Knut Eggum

Member

- Posts

- 11

- Location

- Norway

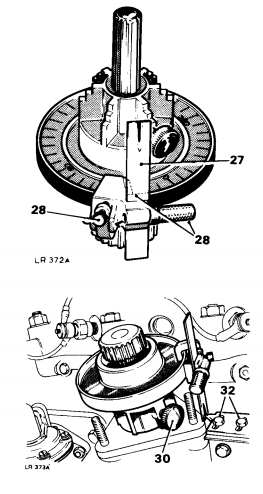

It is difficult and expensive to get a "Timing Gauge" for a 2.25 S3 diesel. There are several options, a used original 605863 or an MS67B, or a new from http://www.dingocroft.co.uk/acatalog/Engine_tools1-p2.html.

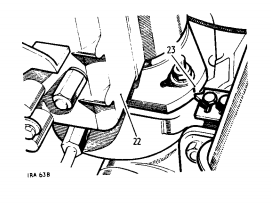

I want to make one myself. Is there anyone who knows exactly the angle between the wide teeth on the shaft for the distrbution pump and the pointer on the engine block?

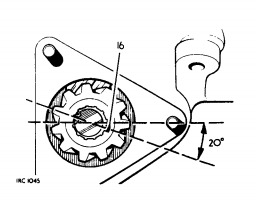

The service manual says you should set the flywheel to 13 degrees BTDC and use a timing gauge, 605863 or MS67B. The MS67B is to be set to 22 degrees.

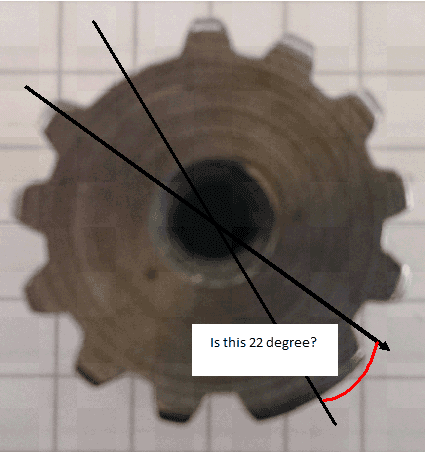

I have taken a picture of the shaft and draw two lines. I assume that the angle is 22 degree. Does anyone having a "Timing Gauge" confirm that I have thought correctly and the arrow on the figure match the pointer on the engine?

I want to make one myself. Is there anyone who knows exactly the angle between the wide teeth on the shaft for the distrbution pump and the pointer on the engine block?

The service manual says you should set the flywheel to 13 degrees BTDC and use a timing gauge, 605863 or MS67B. The MS67B is to be set to 22 degrees.

I have taken a picture of the shaft and draw two lines. I assume that the angle is 22 degree. Does anyone having a "Timing Gauge" confirm that I have thought correctly and the arrow on the figure match the pointer on the engine?