Right then a bit of a progress report,

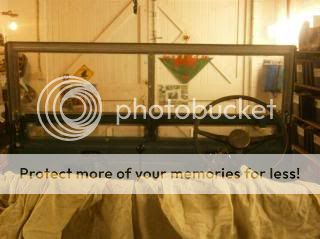

The seatbox was put in position ready to be bolted on but before that can be done, the sill needs to be added. The seatbox can probably be bolted up using the top holes but the 2 holes on either side are for bolts which are also for the sill so its easier to just do it all in one go I think.

The sill was put on. There are 2 bolts on the bulkhead head which have a plate welded to each bolt head which theoretically should make them captive but you may need to hold them so they dont turn. (this is made trickier by the fact they aren't bolt heads you can get a spanner on as they are flat). Put the inner most bolt in first and loosely put a nut on the end so it wont fall off. This is because the sill has a slot on one side so you can slot it over this bolt and then tighten the nut so it wont fall off. Then its a bit easier to do the next one.

The rear most bolts weren't being put in until the seatbox is getting bolted up so to help support the sill, a long thin bolt was pushed through the holes to keep it up. Before bolting them on, the sills got a coat of red oxide and then underseal.

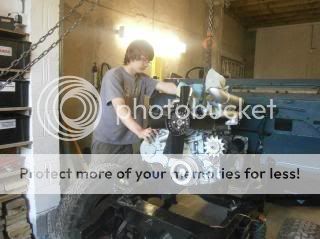

The pulley on the alternator was about 3/16"th too far forward out of alignment even at the position of the alternator where it was as far back as possible. So, solution was to take the pulley off and take it to stuart (who also welded the tub) who took off 3/16ths from the raised boss. Result is the pulleys are now in alignment properly

You may notice the alternator is a different colour, thats because we found one which sounded like it had better bearings and its smoother than the old one so that was fitted

Starter motor was wired up

As were the glow plugs

I put some diesel in the tank and me and my dad bled the fuel system up to the pump. We also had a go cranking the engine over using jump leads to try and bleed the injector pipes. This succeeded in turning the engine over (The starter motor works well

) but ended up melting the metal end of the jump lead.

Then I bolted the handbrake in which still needs connecting. Because the seat box was in position, i went underneath and slid it up from there

Today we were sorting wires out in the engine bay and put the screenwash mechanism back in. This works a treat, it has some bigger bore hose than it used to (6mm pipe and fittings) and the jets are pretty powerful things, going right over the windscreen and going halfway down the garage when we tested it

Also the wiper potor and wiper spindles have been bolted on and we've started putting foam soundproofing on the bulkhead