Discodad

Well-Known Member

- Posts

- 1,844

- Location

- East Anglia

Brought this Disco back in Feb with what looked to be a prefect boot floor.

Should have known better really. I was (and still am) very tempted to break it but the running gear is very good, achieves 30mpg (even with my heavy right foot) and it has no ABS, no airbags and no aircon.

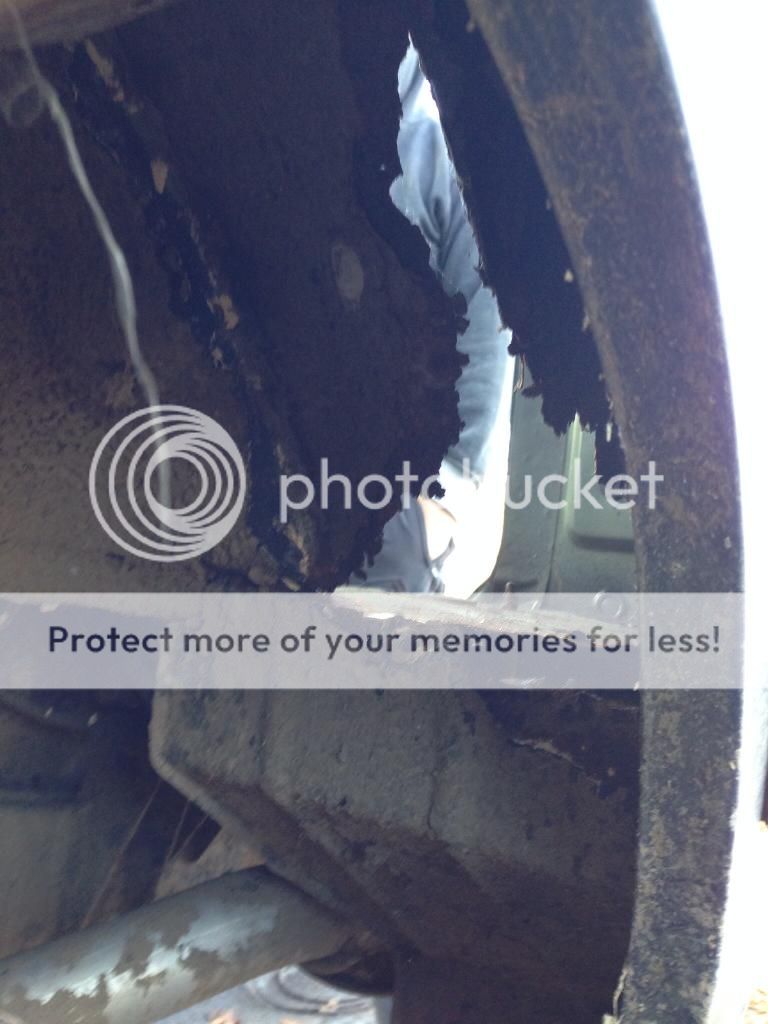

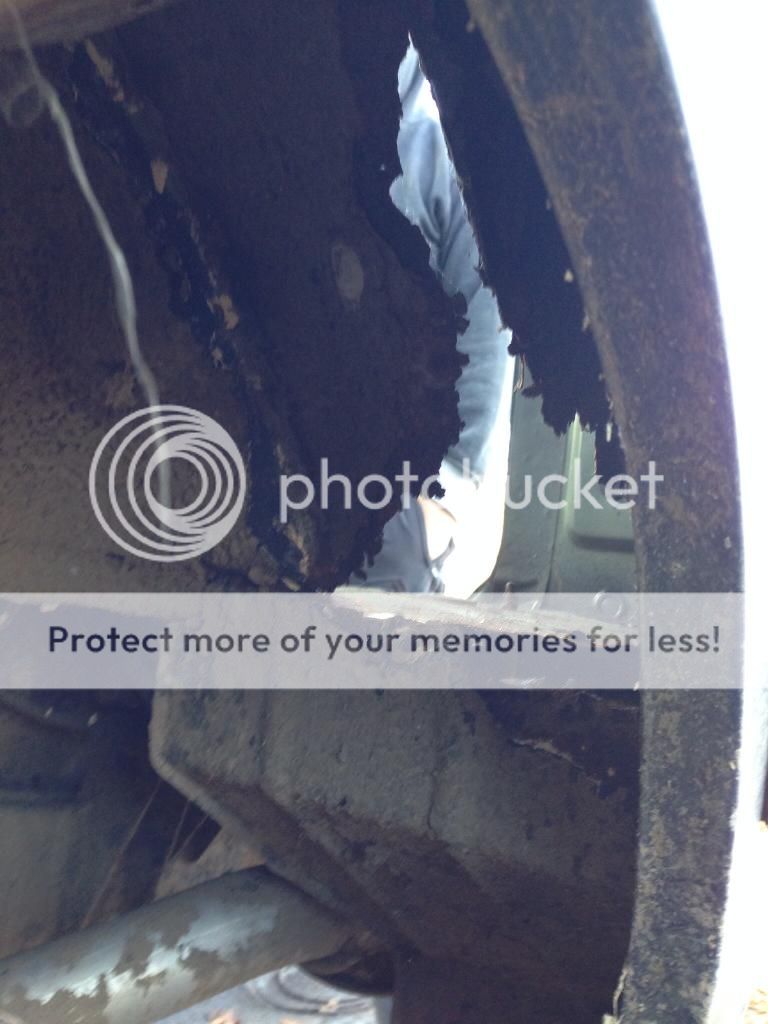

I took it off the road when the MOT expired as I had already found some holes in the rear cross member. We have a laning holiday booked for Feb so thought we'd make a start on getting it sorted.

It just kept getting worse and worse and worse. We haven't even took the sill covers off yet

So many of the holes had been packed out, filled with putty and then undersealed over the top. What a complete total waste of time and effort

Lots of metal patches just riveted in

Then we started seeing what was solid

Then we cut out the rust to see what was left:

Bit daunted by it all tbh.

I welded at college about 20 years ago so hoping it will come back and we are very lucky to have the use of a workshop in the evenings and weekends.

Current thoughts are to buy:

Boot panel.

The three boot floor supports.

side panels.

I want to repair the arches as Auf_wiedersehen_pet's did in his thread as they are shockingly expensive to buy.

I would rather repair the cross member as the replacement panel is expensive and it looks difficult to replace.

I'll take plenty of photos as we repair it and hopefully get it ready for the welch green lanes.

Should have known better really. I was (and still am) very tempted to break it but the running gear is very good, achieves 30mpg (even with my heavy right foot) and it has no ABS, no airbags and no aircon.

I took it off the road when the MOT expired as I had already found some holes in the rear cross member. We have a laning holiday booked for Feb so thought we'd make a start on getting it sorted.

It just kept getting worse and worse and worse. We haven't even took the sill covers off yet

So many of the holes had been packed out, filled with putty and then undersealed over the top. What a complete total waste of time and effort

Lots of metal patches just riveted in

Then we started seeing what was solid

Then we cut out the rust to see what was left:

Bit daunted by it all tbh.

I welded at college about 20 years ago so hoping it will come back and we are very lucky to have the use of a workshop in the evenings and weekends.

Current thoughts are to buy:

Boot panel.

The three boot floor supports.

side panels.

I want to repair the arches as Auf_wiedersehen_pet's did in his thread as they are shockingly expensive to buy.

I would rather repair the cross member as the replacement panel is expensive and it looks difficult to replace.

I'll take plenty of photos as we repair it and hopefully get it ready for the welch green lanes.