johnnyoxford

New Member

- Posts

- 200

- Location

- Bucks

Hi

I have oil leaking from my rear hub, 200 tdi 90 (1993) defender.

I have been advised to replace the wheel bearings and seals. Ordered what I thought I needed from paddocks.

Stripped it today. No major dramas getting the hubs off, cleaning up, replacing bearings and seals either side of them.

Now as I looked at it to put it back together, I stopped, because I cannot see how replacing the wheel bearing seals will stop this leak:

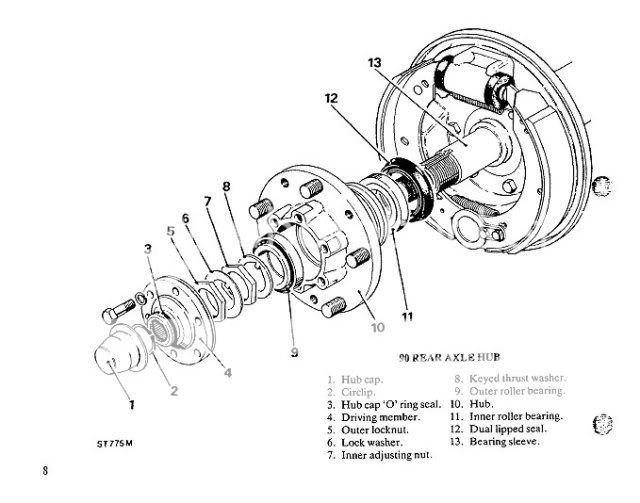

The oil is in the diff and comes down the axle right? And as far as I can see there is nothing to stop it coming down the splines of the half shaft, and out of the hub, apart from a poxy rubber cap that sits on the end after the circlip.

Am I right? Or am I being daft here? There was a fair oil leak before, and streaks all around the wheel.

When I got it apart there was also oil inside the brak drum, could this have run out to the end of the half shaft and then back in through the bearings and seals?

Please help me tonight as I have stopped in case I put it all back together without resolving the problem.

I am wondering if there is an oil seal between the stub axle and the main axle housing? I dont however think the leak is there, as the oil evident in the brake drum was inside the drum on the backplate behind the shoes. Surely if it was leaking from the stub axle flange then the oil would be on the outside?

Hope this makes some sense, I am driving myself mad here.

I have oil leaking from my rear hub, 200 tdi 90 (1993) defender.

I have been advised to replace the wheel bearings and seals. Ordered what I thought I needed from paddocks.

Stripped it today. No major dramas getting the hubs off, cleaning up, replacing bearings and seals either side of them.

Now as I looked at it to put it back together, I stopped, because I cannot see how replacing the wheel bearing seals will stop this leak:

The oil is in the diff and comes down the axle right? And as far as I can see there is nothing to stop it coming down the splines of the half shaft, and out of the hub, apart from a poxy rubber cap that sits on the end after the circlip.

Am I right? Or am I being daft here? There was a fair oil leak before, and streaks all around the wheel.

When I got it apart there was also oil inside the brak drum, could this have run out to the end of the half shaft and then back in through the bearings and seals?

Please help me tonight as I have stopped in case I put it all back together without resolving the problem.

I am wondering if there is an oil seal between the stub axle and the main axle housing? I dont however think the leak is there, as the oil evident in the brake drum was inside the drum on the backplate behind the shoes. Surely if it was leaking from the stub axle flange then the oil would be on the outside?

Hope this makes some sense, I am driving myself mad here.