Litch

Well-Known Member

- Posts

- 2,235

- Location

- Oxfordshire

Funny how some jobs just grow and grow!

Earlier in the year I decided to buy an exterior sun-visor for the 90, always wanted one but just never got around to doing it.

Bought said sun-visor from Cannon Services (Banbury) and popped into my local paintshop who does all my parts to get it colour matched. He said that it would be more cost effective if he painted some other bits at the same time so I decided this was the perfect time to get those new (all steel / galvanised) front doors and while I was at it, take off the rear tub and get that painted as well (some small spots of corrosion showing through).

With the tub stripped of all parts (capping, lights etc) the bits went away leaving me 7-10 days to give the rear chassis a clean-up while I had all that access.

At this point I should add that the vehicle is an ex-MOD 90 of 1986 vintage which has never been welded and I have owned it since release in 1999. I have always said that I am not going to weld another chassis (a S111 & 101FC showed me what fun that can be) and when rust sets in I would go for a galvanised replacement. Having already owned the vehicle for 20-years and carried out much work it is a keeper so I always look to the long term.

Well, I was rubbing down the underseal (black Waxoyl under-body, an excellent product which has served me well for decades) and found rust between the two plates that make up the bottom edge of the rear crossmember. This is probably not serious enough for any normal person to even start looking at a replacement crossmember but I am of the opinion that when rust is visible there is more hiding away beyond sight or poke from a screwdriver, thus it has set in motion a chain of events which will see me completing the undersealing and getting the vehicle back on the road in the next week or so but also starting to prepare the ground for a new chassis next spring (get through the winter first as the 90 is a godsend in the snow & ice).

Have already decided on a Richards chassis and along with this will be all the usual items that it makes sense to replace when carrying out such a major task (new wiring loom, brake-pipes, fuel-tank etc etc). Many major components have already been replaced with new over the years and even things like the suspension are relatively recent so will just be swopped straight across. Will be finishing the chassis in black so have plenty of time to settle on a suitable coating, I also make extensive use of SS fixings which is a boon when it comes to dismantling as most items come apart with ease (after being suitably lubricated on assembly of course). The new doors will be built up & fitted in the next few weeks so as many major items as possible can be moved from one chassis to the other.

The shopping list is already starting to grow and it looks like my 2-ton engine-crane is finally going to earn its living (I work alone so not only will it be carrying the engine & gearbox but will also lifting the fully built-up bulkhead and rear tub assemblies etc). I only have the one set of axles / wheels so one chassis will be mobile while the other is supported on axle-stands, will have to work out the best sequence to do the axle change as this work is going to pretty much block the driveway and make getting my bike out of the garage a bit difficult (Guzzi Stelvio which doesn't fit through narrow gaps very well). On the whole, the lack of space & access is going to be a bit of an issue as I am expecting the swop to take at least 2-3 months, one plus point though is that I am working under a carport which protects against most of the weather (horizontal rain excluded!).

This thread will probably die now but I will resurrect it next year when work begins!!!!

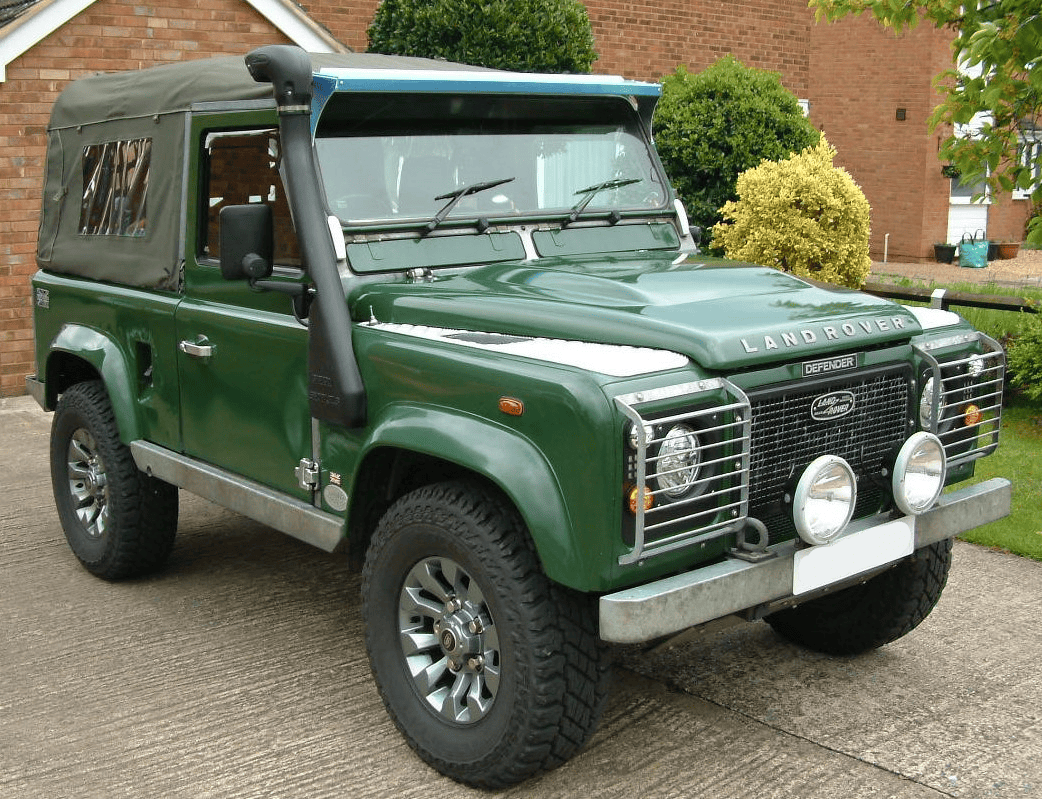

Un-painted sun-visor in position, what a lot of trouble it has caused!

Earlier in the year I decided to buy an exterior sun-visor for the 90, always wanted one but just never got around to doing it.

Bought said sun-visor from Cannon Services (Banbury) and popped into my local paintshop who does all my parts to get it colour matched. He said that it would be more cost effective if he painted some other bits at the same time so I decided this was the perfect time to get those new (all steel / galvanised) front doors and while I was at it, take off the rear tub and get that painted as well (some small spots of corrosion showing through).

With the tub stripped of all parts (capping, lights etc) the bits went away leaving me 7-10 days to give the rear chassis a clean-up while I had all that access.

At this point I should add that the vehicle is an ex-MOD 90 of 1986 vintage which has never been welded and I have owned it since release in 1999. I have always said that I am not going to weld another chassis (a S111 & 101FC showed me what fun that can be) and when rust sets in I would go for a galvanised replacement. Having already owned the vehicle for 20-years and carried out much work it is a keeper so I always look to the long term.

Well, I was rubbing down the underseal (black Waxoyl under-body, an excellent product which has served me well for decades) and found rust between the two plates that make up the bottom edge of the rear crossmember. This is probably not serious enough for any normal person to even start looking at a replacement crossmember but I am of the opinion that when rust is visible there is more hiding away beyond sight or poke from a screwdriver, thus it has set in motion a chain of events which will see me completing the undersealing and getting the vehicle back on the road in the next week or so but also starting to prepare the ground for a new chassis next spring (get through the winter first as the 90 is a godsend in the snow & ice).

Have already decided on a Richards chassis and along with this will be all the usual items that it makes sense to replace when carrying out such a major task (new wiring loom, brake-pipes, fuel-tank etc etc). Many major components have already been replaced with new over the years and even things like the suspension are relatively recent so will just be swopped straight across. Will be finishing the chassis in black so have plenty of time to settle on a suitable coating, I also make extensive use of SS fixings which is a boon when it comes to dismantling as most items come apart with ease (after being suitably lubricated on assembly of course). The new doors will be built up & fitted in the next few weeks so as many major items as possible can be moved from one chassis to the other.

The shopping list is already starting to grow and it looks like my 2-ton engine-crane is finally going to earn its living (I work alone so not only will it be carrying the engine & gearbox but will also lifting the fully built-up bulkhead and rear tub assemblies etc). I only have the one set of axles / wheels so one chassis will be mobile while the other is supported on axle-stands, will have to work out the best sequence to do the axle change as this work is going to pretty much block the driveway and make getting my bike out of the garage a bit difficult (Guzzi Stelvio which doesn't fit through narrow gaps very well). On the whole, the lack of space & access is going to be a bit of an issue as I am expecting the swop to take at least 2-3 months, one plus point though is that I am working under a carport which protects against most of the weather (horizontal rain excluded!).

This thread will probably die now but I will resurrect it next year when work begins!!!!

Un-painted sun-visor in position, what a lot of trouble it has caused!