Morning, Another weekend of work on the rebuild and few things I'm a little unsure of. A lot of the time I can tell once I've ripped it out/apart

As always, any help/info/advice is always appreciated!

- Nyloc nuts. I'm amidst a rebuild. Some nuts i.e. shock nuts are just plain, others are nyloc. Is the norm to measure pitch/size and just buy in replacement nyloc nuts for anything I take out that's nyloc? Do I need to make sure I get a certain one i.e. high tensile? I'd assume these nuts seal down when torqued which makes me think theyre one use only...

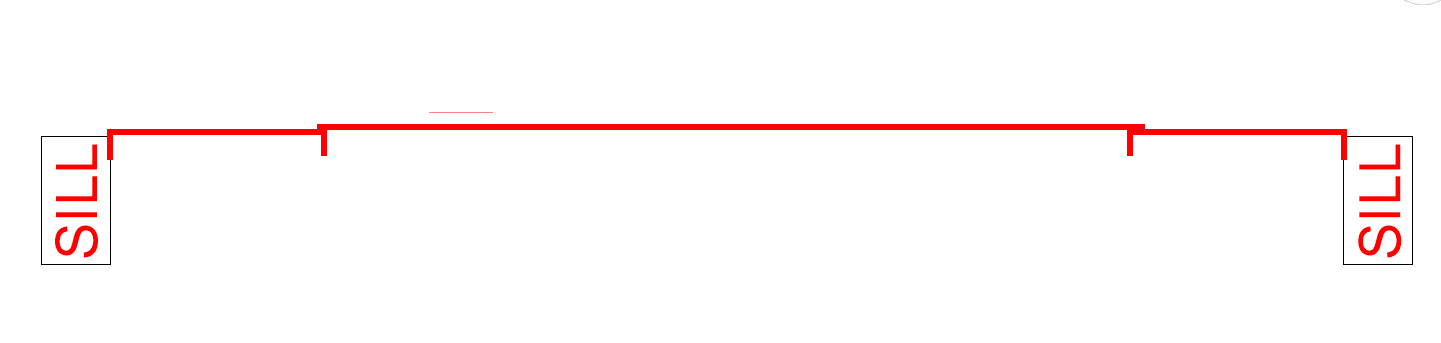

- D1 Floor pan (front seats and rear footwell) - It looks to be double skinned to a certain extent? From what I can see, There's almost an upside down 'U' shape of plate that tabs to the sills then about a foot towards the centre. It looks like the gap down the centre is single skin and sits on top of this?

- Panel Mastik - Whats your favourite to make a water tight, Silicone free seal? I will need it for re-installing the rear quarters. The stuff that was on there stuck like sh!t and seemed to be bitumen based..

As always, any help/info/advice is always appreciated!