Guess what, the EAS of the 1996 DSE that I own for 5 months now has started acting up. And not in the usual way: no faults registered, no beeps and no error messages. What happened is that it would go fine and than, especially after accelerating from standstill in a traffic light, the front would kneel and would not adjust for several minutes. Out of town its bearable, but running in town means that you are nearly constantly on the bump stops. No leaks detected in the usual testing ways, so I called upon my MSV2 for help.

The nice thing with the MSV2 and my laptop, is that you can monitor the behavior of the EAS system in (nearly) real time while driving. You get a page like the one attached, EAS monitoring. As the system go through its paces, you can follow the valves as they open and close and the heights being adjusted accordingly.

It turned out that indeed, as I was accelerating from standstill, FRONT LEFT VALVE STATES and FRONT RIGHT VALVE STATES changed to OPEN for few seconds, then quickly closed. These brief seconds were enough to nearly empty the front air springs and cause the faulty behavior.

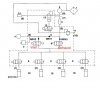

At first I suspected the ECU or the Driver pack: after all, why open these two valves when the car starts moving? it made no sense to me (still doesn't, btw). But then I looked at the air-system diagram from rave, depicted as the second attachment (Air path) here. From the diagram it immediately became clear that, even if the spring valves are open, air should not escape unless the exhaust valve is also open :doh:. On the next run I made sure that it indeed remains closed, so air must be escaping, most probably through a leaky exhaust valve. (a leaky Inlet valve would be the next bet.)

I quickly emptied the system's air, and with the valve block still mounted on the car (not recommended...) I undid the valve, cleaned it and replaced the o-rings, never to see the problem again (its been two weeks...).

Just thought I'd share this with you, and even add my conclusions: even strange and quirky behavior can, and most likely does, come from faulty o-ring in the valve block.

The nice thing with the MSV2 and my laptop, is that you can monitor the behavior of the EAS system in (nearly) real time while driving. You get a page like the one attached, EAS monitoring. As the system go through its paces, you can follow the valves as they open and close and the heights being adjusted accordingly.

It turned out that indeed, as I was accelerating from standstill, FRONT LEFT VALVE STATES and FRONT RIGHT VALVE STATES changed to OPEN for few seconds, then quickly closed. These brief seconds were enough to nearly empty the front air springs and cause the faulty behavior.

At first I suspected the ECU or the Driver pack: after all, why open these two valves when the car starts moving? it made no sense to me (still doesn't, btw). But then I looked at the air-system diagram from rave, depicted as the second attachment (Air path) here. From the diagram it immediately became clear that, even if the spring valves are open, air should not escape unless the exhaust valve is also open :doh:. On the next run I made sure that it indeed remains closed, so air must be escaping, most probably through a leaky exhaust valve. (a leaky Inlet valve would be the next bet.)

I quickly emptied the system's air, and with the valve block still mounted on the car (not recommended...) I undid the valve, cleaned it and replaced the o-rings, never to see the problem again (its been two weeks...).

Just thought I'd share this with you, and even add my conclusions: even strange and quirky behavior can, and most likely does, come from faulty o-ring in the valve block.