payydg

Well-Known Member

- Posts

- 3,932

- Location

- Aberdeenshire

I can even give you a full cutting plan from 8x4 sheets for the girls at BnQ

Now that is awesome. I'll message you some dimensions. Thanks dude

I can even give you a full cutting plan from 8x4 sheets for the girls at BnQ

These thum.....................................?????

Product Dimensions:510mm (20.1") L x 400mm (15.8") W x 230mm (9.1") H

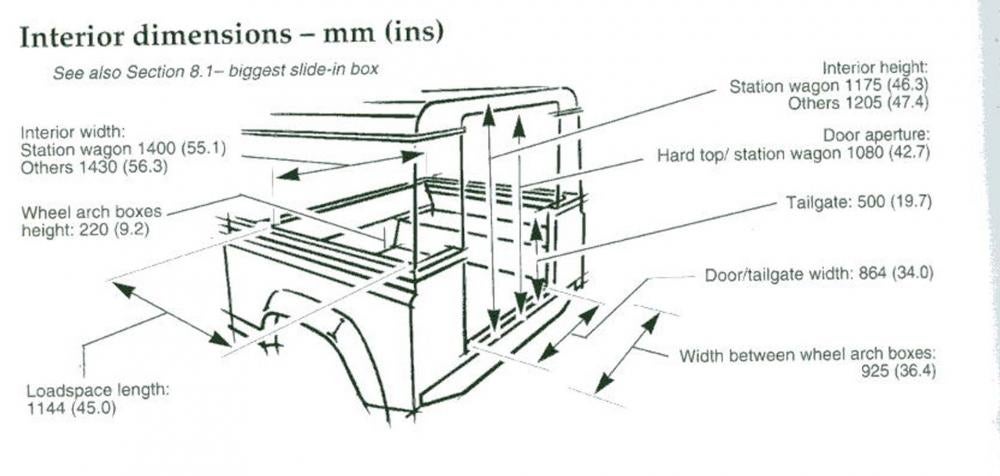

Biggest problem I had when doing my pull out drawers was the sheet of ply that sits between the arches (in my case 3/4 of the depth) wouldnt go in in one piece. So I had to split it down the center as below. You might be OK with a narrower shelf.I've got a couple of things (like a bulk head water tank) that change the dims a bit. That is a useful picture tho. Will PM you buddy tomorrow after work

Biggest problem I had when doing my pull out drawers was the sheet of ply that sits between the arches (in my case 3/4 of the depth) wouldnt go in in one piece. So I had to split it down the center as below. You might be OK with a narrower shelf.

View attachment 121454

You will get the full sheet in because its only as wide as the space between the arches. It wont go in flat coz the door is ever so slightly narrower but it will go in on the slant and lay flat. My shelf is as wide as the sides and wouldnt turn once in the back.

The only down side is getting all the wolf boxes out if you want one thats at the back. I have made drawers in mine that pull out all the way so the whole drawer is accessable. You could do the same with a simple pull out 'flat' unit that the boxes sit on. It all depends on the dimensions.

My Land Rover is a series so I am not positive the sizes are the same. The drawing I posted was meant to be a 90 so If you can throw a tape measure over yours to confirm the sizes are the same as the drawing I can give you some easy options on how to build the shelf for easy access.

Ang on a mo.

The wolf box is 510mm, x 2. 1020 ?

The available load space is 1000 long.

You might not get the door closed....................

Ere ye pest..................

Took weeks.

Well, half an hour on t'laptop

How did you get the timber in and turn it into position or isnt it a 90. Sounds a good idea.I've got almost identical design to what Bobsticle has come up with ( nice vid by the way! ), but I cut and laid my top sheet of ply sideways rather than length ways, I also have a narrow strip of ply (w: 50mm) across the wheel arches (almost on top of the rear bulkhead). The first sheet of ply is hinged to this and then the second sheet of ply is is hinged to the first. This way the whole lot can fold up and lay on the folded-down rear passenger seats, should I need to stick anytime bulky in the back.

I don't have a centre divider ( I don't have boxes, just loads of gardening tools underneath ) and 18mm ply holds up nicely.

I not making any bloody movies to demonstrate this, but I'll see if I can get a photo later, currently the rear is full of all manner of shite!

The sheets aren't the full width of the wheel arches, I've got some 2x1 (ish) baton on the arches, as you have, to increase the height underneath and then about an 8" gap between the sheet and the side panels of the Landy, this creates a handy space for some tool boxes, spare oil etc. I'll pop some photos of the mess a bit later!How did you get the timber in and turn it into position or isnt it a 90. Sounds a good idea.

I though you might have had a way of doing it I hadnt thought of.The sheets aren't the full width of the wheel arches, I've got some 2x1 (ish) baton on the arches, as you have, to increase the height underneath and then about an 8" gap between the sheet and the side panels of the Landy, this creates a handy space for some tool boxes, spare oil etc. I'll pop some photos of the mess a bit later!

What software did you create those designs on? Looks like SketchUp (pro)? I've wanted to be able to get to that stage of creativity, but I just don't spend enough time practicing!

Didn't realise it was for a 90, I've got a 110. Same principle I guess.

Just found the pics of mine being butchered.Hopefully the end product looks as good as that!

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!