dominicbeesley

Well-Known Member

- Posts

- 1,701

- Location

- Hebden Bridge, West Yorkshire

I'm about to go and try an electric fuel pump, my motor is running brilliantly after the ACR head and cam fitted but is running out of fuel under revs/load. Though it still managed 70mph up hill starting from 50 yesterday on M62 between Brighouse and Ainley top (quite steep long drag) and only pulling about 2,500rpm. Would just be nice to trust it overtaking though...

I've got one of these fuel pumps : SOLID STATE ELECTRIC FUEL PUMP / FACET CUBE TYPE PETROL LIFT PUMP | eBay and have made a bracket for it. I also got one of these pressure regulators: Pro-Flow Fuel Pressure Regulator SYTEC 8mm Tails [PRO54]. I really wanted a better one with a return but the bloke in the shop didn't know what was what and this one was the only one that made sense!

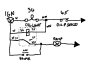

I'm going to wire it up like the attached diagram. Idea being when ignition is on but OIL pressure low the relay will pull in and switch OFF the pump. When started the OIL pressure will go up and switch OFF the relay and the pump ON.

I've got a dash mounted switch for priming the pump if need be.

Will this be safe enough? I might try and get hold of a fuel cut off switch but not sure where to look or what to get.

I've got one of these fuel pumps : SOLID STATE ELECTRIC FUEL PUMP / FACET CUBE TYPE PETROL LIFT PUMP | eBay and have made a bracket for it. I also got one of these pressure regulators: Pro-Flow Fuel Pressure Regulator SYTEC 8mm Tails [PRO54]. I really wanted a better one with a return but the bloke in the shop didn't know what was what and this one was the only one that made sense!

I'm going to wire it up like the attached diagram. Idea being when ignition is on but OIL pressure low the relay will pull in and switch OFF the pump. When started the OIL pressure will go up and switch OFF the relay and the pump ON.

I've got a dash mounted switch for priming the pump if need be.

Will this be safe enough? I might try and get hold of a fuel cut off switch but not sure where to look or what to get.

Attachments

Last edited: