RangeRoller dt

Well-Sprung Member

- Posts

- 14,413

- Location

- Trapped inside my head @ LZ asylum

In this hot hot weather cutting out at junctions is getting regular. Coupled with hot start issue it’s getting undrivable in summer but okay in winter, manageable at night.

Wammers told me day1 as a newb - read up, get the tools and get it done.

Thanks to Bagshot I have the tools, and thanks to everyone here I have the knowledge and skills (in theory

)

)

Not working tomorrow so plan is to try get it done accurately with whole day set aside just incase I start to snap things. Got home late today but made a start, surprised how much easier & quicker it is now I’m more familiar. being clean compared to the sh*t bucket I had at first makes things betterer.

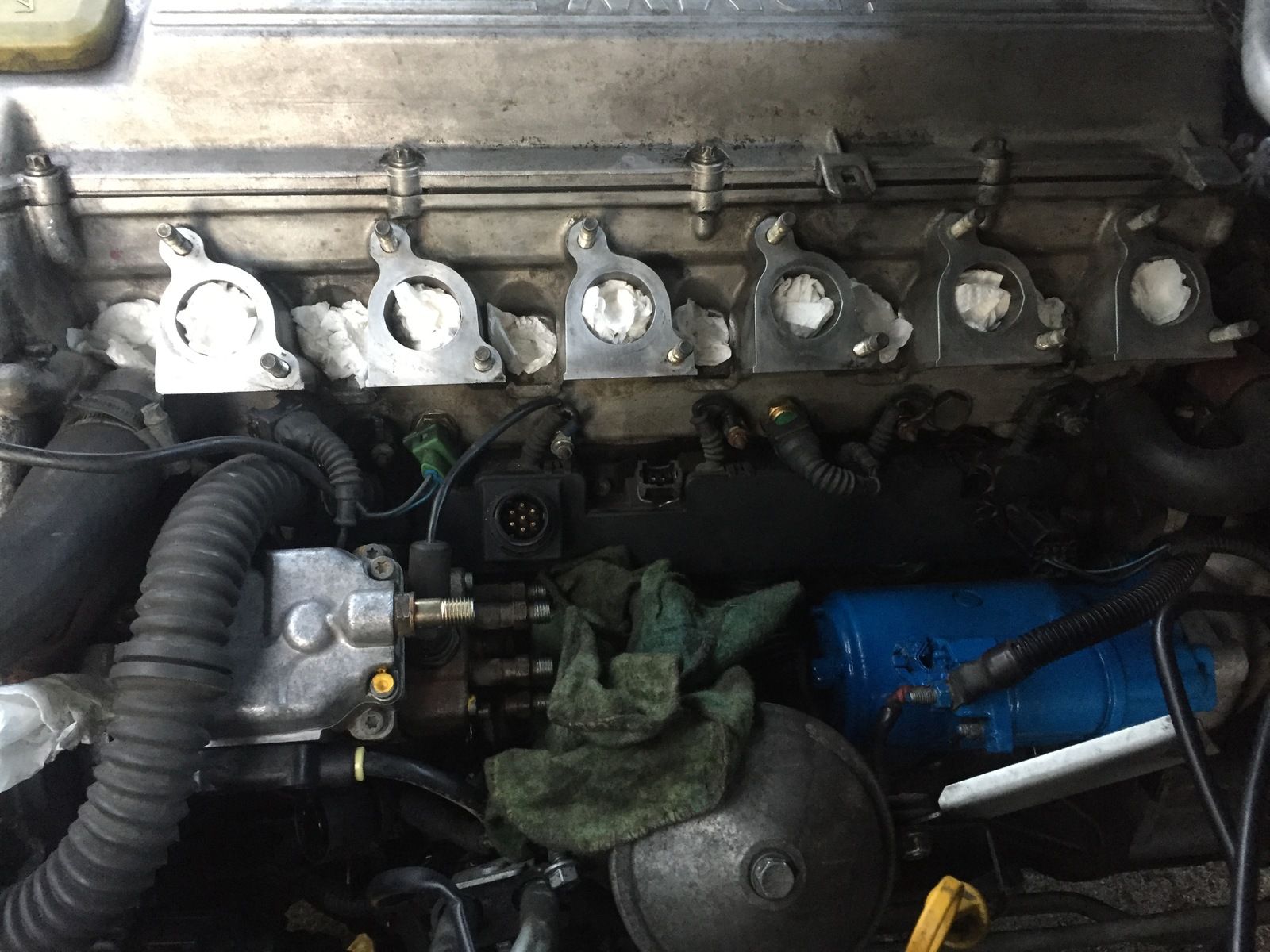

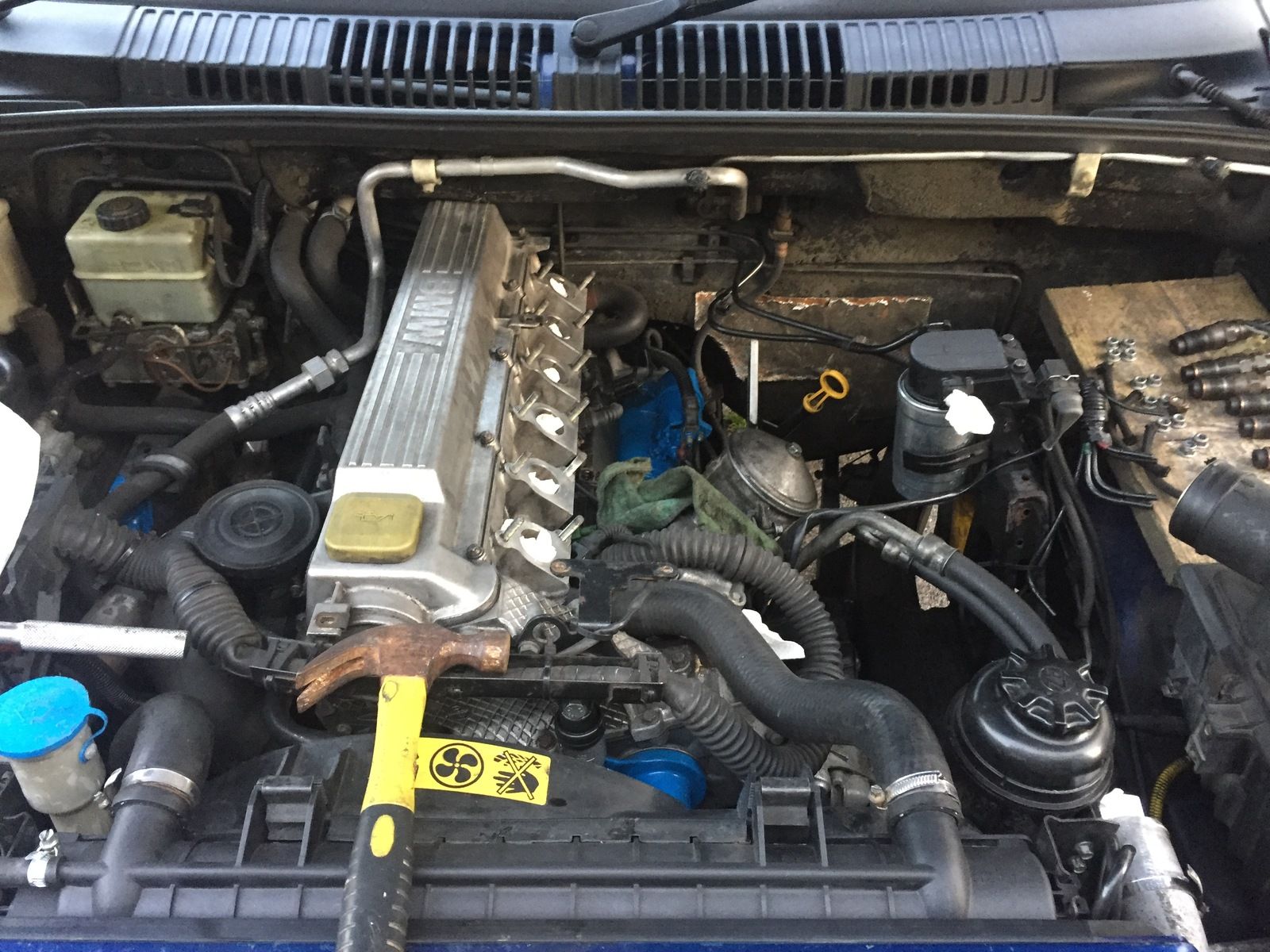

This scared me first time I dug this deep, I need it for my livelihood. Now not so bad

Disconnected battery got the plastics, ducting/pipes and manifold off.

Didn’t break a single gasket!

Beginners luck maybe...

Taken off all the fuel lines going to FIP, spill pipes and injectors out - No.5 seemed damp - Spillage perhaps.

Clear pipe off as has a kink in it I will cut off. Getting it back over the filter connector will be fun

warm water is the plan.

warm water is the plan.

Tomorrow I will read up and make a go of it.

One thing I’m not sure of is - how do you turn the crank by hand? Is it just socket and turn clockwise...

Is there anything else I can do to help the FIP while I’m at this stage?

Wammers told me day1 as a newb - read up, get the tools and get it done.

Thanks to Bagshot I have the tools, and thanks to everyone here I have the knowledge and skills (in theory

Not working tomorrow so plan is to try get it done accurately with whole day set aside just incase I start to snap things. Got home late today but made a start, surprised how much easier & quicker it is now I’m more familiar. being clean compared to the sh*t bucket I had at first makes things betterer.

This scared me first time I dug this deep, I need it for my livelihood. Now not so bad

Disconnected battery got the plastics, ducting/pipes and manifold off.

Didn’t break a single gasket!

Beginners luck maybe...

Taken off all the fuel lines going to FIP, spill pipes and injectors out - No.5 seemed damp - Spillage perhaps.

Clear pipe off as has a kink in it I will cut off. Getting it back over the filter connector will be fun

Tomorrow I will read up and make a go of it.

One thing I’m not sure of is - how do you turn the crank by hand? Is it just socket and turn clockwise...

Is there anything else I can do to help the FIP while I’m at this stage?