laugh at your stupidity and remember they are screwed on and can be easily turned.

7. Using loctite refit the arms to the steering rack and tighten them up. I found the first one easy to get the bolt started but the second was a right pig. I found it helped to have the first one fairly tight.

Refit the TRE temporarily as described below and follow procedure for measuring, cutting and hammering.

The Rears

The rears are easier then the fronts but not without their issues. The flexi brake hose goes from the chassis to the strut then a hard connection goes from the strut to the wheel hub. This means that for you to remove the strut you need to disconnect the flexi hose either at the chassis or the strut. Either way you are in for trouble as the solid pipe will probably be welded to the nut so that it twists as you loosen it. I'd advise you disconnect at the strut end because it is a whole lot easier to replace the short pipe than the long one which goes towards the front of the car. I had to replace both the flexi hose and the solid pipe on the passenger side as the main brake pipe was leaking before I touched it.

So here goes.

Tools required.

Long breaker bar

Hex Socket set

Spanners

Brake pipe crimping tool

11mm brake pipe spanner

Spare parts required

Brake pipe

Brake pipe unions

Or just buy the brake pipes ready made.

1. Remove plastic panels in the boot which cover rear strut turrets.

2. Jack up rear of car and remove wheels

3. Remove the nuts from the two bolts at the bottom of the strut but don't tap them out yet.

4. Release the ABS cable and try to loosen brake pipe union where it joins the flexi pipe at the strut.

5. Realise the pipe is twisting with the union and brake fluid is now ****ing everywhere, swear, run and make up a new pipe the correct length and then carry on disconnecting the union and trashing the pipe.

6. Now with a bowl collecting the dripping brake fluid (unless you have a brake pipe crimp but I don't like them as they can damage the pipes or had the sense to cut the pipe which isn't going to survive anyway and fold it over) release the two large bolts.

7. Remove the three turret nuts and the strut should fall out fairly easily.

8. bolt on the 50mm lift kit and refit. A bit of pushing and pulling is required but a jack under the hub will help get it into position.

9. Reconnect the brake pipe and refit ABS cable

10. Bleed your brakes

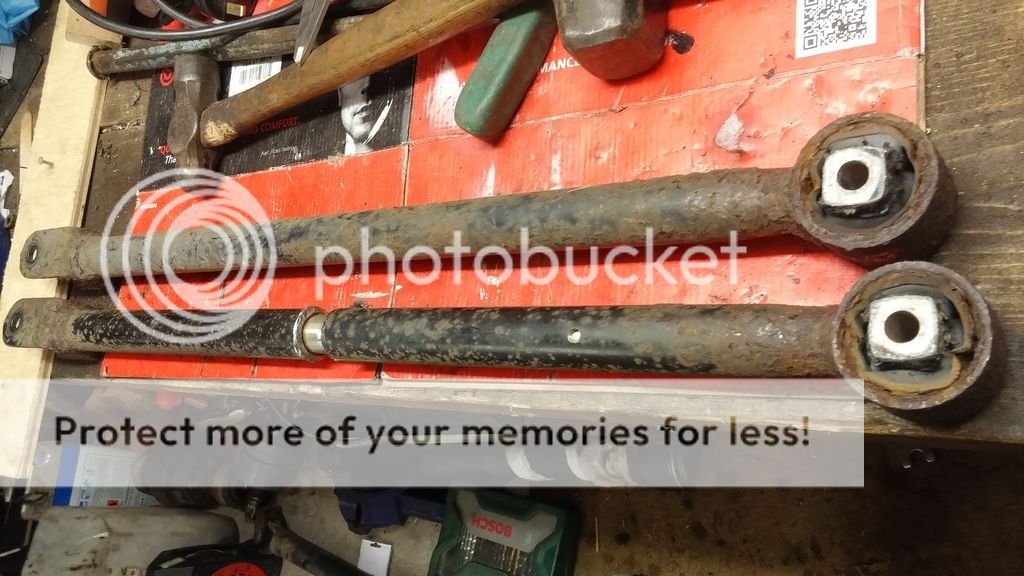

Top tip. Make these up to stop the dripping brake fluid if you're like me and don't like clamping the flexy pipes.

They are male and female brake unions on a short length of pipe with the ends crimped over.

DON'T DO IT YOU PLONKER!

Since you're determined to ignore my advice read on, but don't say you weren't warned!

Here are my pearls of wisdom/stupidity/experience (delete as appropriate)

Disclaimer. This is how I did it, I don't suggest it is the correct method or how you should do it. I take no responsibility for death or injury that may occur to you should you copy what I did.

First unless you really really REALLY need that extra 10mm then don't bother. Buy the 40mm kit instead and you will still need to cut some metal but not (so I'm told) the chassis rail. Whatever you do read the next bit about swapping the steering arms before you start.

The Fronts

Tools required

Long breaker bar

Hex socket set. (don't even think about doing it with a 12 point set)

Torque wrench

Big hammer, preferably ball pein.

Grinder

5mm Good quality allan key

Spanner set

Ball joint splitter

Spare parts required (probably)

Track rod ends

Drop links

1. Jack the car up and remove both front wheels

2. Turn the wheel full lock both ways and measure down 55mm from the track rod end bolts when at their lowest point then mark where you need to cut.

3. Sit back and stare in disbelief that you need to cut quite so much, think about it for a while then weep a little at your stupidity.

Passenger side.

4. Remove the clip holding the brake line to the strut and the abs cable.

5. Remove the track rod end nut and bash it out. Some people have success bashing the end of the arm beside the TRE so that the shock releases it but I've never found it to work.

TOP TIP, Put a sledge hammer or similar heavy lump of metal on the arm beside the TRE so that when you bash the bolt you've half a chance of getting it out without damaging the TRE. It helps prevent the arm flexing every time you bash with the hammer, If you're very lucky you won't damage the TRE but as you'll probably need a ball joint splitter don't bet on it.

6. Remove one end of the drop link. (doesn't matter which)

7. Remove the two big bolts at the bottom of the strut which will free up the wheel hub.

Drivers side

8. Disconnect the battery.

9. Open the fuse box and remove the three nuts holding it and the bolt holding the electrical connection and pull the fuse box out of the way.

10. On the TD4 you have another bolt to remove as a sensor (or something) is in the way

11. Pull out the plastic clip holding the two fuel lines to the chassis arm and push them out of the way.

11. Remove the plastic cover and the three bolts on the turret strut then the strut should drop out fairly easily.

12. Bolt the new lift kit onto the strut and set it to one side.

13. Cut out the metal facing you that you marked earlier while trying not to cut too far across the chassis rail. Pay more attention to the forward edge as that is where the bolt on the TRE will catch when on full lock.

14. Take your big hammer and start bashing the chassis rail down to the new level. It needs to be fairly level from your new edge to at least half way across the width of the chassis rail.

15. Once you've bashed the Bejesus out of the chassis rail and are happy it is low enough, then refit the strut and the bottom bolt but not the top one and don't tighten up the TRE. A jack under the brake disk will help getting it in position.

16. Fit the new top camber bolt with the camber pushing the top of the strut in. I had to cut the tab off my camber bolt washer as it fouled the edge of the strut.

17. Push the TRE into it's hole with a gentle tap from a hammer then take the nut from the old bolt and and use it as a spacer on the TRE and screw the TRE nut on finger tight.

18. Turn the wheel to full lock and marvel at how you got the cut out completely wrong. This is why the TRE bolt is in finger tight, remove it and tie the TRE up out of the way while you start bashing the beggar again with a hammer.

19. Repeat 18 multiple times until you have full lock.

20. Repeat on the other side, this time you need to move the coolant header tank out of the way to get the top strut nuts off.

21. I don't know how important it is but I plan to weld the chassis rail before painting.

This photo gives you a good idea how far you need to cut down if you look at the position of the missing plastic rivet. Initially I didn't cut down far enough and gave myself a load of extra work, you need to turn the wheel to full lock, then mark down 50mm to see what needs cutting out.

******* Since writing this DieselDo suggested you can lessen the cutting required by swapping the steering arms. This will leave locking bolts on the track rod ends at the rear instead of the front which would help a lot. Also you can grind off a knob on the TRE to help a little more. This will help reduce the hammering and cutting a little but only if you do it before fitting the lift kit. I had already got the chassis arms adjusted for the TRE's before swapping the arms and now need to make more adjustments as the bolts now foul in a different spot.

OK, a quick update on how to swap the steering arms if you decide to do that. Note this was done on a TD4 with terrible access to the steering arm bolts. I did it from above but others have suggested it can be done through the wheel arch.

Steering Arms

Tools required

14mm spanner. If you have the correct torx socket and enough space to get at it then life will be much easier for you.

Short(ish) length of pipe that fits over the spanner

Normal tools to remove track rod ends.

Loctite

1. Turn steering to move the rack to a point where you can get access to it.

2. Reach into the back of the engine bay and fit your 14mm spanner over the torx bolts, put the pipe over the spanner and start the process of loosening the bolt a 1/4 turn at a time.

3. Repeat many many times. No it doesn't loosen up or get any easier as it is held in with locktite.

4. Loosen both bolts at the same time and remove.

5. Remove track rod ends as described below. Take them to your grinder and carefully remove the nodule beside the bolt.

Now would be a great time to free up the tracking adjustment lock nuts as you will need your tracking reset anyway. If yours are like mine were they get pretty seized and the guys at Kwiktit or wherever will probably chew up your lock nuts for you.

6. Swap the arms around and hesitate for a second as you see the TRE's are now upside down. Then laugh at your stupidity and remember they are screwed on and can be easily turned.

7. Using loctite refit the arms to the steering rack and tighten them up. I found the first one easy to get the bolt started but the second was a right pig. I found it helped to have the first one fairly tight.

Refit the TRE temporarily as described below and follow procedure for measuring, cutting and hammering.

The Rears

The rears are easier then the fronts but not without their issues. The flexi brake hose goes from the chassis to the strut then a hard connection goes from the strut to the wheel hub. This means that for you to remove the strut you need to disconnect the flexi hose either at the chassis or the strut. Either way you are in for trouble as the solid pipe will probably be welded to the nut so that it twists as you loosen it. I'd advise you disconnect at the strut end because it is a whole lot easier to replace the short pipe than the long one which goes towards the front of the car. I had to replace both the flexi hose and the solid pipe on the passenger side as the main brake pipe was leaking before I touched it.

So here goes.

Tools required.

Long breaker bar

Hex Socket set

Spanners

Brake pipe crimping tool

11mm brake pipe spanner

Spare parts required

Brake pipe

Brake pipe unions

Or just buy the brake pipes ready made.

1. Remove plastic panels in the boot which cover rear strut turrets.

2. Jack up rear of car and remove wheels

3. Remove the nuts from the two bolts at the bottom of the strut but don't tap them out yet.

4. Release the ABS cable and try to loosen brake pipe union where it joins the flexi pipe at the strut.

5. Realise the pipe is twisting with the union and brake fluid is now ****ing everywhere, swear, run and make up a new pipe the correct length and then carry on disconnecting the union and trashing the pipe.

6. Now with a bowl collecting the dripping brake fluid (unless you have a brake pipe crimp but I don't like them as they can damage the pipes or had the sense to cut the pipe which isn't going to survive anyway and fold it over) release the two large bolts.

7. Remove the three turret nuts and the strut should fall out fairly easily.

8. bolt on the 50mm lift kit and refit. A bit of pushing and pulling is required but a jack under the hub will help get it into position.

9. Reconnect the brake pipe and refit ABS cable

10. Bleed your brakes

Top tip. Make these up to stop the dripping brake fluid if you're like me and don't like clamping the flexy pipes.

They are male and female brake unions on a short length of pipe with the ends crimped over.

Last edited: