So today, my pal showed up and helped.

This happened with the bonnet still attached

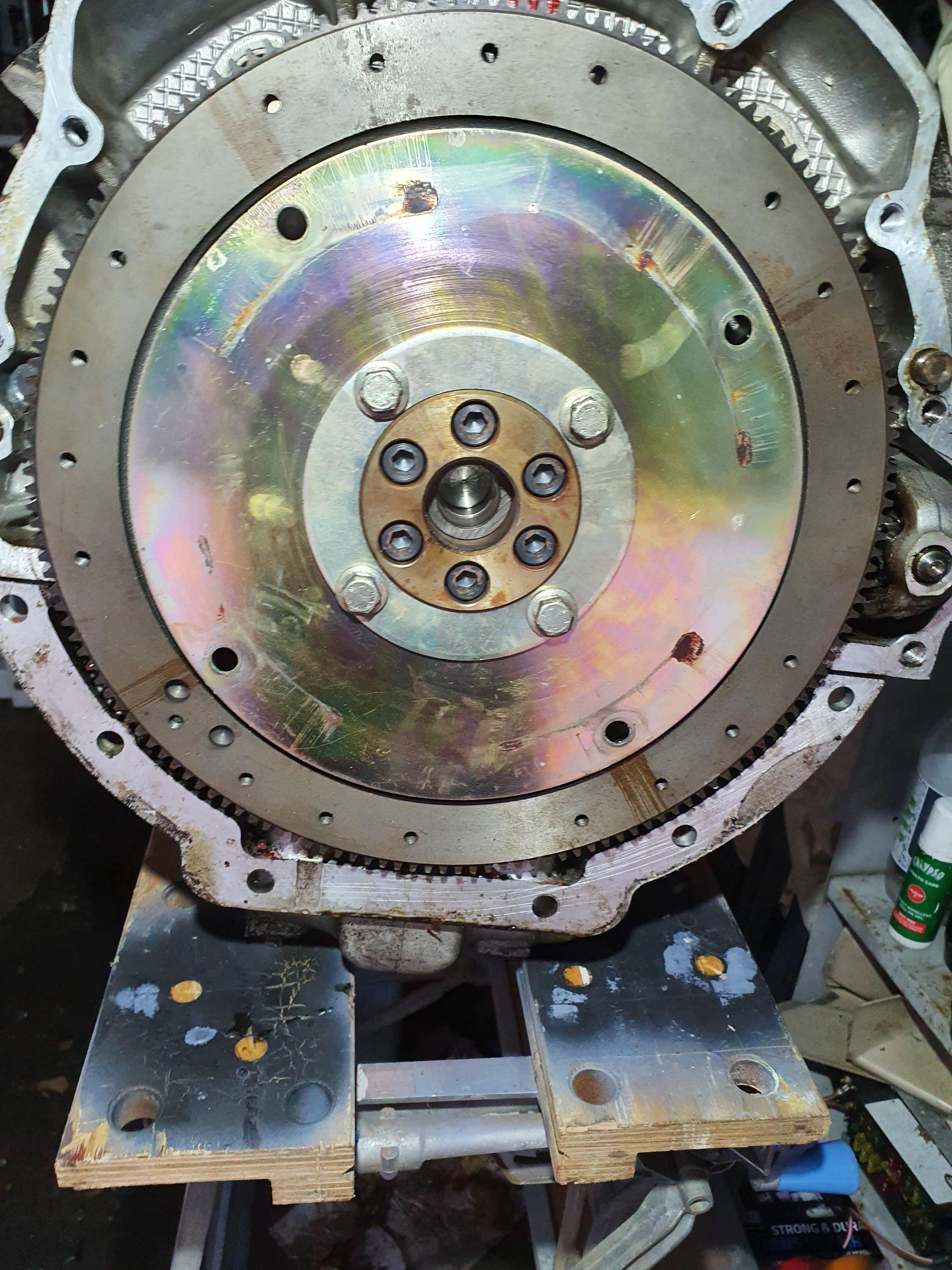

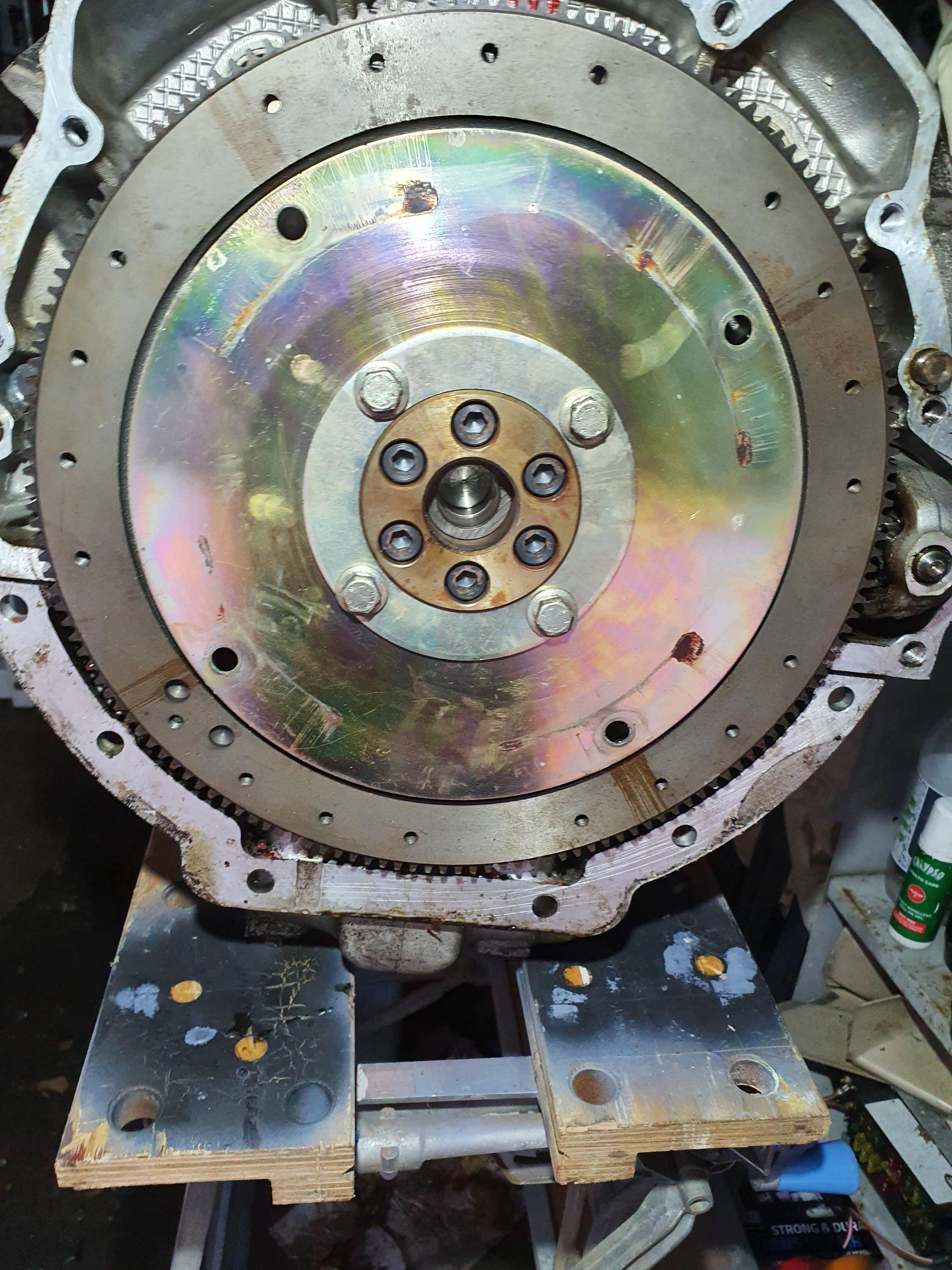

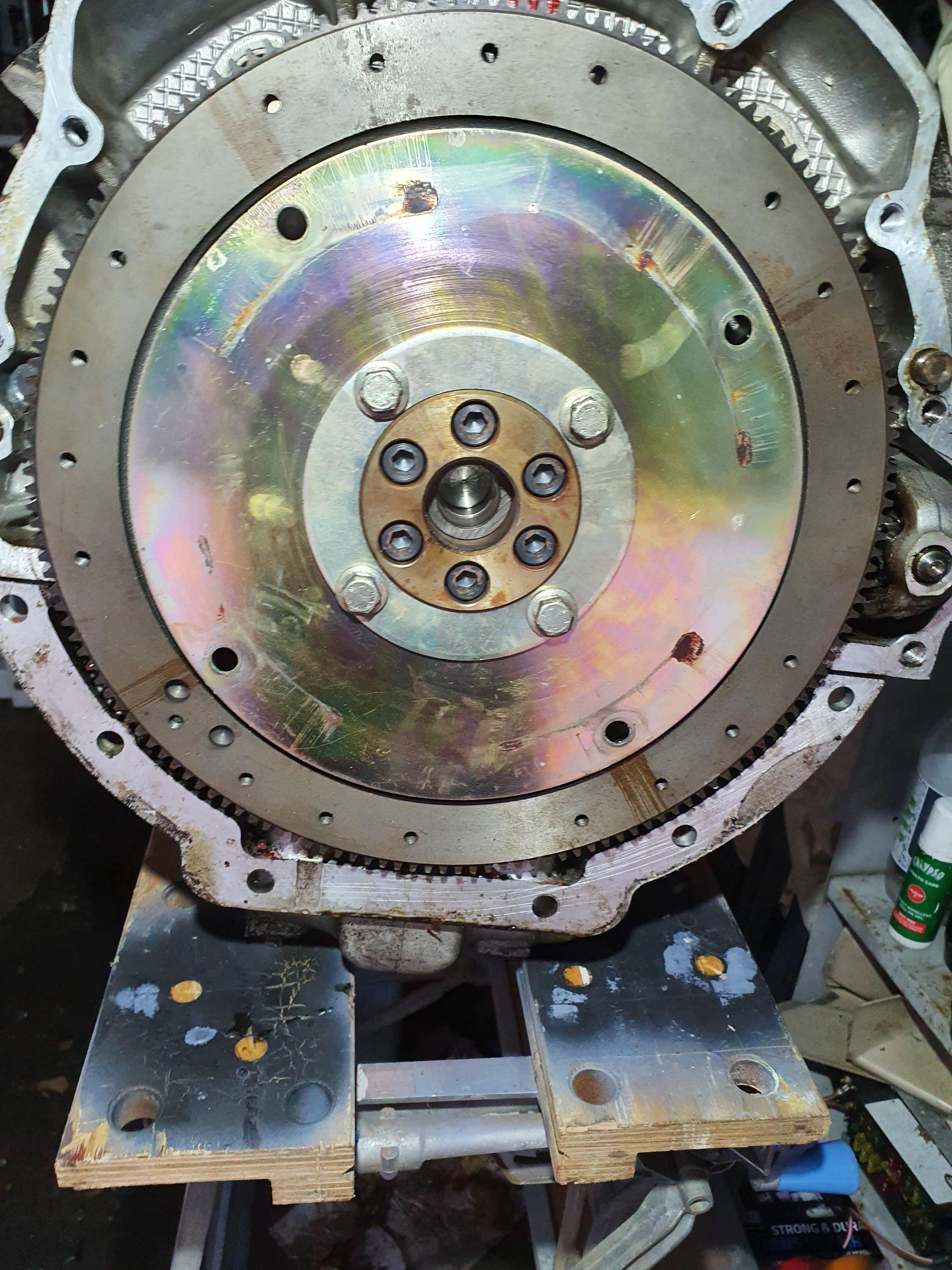

Good news is, the flexi plate is still in one piece

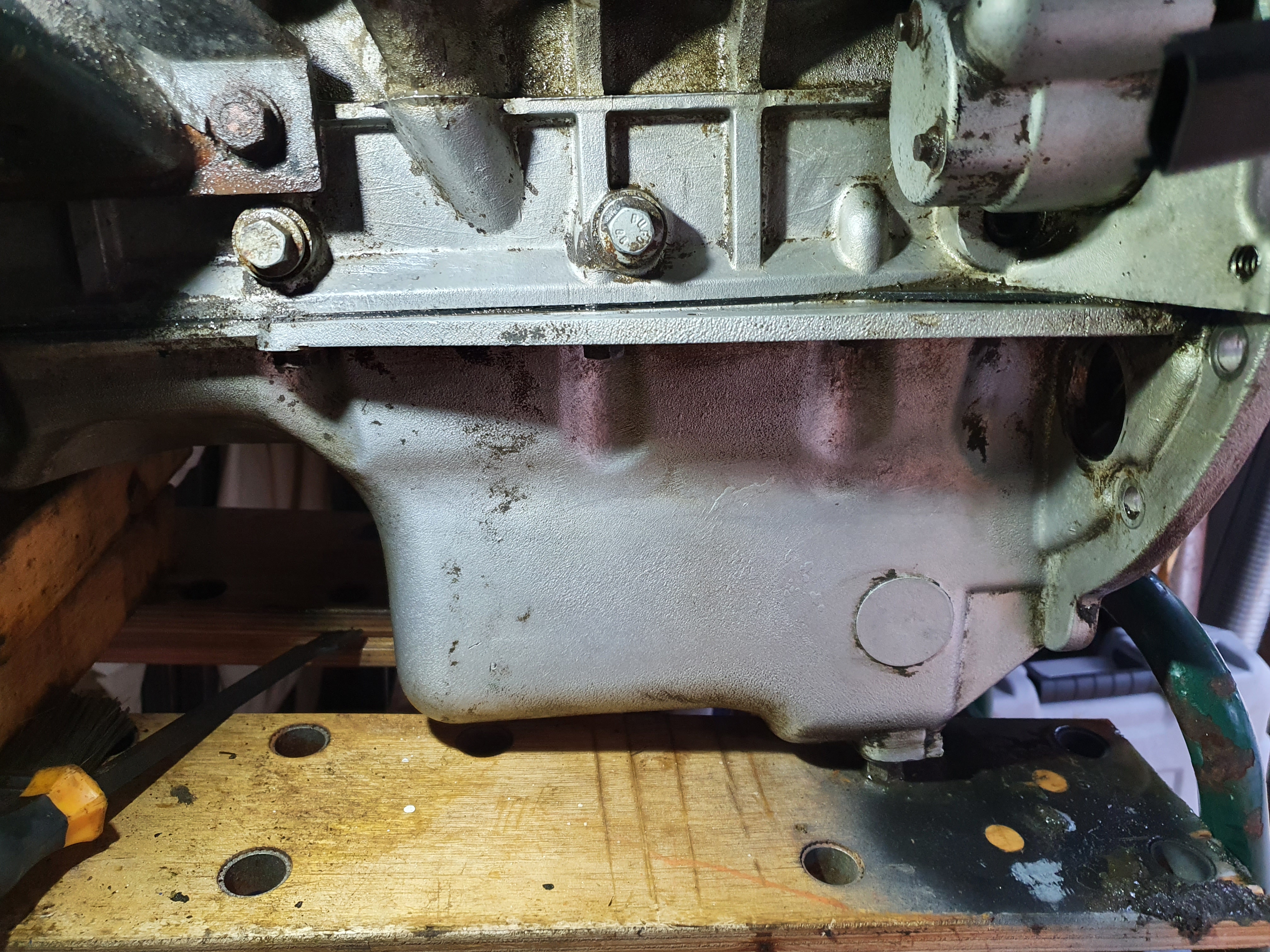

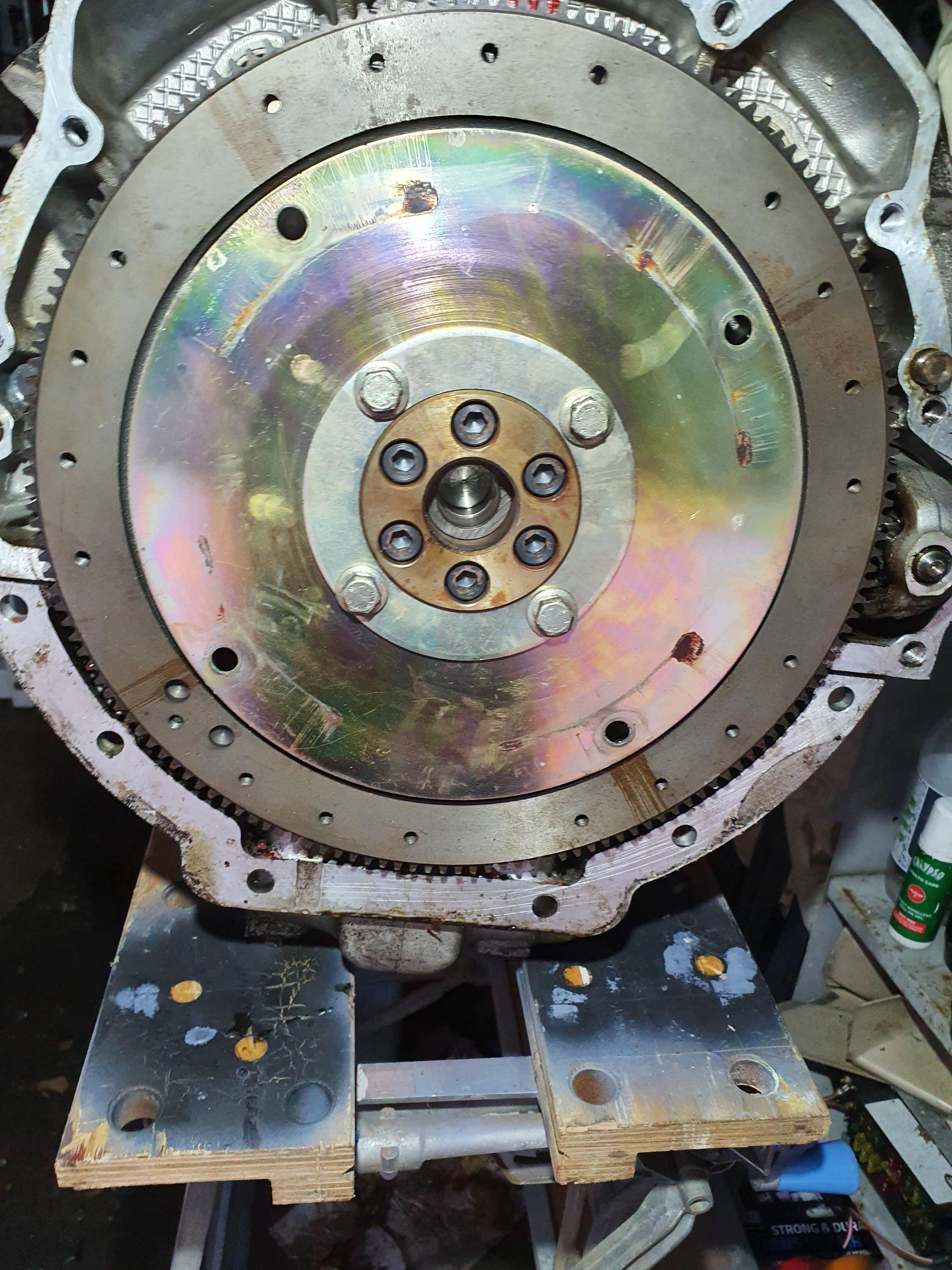

No leak from the rear crank shaft seal

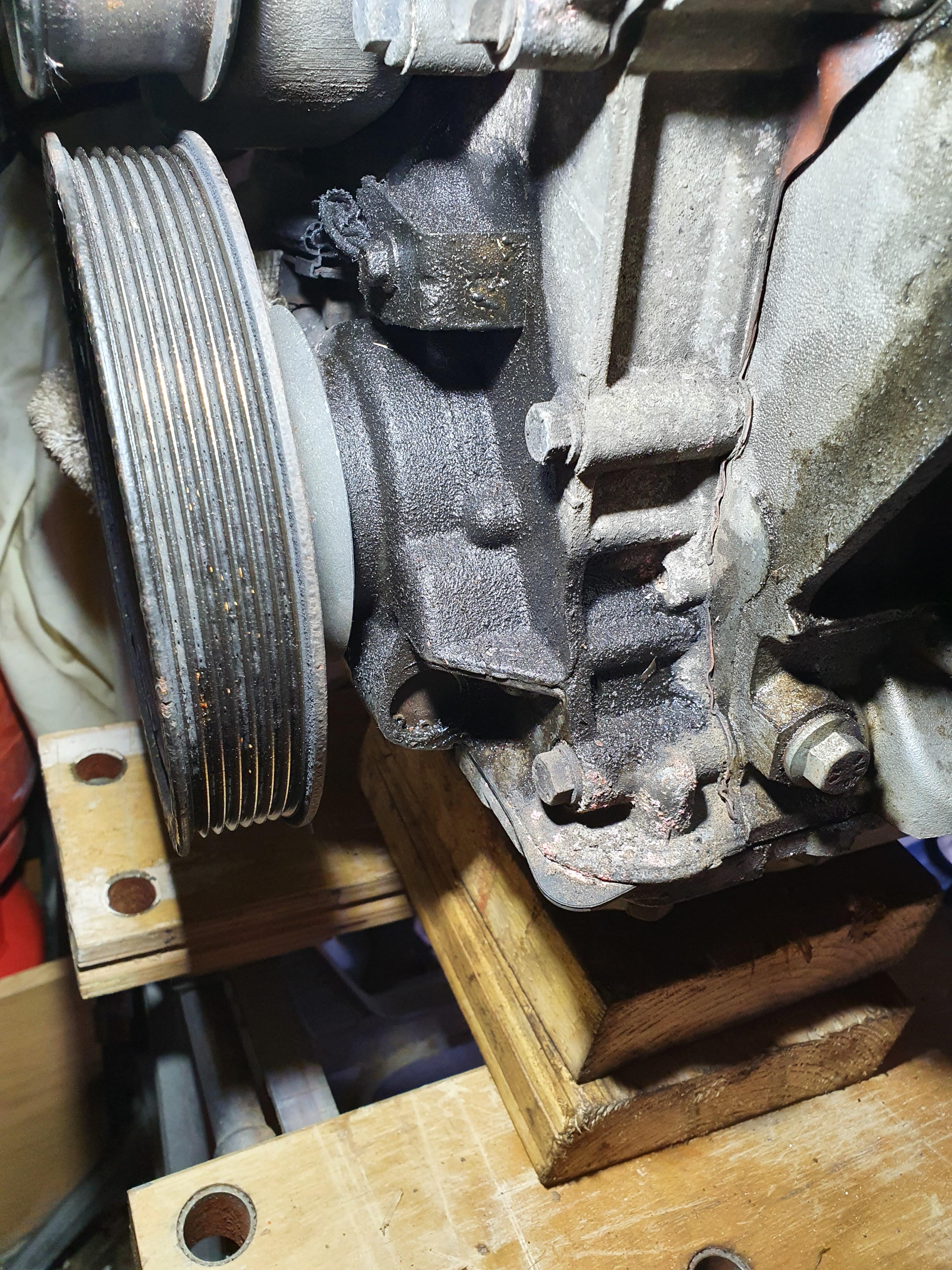

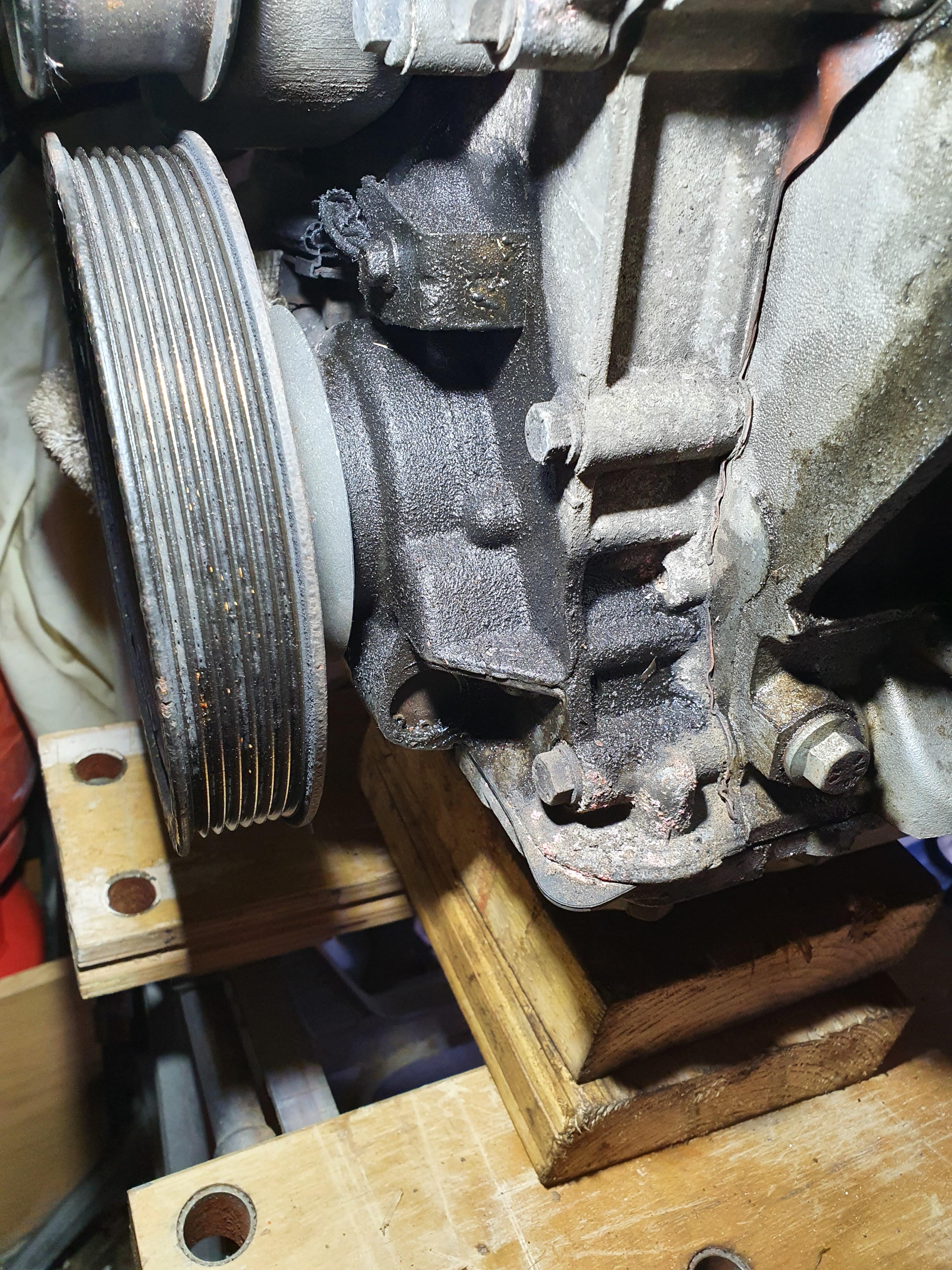

Shame can'r be said for the front crank seal

22k miles

Plenty room in the garage for the tools, bike, engine crane (in front of the bike...) and engine

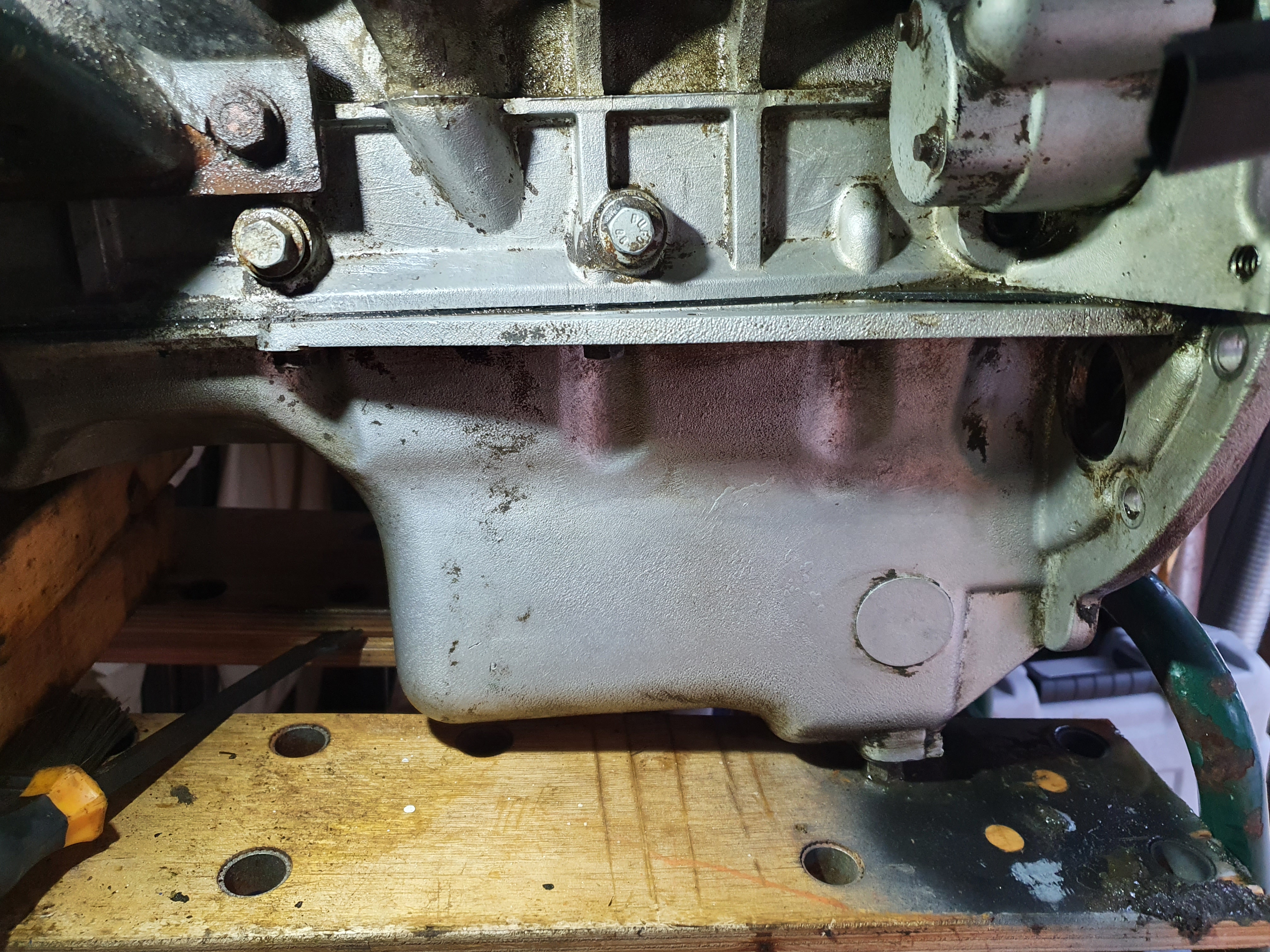

Started cleaning the muck off the lump....

And when the engine is all done and refitted, the cardboard box on the heater is the VERY expensive head gasket set. And I am pointing at the superb new head lining for the roof. Champagne colour which will be gorgeous

Yes I know I am pointing vigorously at the big black roll, but the box has all the gaskets....

So, it's all fun and games. What fun I'll have replacing the front crank oil seal

This happened with the bonnet still attached

Good news is, the flexi plate is still in one piece

No leak from the rear crank shaft seal

Shame can'r be said for the front crank seal

22k miles

Plenty room in the garage for the tools, bike, engine crane (in front of the bike...) and engine

Started cleaning the muck off the lump....

And when the engine is all done and refitted, the cardboard box on the heater is the VERY expensive head gasket set. And I am pointing at the superb new head lining for the roof. Champagne colour which will be gorgeous

Yes I know I am pointing vigorously at the big black roll, but the box has all the gaskets....

So, it's all fun and games. What fun I'll have replacing the front crank oil seal