WightinNL

Member

- Posts

- 24

- Location

- UK & Netherlands

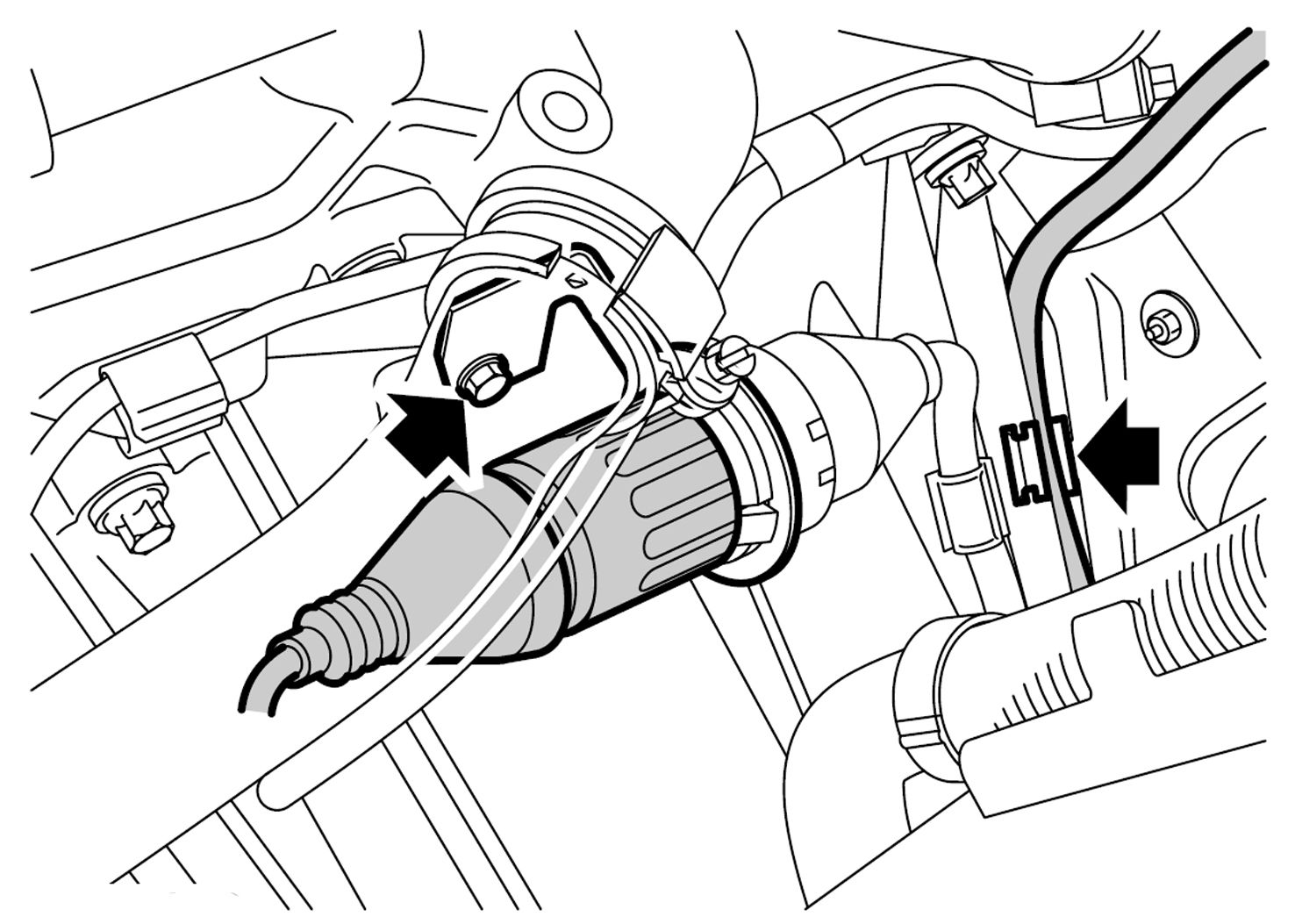

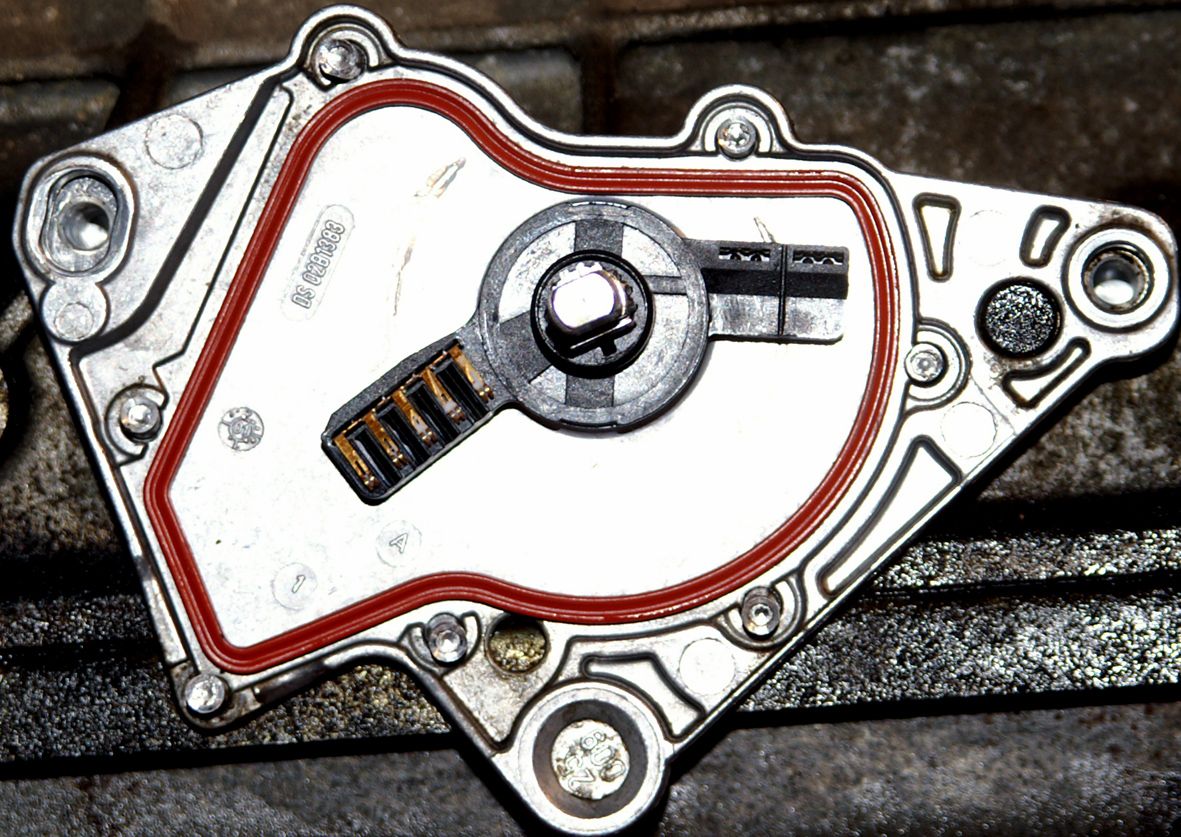

Hi Guys, as a recent member - but frequent reader of your forum, I very much appreciate all your advice and experience shared. I too have the Trans Prog Fail message, accompanied by P0705 which is persistent to the extent that I can no longer move the car. If “P” doesn’t appear on the dash on start up, it disappears as soon as touch the shift. It did once manage to move when starting up in neutral. Although i dont have much auto electronic/engineering experience I am an engineer so ought to be able to diagnose/trace faults/follow Bembers superb instructions etc. I’m hampered by working away in Netherlands, and while I brought a selection of tools - I dont quite have everything I would want, and certainly no ramps. I guess I thought the easiest way to test the switch continuity would be at the ECU plugs, but I find my meter prongs too fat to be useful. So onto the harness plug - yes I can just about reach it, but couldn’t separate the two halves - can anyone tell me (as I couldn’t see) if there is a tab to press, or need a small screw driver to pop in and release? So on to the switch for a visual on internals - now I’m not the skinniest of chaps so getting underneath with enough elbow room to work with is a challenge but cable off, cover plate off and switch released from gearbox - I cant appear to slide the switch off the splined shaft - can anyone tell me if there is a circlip holding it on inside the switch? Anyway snow here too today, so I guess I wont be under it again tonight... Thanks in advance for your tips on the plug release and possibility of circlip inside the switch. Will keep you posted as to results - success or otherwise