Tango91

Well-Known Member

- Posts

- 140

- Location

- Bideford, Devon

Howdy,

Thought I'd put down in writing the things that with hindsight would have made doing my body removal a lot easier.

I had some good advice from @steve24v on my project thread that covered a lot of this but I did find some things weren't necessary, or needed mentioning.

This probably has errors and omissions, I've drunk a lot of strong alcohol since then trying to forget.

It's probably worth saying that my D2 is TD5, manual, non-ACE, non AC that was originally on air but was on springs when I did this.

I would advise against starting this unless you have a diagnostic tool that can command the ABS modulator to power bleed the brakes afterwards.

Things you'll be wanting to disconnect, in no particular order except battery first:

Underbonnet electrical:

Cooling system:

How I lifted the body off:

I don't have access to a 2 post lift which would be the easy way to do it, but I did have access to 2 forklifts.

I cut lengths of 2x4 timber the right length to fit up underneath the length of the sills, there's handy pockets they will sit in allowing you to -mostly- not crush the plastic trims or the edges of the sills. Mostly.

Needless to say, go slowly and carefully and keep checking you're not pulling any wires or pipes or anything.

You should know:

The body is extremely rear heavy, consider removing the spare tyre, everything from the boot and possibly adding weight to the battery tray or inner front wings etc. I found the balance point was just in front of the rear outrigger mounts under the rear doors.

If you have ACE, Aircon or an auto transmission you'll probably have additional wires and/or hoses to disconnect that I didn't.

I think that's most of it, I'll edit if anyone comes up with something I've forgotten.

Reassembly is the reverse of removal, good luck!

Thought I'd put down in writing the things that with hindsight would have made doing my body removal a lot easier.

I had some good advice from @steve24v on my project thread that covered a lot of this but I did find some things weren't necessary, or needed mentioning.

This probably has errors and omissions, I've drunk a lot of strong alcohol since then trying to forget.

It's probably worth saying that my D2 is TD5, manual, non-ACE, non AC that was originally on air but was on springs when I did this.

I would advise against starting this unless you have a diagnostic tool that can command the ABS modulator to power bleed the brakes afterwards.

Things you'll be wanting to disconnect, in no particular order except battery first:

Underbonnet electrical:

- Take out the battery and throw it into the ocean

- Unbolt the terminal halfway up the negative battery lead from the body ground posts

- Unbolt the chassis ground strap (attached in front of the OSF shock tower) from the body ground posts

- remove the two large positive wires from the very front of the fuse box (circled red)

- remove the two smaller plugs and one terminal that i have no idea what they do (circled blue)

- loosen and unplug three connectors (circled green) under the coolant header tank, one grey multi, one orange multi, and a two pin black (easier if you lift the coolant tank out of the clips)

- unplug the MAF and air temperature sensors from the airbox pipework

- unplug the grey and red plugs from the ECU and the smaller grey connector that lives in there.

- unplug and remove the lights in the rear bumper

- unplug the towbar wiring if you have one (I didn't so I can't help you there)

- unplug the two front ABS sensors inside the front wings and poke the plugs back out of the grommet holes.

- Disconnect the reverse light switch from the left side of the transmission (manual) and the two plugs on the top of the transfer case for CDL and hi/lo range.

- disconnect the vacuum line from the brake booster nipple. I missed this and snapped mine off.

- The rest of the vacuum stuff is mounted to a bracket secured to the right side inner wing, inside the engine bay. You can access the 10mm nuts from the wheel well. Just unscrew it and poke it over by the intake manifold out of the way.

- disconnect the two large filler hoses for the diesel tank from the body, and the plastic breather tube with the squeezy disconnect clip thing

- remove the section of pipe with the MAF sensor that goes from the airbox to the turbo

- Unclip the power steering reservoir and flop it over onto the top of the engine leaving the hoses connected. I emptied mine on a recommendation then wished I had't bothered (if you have ACE then i can't help, sorry).

- If you had or have air suspension then there is a breather with a squeezy disconnect that feeds the compressor, it lives up behind the left rear light and the clip is at the bottom by the bumper.

- Remove the two rubber hoses that go between the metal turbo pipe and the intercooler, and the intercooler and the intake manifold/EGR pipe.

- Disconnect the union on the clutch pipe where it goes from steel to plastic pipe, this is near the clutch master cylinder just in front of the bulkhead

- Disconnect the handbrake cable and pull the whole lot out the bottom of the hole in the transmission tunnel

- You may want to vacuum out the brake fluid in the reservoir to stop it all draining out

- Remove the banjo bolts on the front calipers, unclip the brake flexi hoses from the brackets on the spring perches, and tie the flexi hoses up out of the way

- Disconnect the 2 rear brake pipes from the short flexis in the passenger side footwell where they jump across to the chassis. (Good luck with that)

- The front grille

- The front bumper and steel support structure NOT including the aluminium crumple members

- the outer and inner rear bumper, held on to the rear of the chassis with 2 m12 bolts

- The plastic guards ahead of the front shock towers( under the inner front wings) get in the way and scrape on the way up and down, it's easy to remove them with 3 8mm head screws each side

Cooling system:

- Drain the cooling system using the drain plug on the bottom of the metal pipe in front of the crank pulley

- Disconnect the two heater matrix hoses at the bulkhead fittings by the intake manifold

- Remove the horns from the front valance to access the nuts on the brackets that secure the top of the radiator and intercooler

- Remove the cooling fan before trying to get the fan shroud or radiator out (hit the nut counterclockwise with a hammer and punch if you don't have a fan wrench)

- Remove the fan shroud

- Remove the coolant hoses that go from the thermostat housing to the radiator, and the radiator top hose

- Lift the radiator/intercooler out of the mounting holes in the chassis

- Remove the gear lever & transfer case lever from inside the cab, there are plenty of guides on how to dig down to them

- Steering linkage: douse it in penetrating fluid, take out the 10mm bolt that attaches to the bottom of the steering shaft, loosen the clamp bolt on the other end and hammer it off the splines, towards the steering box, it telescopes into itself just enough

- Front carpets (to access the front outrigger body mount bolts)

- Front seats (don't forget the connectors under the seats for the seatbelt explosive tensioners)

- The centre console and interior plastics over and round the transmission tunnel

- rear brake lines except at the fittings in the front passenger side footwell

- rear ABS sensors, the loom is fixed to the chassis and is disconnected at the engine end

- fuel lines except the 3 attached to the filler port

- the PAS hoses, just unclip the tank and secure it out of the way of the inner wings

- The compressor and all associated pipework goes with the chassis, except the breather which is disconnected by the rear bumper under the left tail light.

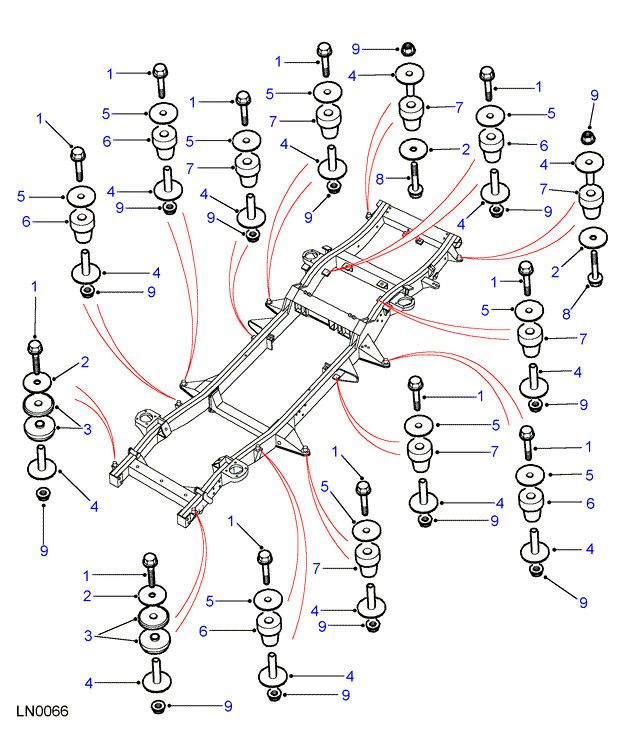

- at the very front of the body, accessed from in front of the car behind the front grille

- at the bottom of the bulkhead via the engine bay (you'll need a friend)

- the front outriggers, access to the bolt heads via small holes in the front footwells by the door hinges

- under the front seats, directly above the chassis rails level with the handbrake drum

- the rear outriggers, bolts are accessed from underneath the car, or from the rear wheel wells if the rust has gotten that bad

- The boot floor under/behind the rear seats (you'll need a friend)

- The very rear of the chassis, just ahead of the bumper moiunts, access to the bolts from underneath, the body has towers with captive nuts inside. I believe these bolts are longer than the rest of them

How I lifted the body off:

I don't have access to a 2 post lift which would be the easy way to do it, but I did have access to 2 forklifts.

I cut lengths of 2x4 timber the right length to fit up underneath the length of the sills, there's handy pockets they will sit in allowing you to -mostly- not crush the plastic trims or the edges of the sills. Mostly.

Needless to say, go slowly and carefully and keep checking you're not pulling any wires or pipes or anything.

You should know:

The body is extremely rear heavy, consider removing the spare tyre, everything from the boot and possibly adding weight to the battery tray or inner front wings etc. I found the balance point was just in front of the rear outrigger mounts under the rear doors.

If you have ACE, Aircon or an auto transmission you'll probably have additional wires and/or hoses to disconnect that I didn't.

I think that's most of it, I'll edit if anyone comes up with something I've forgotten.

Reassembly is the reverse of removal, good luck!

Last edited: