sierrafery

Well-Known Member

- Posts

- 18,315

- Location

- Arad/Romania

I thought to share this for posterity  :

:

Check fuel pump HP (the easy way)

Post by sierrafery » March 23rd, 2020, 3:25 am

Hi all. Based on the interventions of vkssmika and damyan_rm here viewtopic.php?p=751638#p751638 i worked out the easy way to see if the Td5 fuel pump is working as it should or not cos it's quite common to hear it running but the HP stage to be dead while the pump is still running on LP which can cause low power, missfire or non-start

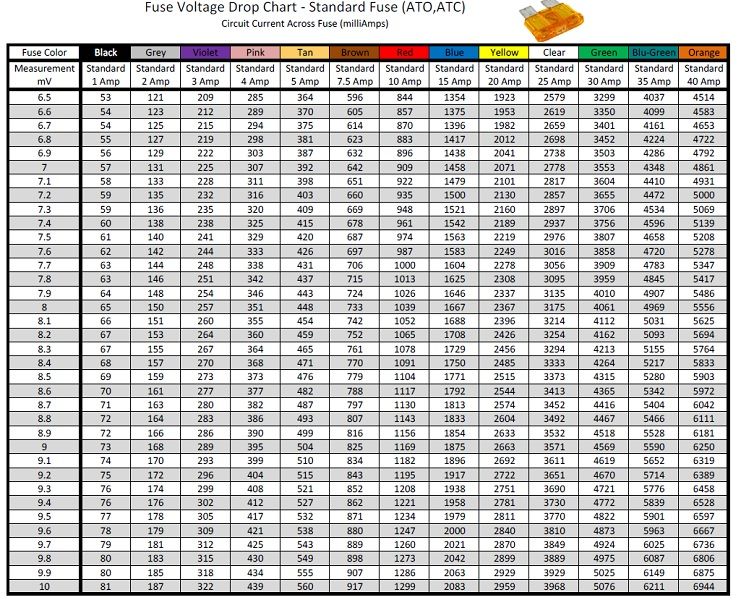

So: with multimeter set on mV measure across the pins of fuse F10(30A) in situ, (multimeter probes like this):

while the pump(or engine) is running, according to the attached chart by mutiplication if the HP is working you should get around 23.mV reading(or more) which means around 13A current draw , if it's only around 10mV or below(= 5A draw) the HP is dead but the pump is still running on LP

while the pump(or engine) is running, according to the attached chart by mutiplication if the HP is working you should get around 23.mV reading(or more) which means around 13A current draw , if it's only around 10mV or below(= 5A draw) the HP is dead but the pump is still running on LP

**(i'd say that -1mV reading for HP should be acceptable)

Attachments

Check fuel pump HP (the easy way)

Post by sierrafery » March 23rd, 2020, 3:25 am

Hi all. Based on the interventions of vkssmika and damyan_rm here viewtopic.php?p=751638#p751638 i worked out the easy way to see if the Td5 fuel pump is working as it should or not cos it's quite common to hear it running but the HP stage to be dead while the pump is still running on LP which can cause low power, missfire or non-start

So: with multimeter set on mV measure across the pins of fuse F10(30A) in situ, (multimeter probes like this):

**(i'd say that -1mV reading for HP should be acceptable)

Attachments

Last edited: