You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Core plugs??

- Thread starter mini_kel

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Irishrover

Well-Known Member

- Posts

- 5,317

- Location

- La Trimouille, Vienne, France

Use a small chisel or old sturdy screwdriver and hammer to punch through the centre then prise them out. To refit, clean the bore of the cblock where it fits into, coat the outside diameter of the new plug with hermatite green or similar and just tap them in flush using a suitable drift or socket.

Hardest part is removing the stuff to access the plug, if it's at the back of the block, it's usually a case of pulling the engine forward or out although it has been known to drill a hole through the bulkhead for access instead and putting a "Patch" plate over it afterwards.

Core plugs are a pain, loads of work for what is a 5 miute job and a few bob for the plug.:Cry::Cry:

Hardest part is removing the stuff to access the plug, if it's at the back of the block, it's usually a case of pulling the engine forward or out although it has been known to drill a hole through the bulkhead for access instead and putting a "Patch" plate over it afterwards.

Core plugs are a pain, loads of work for what is a 5 miute job and a few bob for the plug.:Cry::Cry:

Irishrover

Well-Known Member

- Posts

- 5,317

- Location

- La Trimouille, Vienne, France

You may know how to fit them, but others on here may not have had the pleasure!!

Hard part is if you have to remove the exhaust manifolds & heat shields-they are a right pain in the a*se. If you haven't already done so, download RAVE from the link on the forum (Do a search).:behindsofa:

Hard part is if you have to remove the exhaust manifolds & heat shields-they are a right pain in the a*se. If you haven't already done so, download RAVE from the link on the forum (Do a search).:behindsofa:

I`ve removed the air con unit and power steering pump and found that it`s leaking from the front of the head, so i have ordered a head gasket set with new bolts. I will have the heads skimmed whilst they are off, will get some pics up over the weekend

Dont want to worry you but engines like these run without corrosion inhibitor, ie antifreeze usually kills them, the alloy and steel and cast iron all mix together to a terminal cocktail that rots and blocks everything up.

Might find you are off on a job, chasing faults are over the place.

It's a shame that bastids like this neglect their vehicles, and in this instance looking at the issues there are with water loss on this particular engine, odds on the reason there was fookal antifreeze in it is that it wont hold water and it's got fooked liners.

Engine runs lovely doesn`t miss or smoke at all and doesn`t have gunge in the cap, water is just seeping from head so hopefully the skim will sort it, not costing me any thing apart from the gaskets and my time and i got it at a really good price.

Ok lets be positive then, any service history that you can check up on, and when you have the heads off make sure it aint been roasted, check the bores for signs of it picking up, big tram lines vertical in the bores, and run a straight edge over the block.

Also with the heads off you will be able to see the camshaft and remove the followers, take them out, make sure the cam aint pitted and that the base of the followers are the same, they will probably be a bit dish shaped rather than flat like they should but thats normal wear, you will have to judge yourself if its exessive, but if they are pitted then it's fooked. They are a bit prone to cam wear.

If it's had regular oil changes with these bits off you will be able to tell by how much gunk has built up in the gulley. You will know what I mean when you get the plate off between the heads.

If it has a lot of cam wear wouldn`t it be noisy? Tapping?

Only start tapping once they can't adjust any more, saw one once where the guy had welded an extention onto the pushrod because the cam was shagged, was a taxi and the gulley was caked in gunge. Came in for a missfire, but the lobe of the cam had gone, worked for a week for him tho, I guess in taxi talk thats a load of dosh.

But you are in there anyway so it would be foolish not to check it.

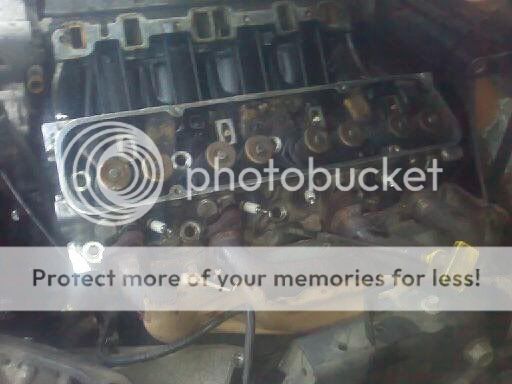

Finally got the head off today and to find that the gasket has let go on the front part of the water jacket everything else looks fine, will add some pics later tonight, cam looks fine with no pitting, cleaned block and head surfaces and thoroughly cheaked it and all is good, so will do the other head tomorrow

Finally got the head off today and to find that the gasket has let go on the front part of the water jacket everything else looks fine, will add some pics later tonight, cam looks fine with no pitting, cleaned block and head surfaces and thoroughly cheaked it and all is good, so will do the other head tomorrow

Good news.

Irishrover

Well-Known Member

- Posts

- 5,317

- Location

- La Trimouille, Vienne, France

Don't forget to replace the head bolts with new ones.

Irishrover

Well-Known Member

- Posts

- 5,317

- Location

- La Trimouille, Vienne, France

Too true. Nothing worse than fitting the heads back, only a couple of bolts to go and...ping!-strip it down and start again.

Irishrover

Well-Known Member

- Posts

- 5,317

- Location

- La Trimouille, Vienne, France

Good pic's. Did you have many probs removing the heat shields from the exhaust manifolds?

How did the engine manage to run with that CV joint down one of the cylinders?? lol :wtf::hysterically_laughi

How did the engine manage to run with that CV joint down one of the cylinders?? lol :wtf::hysterically_laughi

Similar threads

- Replies

- 42

- Views

- 5K