holidaychicken

Well-Known Member

- Posts

- 4,014

- Location

- Kent

Hi all, again..

I am looking into a few issues with my 4.4 petrol 2004 engine, just trying to make sure it is running as it should and not causing my transmission issue from my other thread if somebody can help.

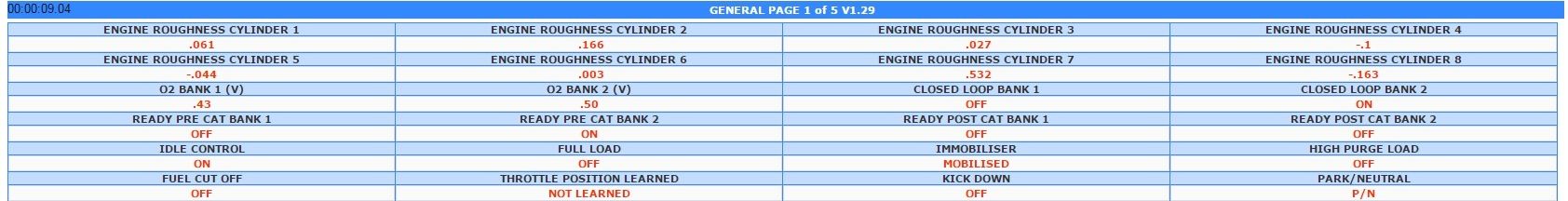

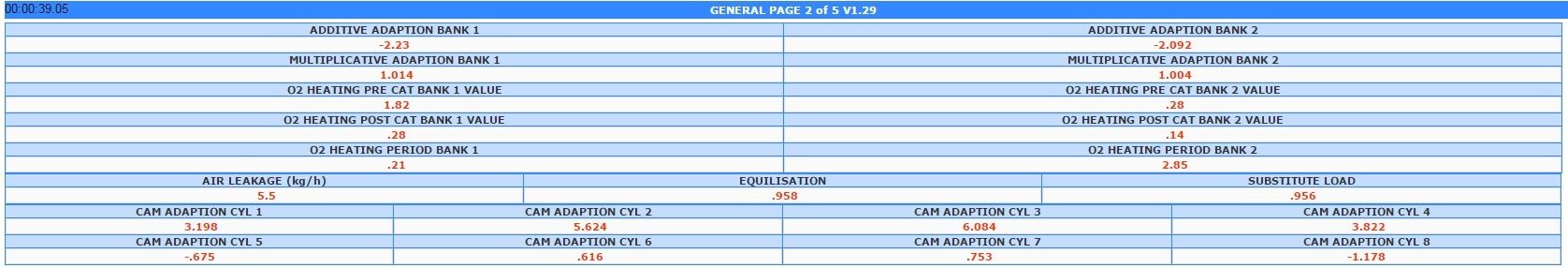

I have run a few diagnostic reports using a faultmate and there are a couple of readings that don't look right to me that i have attached.

In particular i am looking at the cam adaption values being very different for the two different banks which is shown in degrees. I believe the adaption values should be between 0, fully retarded and 20 degrees fully advanced.

The throttle position shows as unlearned so i cleared the adaption values which put it into an emergency mode and it then showed as learned but then very quickly returned to unlearned although i may not have carried out the procedure correctly.

The air leakage showed at around 5 kg/h so I cleaned the MAF sensor and throttle body and really made sure i put it back correctly and sealed it but the total air flow increased and the leakage increased to around 10 kg/h, but weirdly, if i wiggle the wires connected to the MAF sensor, the value will drop to around 8 kg/h.

Anyone make any sense of these please, i have other pages of information as well.

Many thanks

Andy

I am looking into a few issues with my 4.4 petrol 2004 engine, just trying to make sure it is running as it should and not causing my transmission issue from my other thread if somebody can help.

I have run a few diagnostic reports using a faultmate and there are a couple of readings that don't look right to me that i have attached.

In particular i am looking at the cam adaption values being very different for the two different banks which is shown in degrees. I believe the adaption values should be between 0, fully retarded and 20 degrees fully advanced.

The throttle position shows as unlearned so i cleared the adaption values which put it into an emergency mode and it then showed as learned but then very quickly returned to unlearned although i may not have carried out the procedure correctly.

The air leakage showed at around 5 kg/h so I cleaned the MAF sensor and throttle body and really made sure i put it back correctly and sealed it but the total air flow increased and the leakage increased to around 10 kg/h, but weirdly, if i wiggle the wires connected to the MAF sensor, the value will drop to around 8 kg/h.

Anyone make any sense of these please, i have other pages of information as well.

Many thanks

Andy