mikerajjers

Well-Known Member

- Posts

- 1,467

- Location

- Bedford UK or Trnava SK

I fitted parabolic springs and gas shocks all-round on my S3 109 FFR about 1 month ago so want to contribute with a short write up.

Quick points before we start:

1 - I have no mechanical background other that youtube, some manuals, selection of ordinary tools and common sense - if I could do it anybody can!!! Don't be afraid and don't bother paying somebody to do it as they won't care about your vehicle as much as you do!

2 - I fitted Rocky Mountain springs and gas shocks that came as a set with all the shackles, bolts, etc. For a 109 their website recommends 3 leaf for the rear, I have fitted 2 leaf and they are perfect when lightly loaded...unless you carry LOADS of weight I wouldn't bother with the 3 leaf as you will get greater problems with the rear prop shaft rubbing - see later.

3. tools required - standard Halfords tool set + jacks, copper grease, angle grinder (depending how rusted your bolts are), breaker bars, degreaser/cleaning stuff-a lot of it!

Lift and support your Landy, I used axle stands beneath the chassis, remember you can't support the axles as you need to move these around a little.

Remove the old springs, I recommend removing the U-bolts first, then find a way to support the axle so that it doesn't drop down when you remove the spring. Clean bits up and paint if you want to. To remove the springs, un-tighten and remove bolts at front and rear - you don't need to keep the old shackle as the kit comes with new ones. I used some penetrating oil, once a blow torch to heat one bolts, but wouldn't budge and had to cut it out with the angle grinder. All other bolts were ok and just required elbow grease.

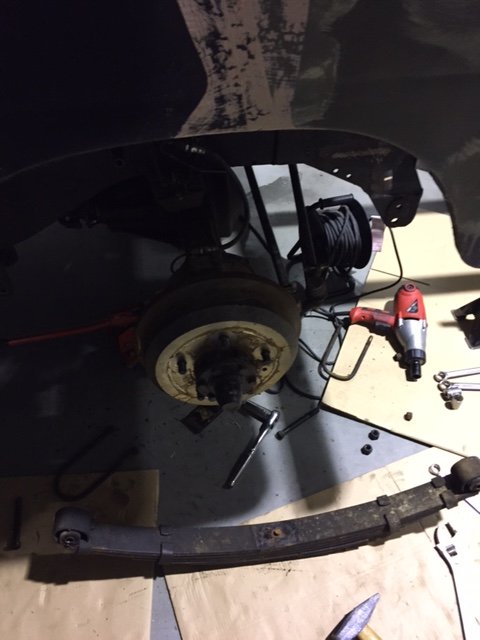

Fitting new springs is just the reverse process, fit the new parabolics, secure with shackles but don't tighten, just enough so that it won't fall apart. Then you can release the supports that were holding your axles and line up the hole in the axle with the protruison on the spring. You may need to compress or extend the springs a little to get them to line up...as you can see I used a bottle jack to help me. It is obvious what needs to be done when you get going.

Once you've got it lines up you can fit and tighten the U bolts. There is one longer U-bolt needed for the diff side, other than that they are all the same. Above I'm just about to fit U bolts

A cup of tea is vital...do not overlook this point!!! Does not have to be one with Pikachu!

U bolts fitted. I also took the opportunity to clean up my VIN stamp and spray with primer so that I minimise corrosion.

Quick points before we start:

1 - I have no mechanical background other that youtube, some manuals, selection of ordinary tools and common sense - if I could do it anybody can!!! Don't be afraid and don't bother paying somebody to do it as they won't care about your vehicle as much as you do!

2 - I fitted Rocky Mountain springs and gas shocks that came as a set with all the shackles, bolts, etc. For a 109 their website recommends 3 leaf for the rear, I have fitted 2 leaf and they are perfect when lightly loaded...unless you carry LOADS of weight I wouldn't bother with the 3 leaf as you will get greater problems with the rear prop shaft rubbing - see later.

3. tools required - standard Halfords tool set + jacks, copper grease, angle grinder (depending how rusted your bolts are), breaker bars, degreaser/cleaning stuff-a lot of it!

Lift and support your Landy, I used axle stands beneath the chassis, remember you can't support the axles as you need to move these around a little.

Remove the old springs, I recommend removing the U-bolts first, then find a way to support the axle so that it doesn't drop down when you remove the spring. Clean bits up and paint if you want to. To remove the springs, un-tighten and remove bolts at front and rear - you don't need to keep the old shackle as the kit comes with new ones. I used some penetrating oil, once a blow torch to heat one bolts, but wouldn't budge and had to cut it out with the angle grinder. All other bolts were ok and just required elbow grease.

Fitting new springs is just the reverse process, fit the new parabolics, secure with shackles but don't tighten, just enough so that it won't fall apart. Then you can release the supports that were holding your axles and line up the hole in the axle with the protruison on the spring. You may need to compress or extend the springs a little to get them to line up...as you can see I used a bottle jack to help me. It is obvious what needs to be done when you get going.

Once you've got it lines up you can fit and tighten the U bolts. There is one longer U-bolt needed for the diff side, other than that they are all the same. Above I'm just about to fit U bolts

A cup of tea is vital...do not overlook this point!!! Does not have to be one with Pikachu!

U bolts fitted. I also took the opportunity to clean up my VIN stamp and spray with primer so that I minimise corrosion.