Well, first off, its not going to be a true expedition vehicle.... more of an 'adventure vehicle' (if it ever gets finished!).... but expedition sounds cooler.... When we bought the 110 in August it was visually in a poor state, having said that mechanically and structurally the previous owner had kept it well (just about), which is all that matters really!

Once we got her home we stripped out the back completely, took out the 2nd row seats, the rear side facing bench seats and what was left of the carpet. You will notice in the back the tubular frame from the bench seats is still there, I couldn't get it out without making more mess and as its doing no harm its there to stay! Also it accidentally makes for pretty good tie down points.

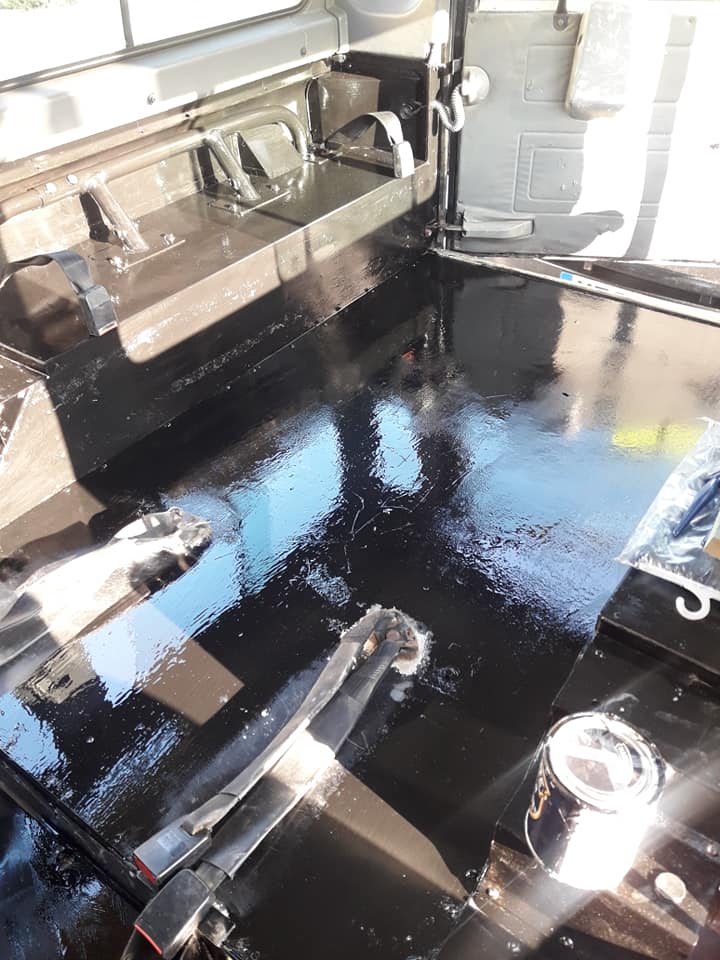

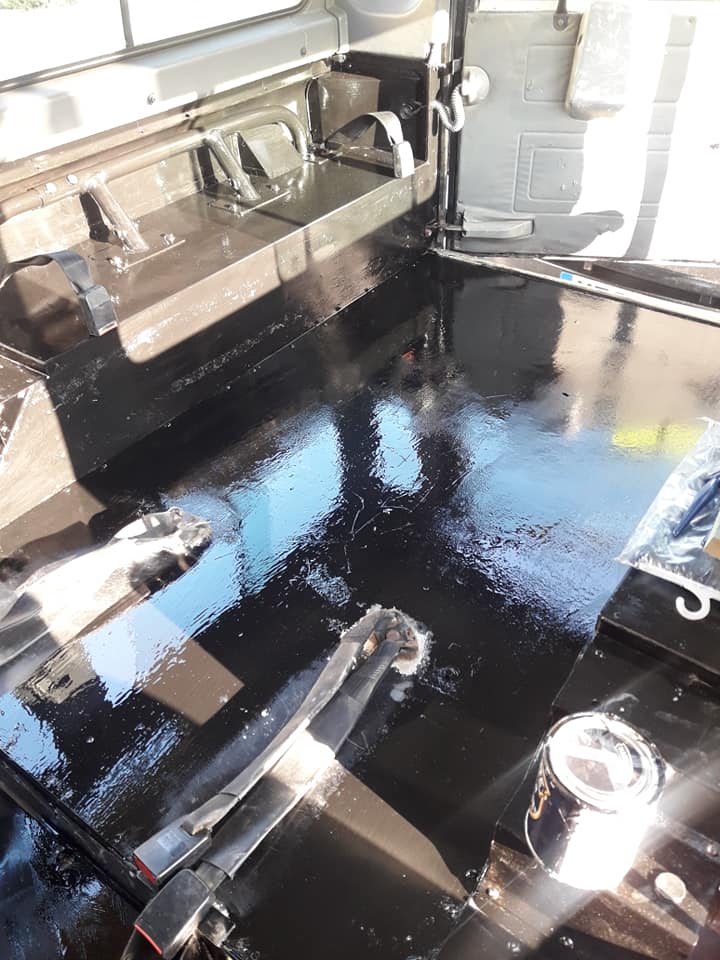

The next step was to sand down, wash out and generally clean 20 plus years of dog hair and detritus.... and yet more dust and dirt kept appearing. There were a few dents in the back which I levelled out with some filler for good measure.

I then painted the back with what felt like 100 coats of black hammerite. I think in the end it was only 4, but my god I never want to do that again. There is a lot said for spray paint! The quote of this phase happened when I shown the local mechanic who gave it a once over for me "Mechanically its sound, but *fudge* me the back smells like garden shed"

At this point I went away for a few weeks doing geological drilling and I noticed there was mud all on my new paint in the back, all up the side window and generally everywhere... turns out one of the bolts I removed from the rear seats I never filled and it was shooting through there.

The whole back was lined with DeadSheet Anti Drumming material, its a sort of sound proofing, but for the most part it just stops the drumming and rattling sound of the metal. It works really well and has made a huge difference.

On top of that the draw was made and fitted. Its MDF construction (few coats of varnish to try and keep the water at bay). Pull out table below for all the table needs, then a single draw above. I could not find longer draw runners so behind the draw there is also a lift up lid and an additional storage space there. The draw is about 15mm higher than the top of the wheel arches, I then made panels that fit ontop of the wheel arches which both make the top flush and level but also wedge the draw in place to stop it from moving.

This weekend we spent our time lining the top of the draw with 4mm rubber mat. Had a nightmare trying to get it to stick down. Tried several things but eventually stuck it down with copious amounts of clear silicon... remembering the old legendary mystical phrase "It it cannybe stuck with silicone, it canneybe stuck". There are a few corners that keep springing up, but I have some weights on them at the moment and will inspect it later in the week once its nice and dry. The exposed edges have been finished off with some metal edging strip.

The plan once it is dry is to fill in a few gaps (I was struggling as everything was so wet, once its dry it will be easier) then run a bead or two of silicone around the edge where the draw meets the side of the landy to stop any water tricking down the sides.

In the future I might also build a small (non structural) bulkhead behind the seats attached to the draw so things wont slide off the back of the draw and under the seats infront.

Its taken far too long to get to this point. But for the first time in 6 months progress is actually beginning to take shape.

Once we got her home we stripped out the back completely, took out the 2nd row seats, the rear side facing bench seats and what was left of the carpet. You will notice in the back the tubular frame from the bench seats is still there, I couldn't get it out without making more mess and as its doing no harm its there to stay! Also it accidentally makes for pretty good tie down points.

The next step was to sand down, wash out and generally clean 20 plus years of dog hair and detritus.... and yet more dust and dirt kept appearing. There were a few dents in the back which I levelled out with some filler for good measure.

I then painted the back with what felt like 100 coats of black hammerite. I think in the end it was only 4, but my god I never want to do that again. There is a lot said for spray paint! The quote of this phase happened when I shown the local mechanic who gave it a once over for me "Mechanically its sound, but *fudge* me the back smells like garden shed"

At this point I went away for a few weeks doing geological drilling and I noticed there was mud all on my new paint in the back, all up the side window and generally everywhere... turns out one of the bolts I removed from the rear seats I never filled and it was shooting through there.

The whole back was lined with DeadSheet Anti Drumming material, its a sort of sound proofing, but for the most part it just stops the drumming and rattling sound of the metal. It works really well and has made a huge difference.

On top of that the draw was made and fitted. Its MDF construction (few coats of varnish to try and keep the water at bay). Pull out table below for all the table needs, then a single draw above. I could not find longer draw runners so behind the draw there is also a lift up lid and an additional storage space there. The draw is about 15mm higher than the top of the wheel arches, I then made panels that fit ontop of the wheel arches which both make the top flush and level but also wedge the draw in place to stop it from moving.

This weekend we spent our time lining the top of the draw with 4mm rubber mat. Had a nightmare trying to get it to stick down. Tried several things but eventually stuck it down with copious amounts of clear silicon... remembering the old legendary mystical phrase "It it cannybe stuck with silicone, it canneybe stuck". There are a few corners that keep springing up, but I have some weights on them at the moment and will inspect it later in the week once its nice and dry. The exposed edges have been finished off with some metal edging strip.

The plan once it is dry is to fill in a few gaps (I was struggling as everything was so wet, once its dry it will be easier) then run a bead or two of silicone around the edge where the draw meets the side of the landy to stop any water tricking down the sides.

In the future I might also build a small (non structural) bulkhead behind the seats attached to the draw so things wont slide off the back of the draw and under the seats infront.

Its taken far too long to get to this point. But for the first time in 6 months progress is actually beginning to take shape.