Dan_Trials

Well-Known Member

- Posts

- 2,546

Today removed pretty much all I need to in order to weld it up. It is not as bad as I expected under the carpet.

This is yukky mold on the carpet:

Driver's seat removed:

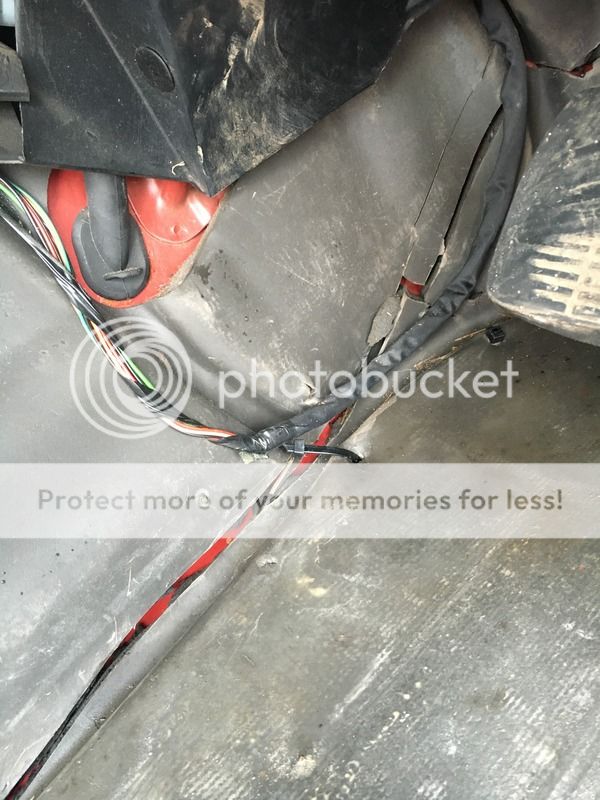

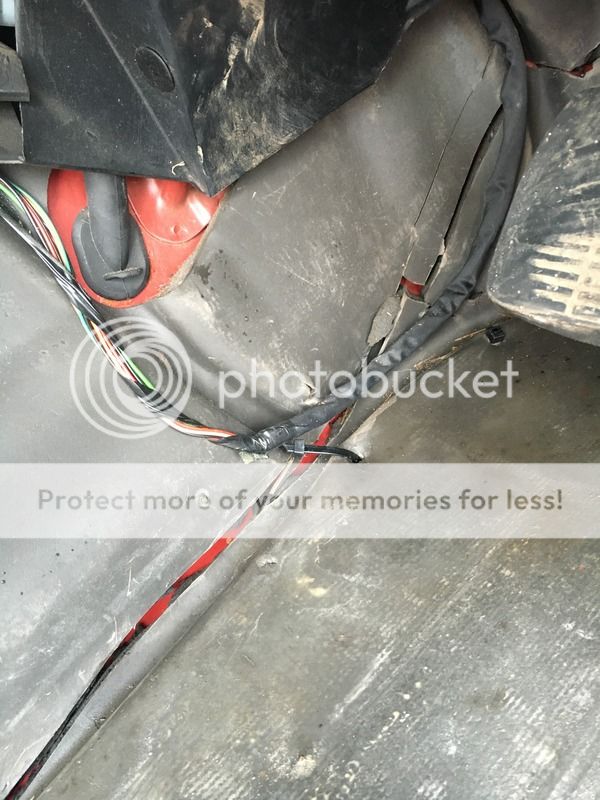

Some one has been at it already:

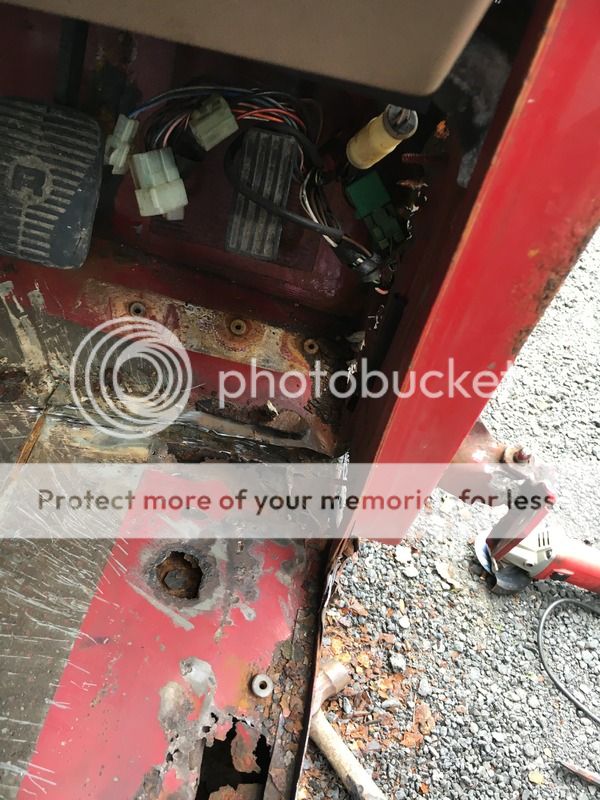

Bits of my Landy are doing a wee:

I have no idea what this is supposed to be:

More of it:

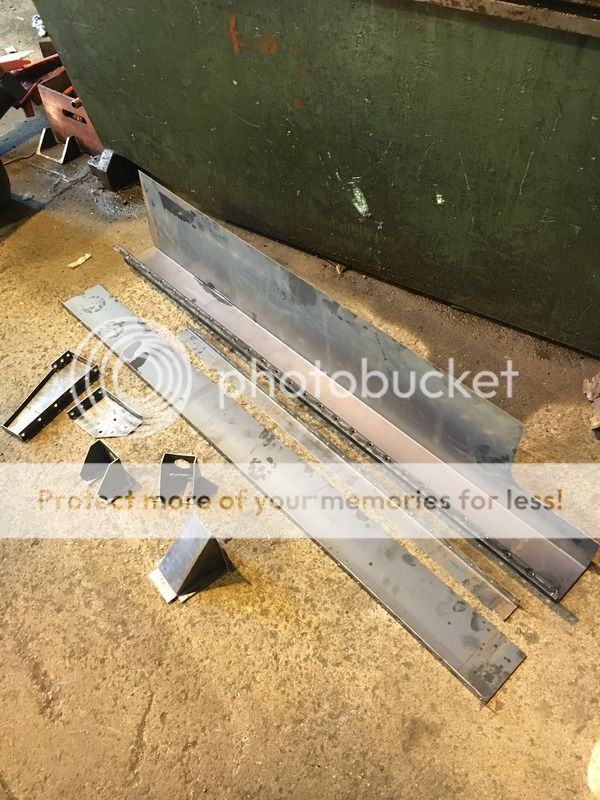

Ready to start at it with angle grinder:

This is yukky mold on the carpet:

Driver's seat removed:

Some one has been at it already:

Bits of my Landy are doing a wee:

I have no idea what this is supposed to be:

More of it:

Ready to start at it with angle grinder: