steve2286w

Well-Known Member

- Posts

- 5,208

- Location

- monkeyangerland

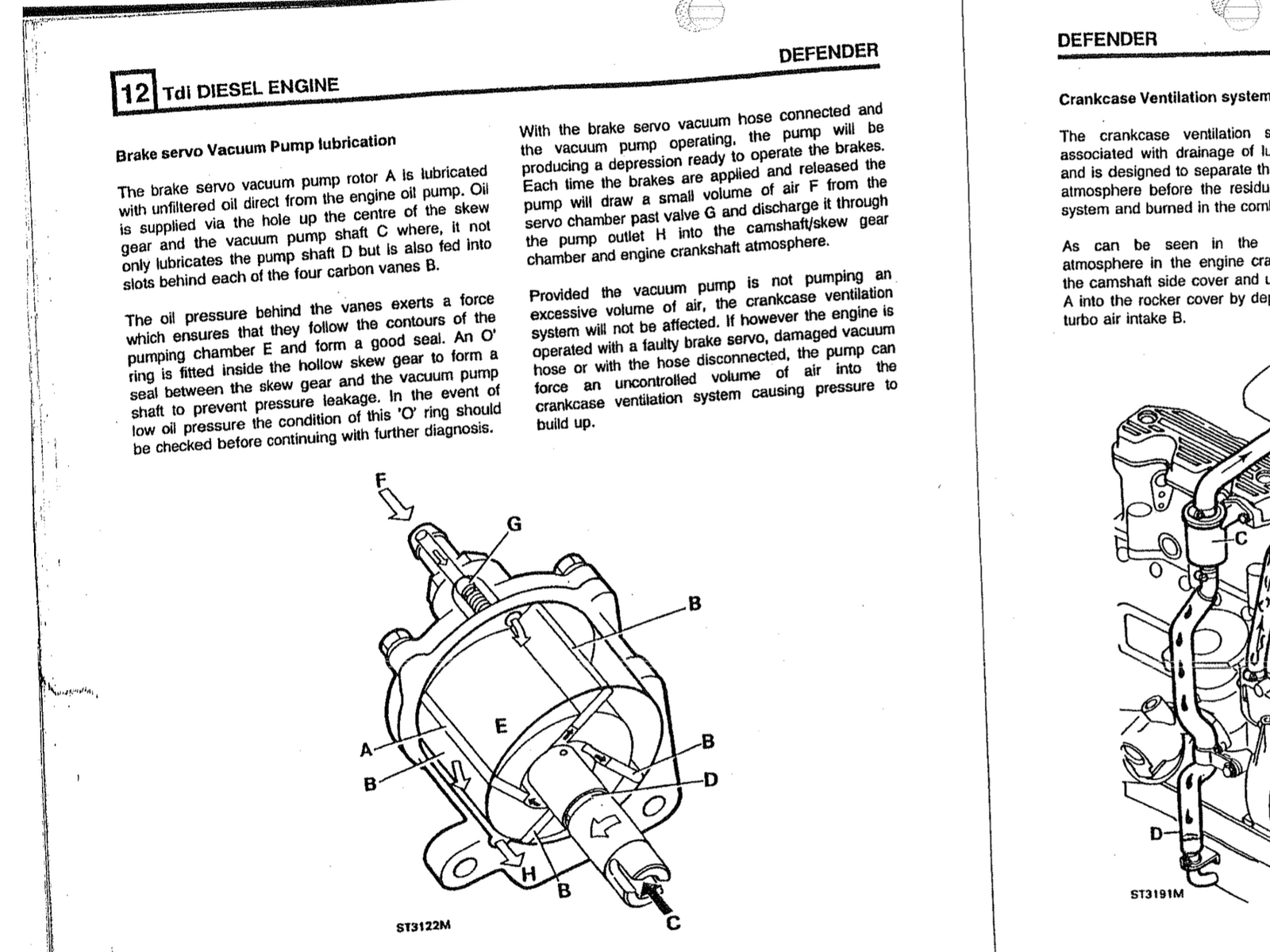

Just replaced the o rings in my vac pump inside one was a sod, if hardened and flat , can cause a loss of oil pressure

Did you have low oil pressure? Is that why you decided to change the O rings?Just replaced the o rings in my vac pump inside one was a sod, if hardened and flat , can cause a loss of oil pressure

View attachment 188300

Ok Steve, cheers. Even if mine is venting too much air in to the crankcase I don't know if that would cause my oil consumption. Worth investigating though. However, I fear it's going to need something a bit more drastic.I was refurbing my 200tdi engine , pumps a bit different on 200tdi but may be same principle both o rings completely flat

That's very generous. The vac pump looks as though it's pulling ok at the servo, so must be continuously pulling air in from elsewhere. I think I'll just have to bite the bullet at some point and take the head off to have a look.Any leak on the suction side would affect the level of the vacuum level and affect your braking.

When you put your thumb over the end and you can feel the vacuum that should be how the system is at normal running.

I removed the EGR and plugged the pipe with a silicone plug and a cap you can find silicone caps on tbay which do a good job.

I have a druck electronic pressure gauge which will measure + pressure or - pressure you are welcome to borrow it if it will help you.

https://www.ebay.co.uk/itm/Silicone...ff-Bung-Pipe-4m-19mm-/174006350904?nav=SEARCH

I think I'll just have to bite the bullet at some point and take the head off to have a look

Cheers, Goc3k. Yes, I've been googling vac pumps and the different methods of operation. Mine is obviously pulling a decent vacuum, so I might have a leak somewhere. The servo is new, so unlikely that. When I put the new servo on I replaced the small bit of hose between the servo and the vac pipe. The old one was chewed and deteriorating. I used a bit of fuel tank breather hose, which was an easy slide fit on to the servo. It's got appropriately sized jubilee clips on though, so I reckon it's ok. I've tried the palm of my hand over the oil filler in the rocker cover. I might be able to feel the slightest chuff of air on my palm, but then the wind from the viscous fan makes it hard to tell. If it's so difficult to notice any possible blow by then perhaps that's not an issue either. I appreciate you mentioning the vac pump though and remembering to connect it to this thread after such a long time.To clarify, the 300tdi vac pump is a piston style pump not rotary vane like on a 200tdi or td5, and it wont cause much oil loss directly, but it is the indirect effect of it pressurizing the crankcase (if it fails in a certain way) which increases oil consumption - if it pulls a good vacuum on your finger the internal check valves and seals are working, but if say the brake booster had a small split in it or the hose that connects it to the vac pump (not necessarily a visible hole) that can cause a lot of air to pass into the crankcase, as long as the pump isnt pulling from atmosphere directly it'll pass little to no extra pressure into the crankcase

look up windage and excessive crankcase pressure to see how it causes oil consumption - equally it presents as blowby does (i.e the old cap dance test of the oil filler), so if that isnt happening chances are all is well and the mystery continues.

Also all the vac pumps are made in the same factory in turkey by Unipump - (supposedly)

I might be able to feel the slightest chuff of air on my palm

Are you thinking the boroscope could go down an injector hole?

A drag indeed. I keep putting off what seems to be the inevitable. I promised myself I'd do it this summer, but obviously haven't. Next I'll be telling myself it's too cold and wet to be doing itSounds like it's all good then probably re vac leaks.

If the cap stays level / only slight vibration (but not lifting) when undone it's fine.

Down a glowplug port I was thinking for ease of insertion - one with a small light and manual focus so you can see and sharpen up the image. Maybe it's a bit pointless, suppose you cant really see much past the piston edges as the camera will be stuck facing it - just such a drag taking the head off possibly for nothing!

Not sure, it was an OEM Elring one from Turners.I had not noticed, been busy these last light evenings wasting my time on non landy projects!

Right bugger about the head gasket, interesting about the oil pressure as well - no doubt somehow related?

Did you use an MLS head gasket during the rebuild?

Yeah, I'm thinking it must all be related and pointing towards the head gasket. Looks like the expansion tank has split as it's weeping along the seem. I'm thinking it must be possible for the oil to be pressurised down an oil way towards the pressure sensor, so the way out via the vent to induction pipe work doesn't relieve the pressure?I had not noticed, been busy these last light evenings wasting my time on non landy projects!

Right bugger about the head gasket, interesting about the oil pressure as well - no doubt somehow related?

Did you use an MLS head gasket during the rebuild?

I'm thinking it must be possible for the oil to be pressurised down an oil way towards the pressure sensor, so the way out via the vent to induction pipe work doesn't relieve the pressure?

Yeah, it would definitely be venting out through breather, just thought if the HG has gone, it might have gone in to an oil way creating a bit of pressure leading to the pressure sensor. Explaining the oil pressure being high for a while. I don't knowIt'll probs be worth swapping it for a quality old school fibre gasket if turns out you did put a MLS one on, I know they tend to not last well on old blocks.

It probably is helping relieve it a fair amount, otherwise something would go bang be it a vent hose or gasket etc if there was enough trapped pressure in the crankcase.

Looking forward to that pic of the bores...!

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!