- Posts

- 10,639

- Location

- Oxfordshire

Right all work has now stopped on this engine.

I tried advancing the pump with no luck. Engine just didnt seem right so i took of the rocker cover to check that the rocker i had replaced was still fine.

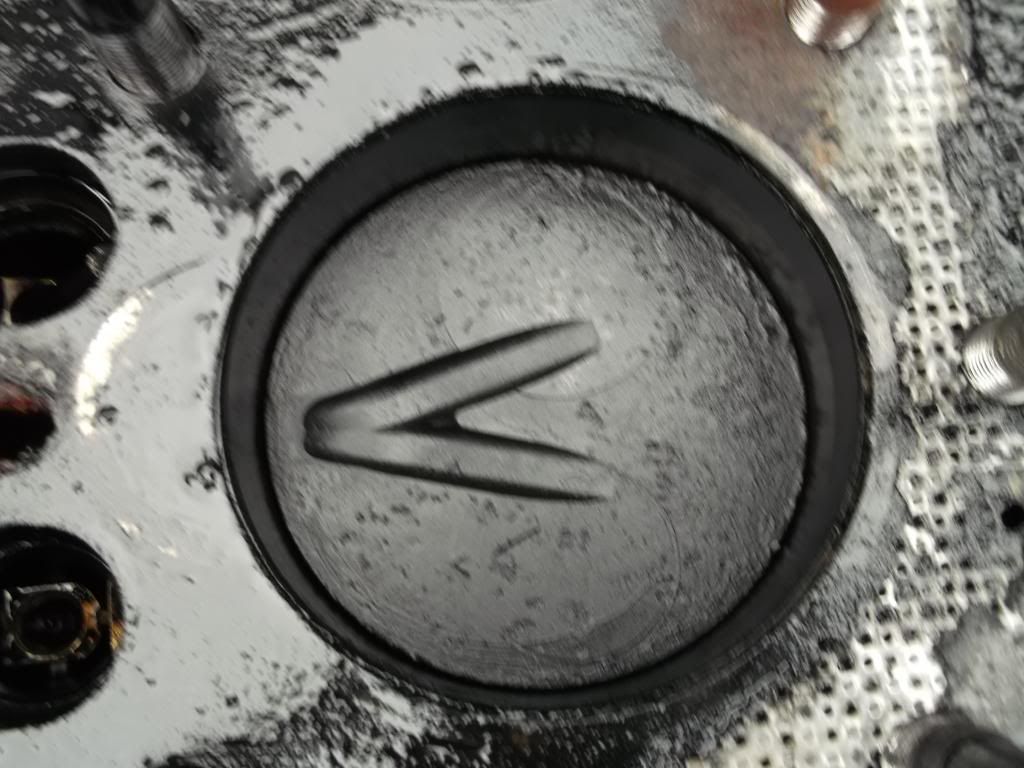

Then i found that another rocker had snapped in half!

When i first started having problems i discovered that rocker number 3 had snapped in half, i replaced this along with pump etc etc.

Now number 7 has snapped in half, i suspect something is seriously wrong inside the engine!