Ok, so I'll apologise in advance for the long thread, but some background may be relevant... Plus if you're bored, it will give you a laugh and make your day seem a whole lot better!

I purchased my 2005 TD6 Vogue SE in June 21 having pondered for a long while. Diesel went against the grain a little as at heart I'm a petrolhead, but half-sensible economy was necessary for my daily commute and rising fuel costs. I've had a few V8's - from a Rover SD1 3500 to a couple of RR classics 3.5 &3.9, a 3.9 S1 Disco and a 4.6 P38 that I still have but hasn't ventured onto tarmac for a decade due to the crippling 11-12mpg! (Even has LPG, but that achieved about 9mpg) When I 'retired' the P38, I picked up a Jag XJ8 4.0 for £350 which I used as a daily commute for about 3 years (until the welding cost became prohibitive) - this was rapid and yet averaged 20mpg on my daily commute of 26 miles. A TD6 thus seemed just the ticket and should easily return >20mpg... I would have liked the TDV8 but the thought of donating over £500 a year to Dick Turpin was little short of grossly offensive.

At £4k I purchased at the low end of the market at the time for the year/spec for a pretty clean example with everything apart from aircon and phone working (£500 reduction from asking). Reasonable mileage at 134k, but no service history. Gearboxes were always a concern given all the issues, but drove ok and I averaged close to 30mpg on the 200 mile trip home (bit of urban, M3, A303, A35, M5 etc. My work commute was averaging about 26-27mpg over last summer. Truck has no towbar and although I will need one at some point, this seemed a plus.

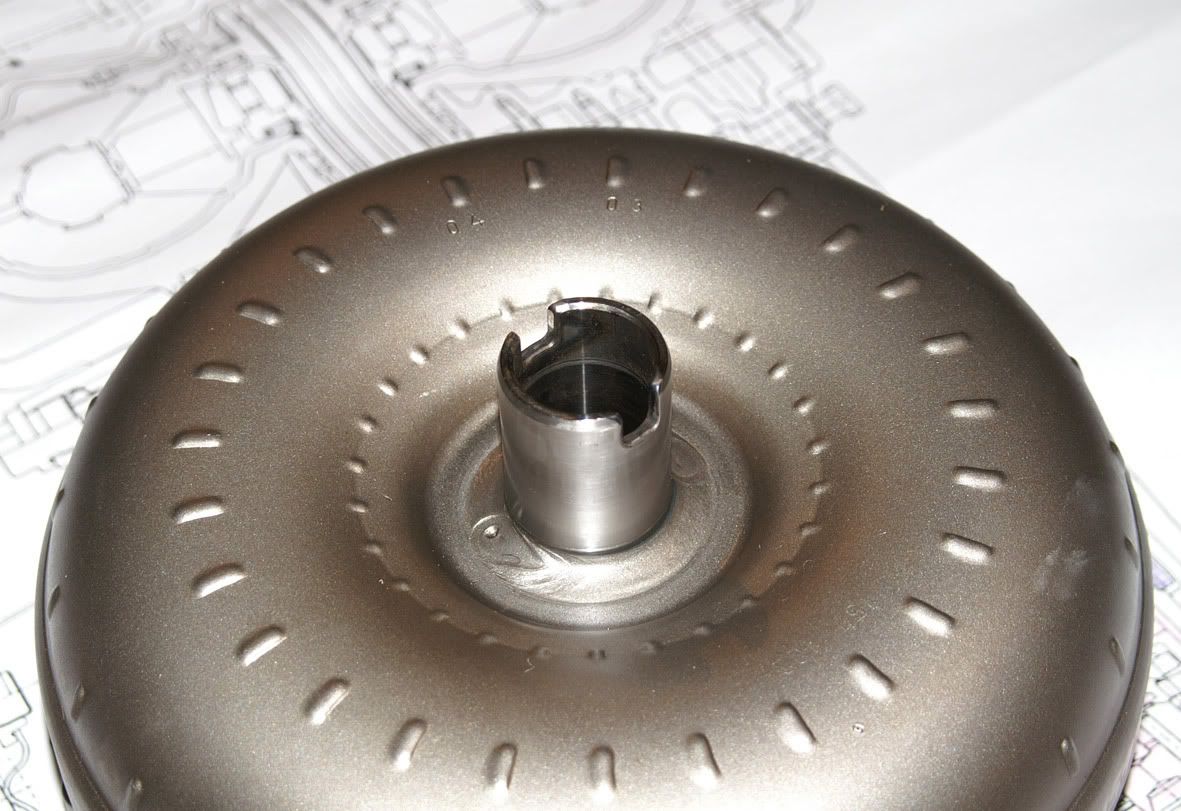

All was well into the autumn, but due to the lack of service history, I worked my way through sevicing tasks and a gearbox oil change was on the list along with belts/belt tensioners as a squeak was evolving and mpg was dropping. Time and cashflow were tight, so I planned a tranmission oil and filter change for when I would be off work for 10 days over Christmas 2021. By December however, mpg had dropped to 19mpg and some gremlins were evident. Shifting was fine and no discernable sliping in gears, but there was clearly an issue with lockup clutch - even driving on the level at 55mph would see a 500-600 rpm rise and a 'shift' down after 5 seconds of applying even slight pressure on the throttle. It also seems to be revving higher in normal driving before shifting. The second issue was more unusual - when driving downhill with foot off the throttle, every 40-50 seconds the engine revs would drop from the 'in gear' 1200-1500 to idle (800) and then after a further 20 seconds or so would go back much like releasing a clutch on a manual. As the truck drove fine when manually shifting, I figured the Torque Convertor (or more specifically the lock-up clutch) was the most likely culprit to start with although coast clutches etc in transmission were suspects too for the second issue. Funds were tight (as I suspect for most), so as I already had filter and oil ready, I purchased a second hand TC. Timing was unfortunate as I didn't get this until just before New Year, so I arranged with a local garage who MoT's our cars, to pull the transmission and replace oil, filter and TC in early January whilst I was back at work. Total cost was just over £630 to include garage labour, the oil, filter and s/h TC that I provided.

Having picked up from the garage and resumed the weekly commute, it became apparant that the issues remained, the 'TC' issue was slightly better and mpg improved marginally, but the issue of 'dropping in/out of gear' on downhill running persisted.

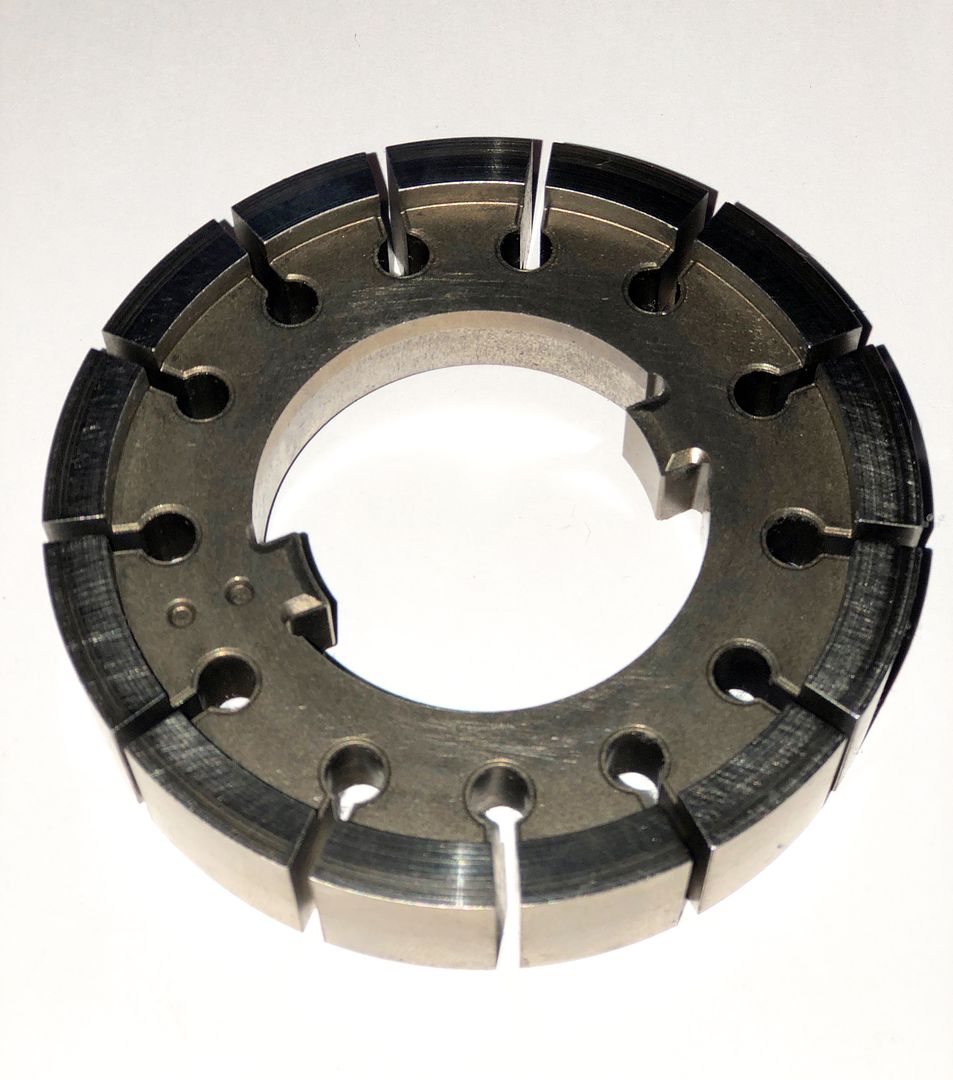

This is where sanity took a temporary holiday... I decided to do something on my bucket/curiosity list - I'd rebuild the transmission myself! How hard can it be? What could possibly go wrong? Lots of online information on threads here and on YouTube... I have a naturally curious/diagnostic thought process, so I was up for the challange - the truck was duly reversed onto ramps, sorn'ed and the transmission and transfer box relocated to the workbench. I had MoT'd taxed and insured an old Daihatsu Sportrak I'd had laid up for a few years back in September for my son to learn to drive, so this would be the backup transport for commute. Time was thus not pressured. Lots of reading, watching, downloading followed - along with procurement of some additional tools (That monster snap ring is a mission!). Having methodically stripped, cleaned and inspected, nothing obviously conclusive was found, quite a bit of grey muck was cleaned as expected, but on the whole not so bad. I wasn't massively surprised as this was essentially a working transmission apart from the 'high end' gremlins. Doubts about the TC persisted, but were pushed to the back of my mind. Over the next couple of months, I collected necessary seals, filters, more oil, clutches and TC solenoid. The TC solenoid appeared ok, but just in case it was intermittent or didn't work when warm etc it seemed prudent to swap out.

I have a naturally curious/diagnostic thought process, so I was up for the challange - the truck was duly reversed onto ramps, sorn'ed and the transmission and transfer box relocated to the workbench. I had MoT'd taxed and insured an old Daihatsu Sportrak I'd had laid up for a few years back in September for my son to learn to drive, so this would be the backup transport for commute. Time was thus not pressured. Lots of reading, watching, downloading followed - along with procurement of some additional tools (That monster snap ring is a mission!). Having methodically stripped, cleaned and inspected, nothing obviously conclusive was found, quite a bit of grey muck was cleaned as expected, but on the whole not so bad. I wasn't massively surprised as this was essentially a working transmission apart from the 'high end' gremlins. Doubts about the TC persisted, but were pushed to the back of my mind. Over the next couple of months, I collected necessary seals, filters, more oil, clutches and TC solenoid. The TC solenoid appeared ok, but just in case it was intermittent or didn't work when warm etc it seemed prudent to swap out.

Work is always manic in the spring and coupled with other usual life challanges, it was June before I rebuilt and refitted. It didn't work - no drive whatsoever! Ran through gears, double checked connections, oil level etc. Nothing.

At this point I think I made a fundamental mistake, by not doing any diagnostics or having any faith in my rebuild. I ASSUMED that I had made an error during the rebuild as I hadn't done one previously. Despite all the double checking, measuring etc. There were no nasty noises and when on the bench, rotating the input shaft had rotated the output shaft. However, faced with the time required to strip again, another seal kit etc, I bailed - I put back on the bench for a rainy day and I purchased a second hand transmission. I fitted a new filter to this and fitted to truck, filled with more fresh oil and hey ho, everything worked. This was late summer and I needed an MoT before anything else, so a quick check around and MoT booked. Passed with flying colours.

Ok, so commute/driving... Problem of shifting still persists, probably even more appartant as this transmission seems to have a slightly 'lazy' shift from 3rd in that it holds 3rd far too long 3100rpm! (Manual driving is fine and shift then is instant whatever the RPM.) MPG is now about 18. The issue with 'dropping out' of gear on downhill runs has gone completely. Given that the truck was sat unused from January to September, I had checked for binding brakes etc already, but have revisited and no issues found nor excess heat from wheels/hubs etc after a long run. I thus concluded that the s/h torque convertor was a mistake so I purchased a refurbished one, more oil.... Here we go again!

Last Sunday, I decided to bite the bullet and went through the routine again - shafts, transfer box and frame out, transmission out, but this time I left oil in as it's only done a few weeks and this would be a 'quick' remove and refit... (Bearing in mind I'm lifting this manually under the truck, this was perhaps a mistake as about 6kg heavier with oil!) It took about 3 hours to remove everything and swap over the torque convertors - I half-filled the new one with clean oil so there would be less topping up. I got the transmission back on eventually (a bit of a mission due to weight, getting off ground on to chest and lifting into position/locating) and supported with a jack and two loose bolts as it was getting too dark. I took Friday off work and resumed fitting. Yesterday morning I topped up the oil, reconnected the starter and fired up... No drive. Exactly the same as the rebuilt transmission. No nasty noises, oil is to fill plug.

I left alone at that point yesterday for sanity, but revisited a few times today. Starts and runs but no drive and no hint of drop in revs when selctor is in D or R, no faults, hi/lo selects in neutral (as expected as not directly linked). Checked selecter and electric cable plug (removed and refitted 4-5 times). Oil pressure was the only possibility, so with engine running and in neutral, I carefully lostened and removed the oil cooler pipes, expecting an explosion of oil. Nothing. Switched off and pumped 1/8L of Dextron VI into each of the oil cooler inlet/outlet of the transmission, thinking the pump isn't priming. Restarted, ran through gears, no difference. Selected neutral, back under and removed oil hoses again (even more carefully!) - nothing! So this time I squirted some oil in whilst running with second hose held on, still nothing. I'm missing something.

12 months on, one issue resolved and second currently unknown, but facing a 4th removal and refit!!! I wish I had purchased some shares in oil before I started. I really don't believe there's a fault with the transmission as it was working and has only move 2' away before being refitted. There probably isn't anything wrong with the rebuilt one either, but I dare not complicate matters by traing that again yet... I also don't think the TC can be faulty - or certainly not faulty enough not to turn the box at all. Oil friction alone should surely create some 'bite'? Everything leads me to think that the oil pump isn't priming, but if that's the case, the more I try isn't going to help, but likely won't do the pump any good either? When I rebuild the first one, I 'liberally' coated everything in oil as per guide, but I suspect not liberally enough. This one arrived on a pallet with no oil and had probably been out of a vehicle for ages, but when I first fitted it worked first time. This time, the oil has remained in and it doesn't work. Bizarre.

So, I have a couple of questions:

1) has anyone had this much fun with their Rangie transmission?

2) any ideas to 'persude' the pump to prime - ideally without pulling the transmission again?

Cheers...

I purchased my 2005 TD6 Vogue SE in June 21 having pondered for a long while. Diesel went against the grain a little as at heart I'm a petrolhead, but half-sensible economy was necessary for my daily commute and rising fuel costs. I've had a few V8's - from a Rover SD1 3500 to a couple of RR classics 3.5 &3.9, a 3.9 S1 Disco and a 4.6 P38 that I still have but hasn't ventured onto tarmac for a decade due to the crippling 11-12mpg! (Even has LPG, but that achieved about 9mpg) When I 'retired' the P38, I picked up a Jag XJ8 4.0 for £350 which I used as a daily commute for about 3 years (until the welding cost became prohibitive) - this was rapid and yet averaged 20mpg on my daily commute of 26 miles. A TD6 thus seemed just the ticket and should easily return >20mpg... I would have liked the TDV8 but the thought of donating over £500 a year to Dick Turpin was little short of grossly offensive.

At £4k I purchased at the low end of the market at the time for the year/spec for a pretty clean example with everything apart from aircon and phone working (£500 reduction from asking). Reasonable mileage at 134k, but no service history. Gearboxes were always a concern given all the issues, but drove ok and I averaged close to 30mpg on the 200 mile trip home (bit of urban, M3, A303, A35, M5 etc. My work commute was averaging about 26-27mpg over last summer. Truck has no towbar and although I will need one at some point, this seemed a plus.

All was well into the autumn, but due to the lack of service history, I worked my way through sevicing tasks and a gearbox oil change was on the list along with belts/belt tensioners as a squeak was evolving and mpg was dropping. Time and cashflow were tight, so I planned a tranmission oil and filter change for when I would be off work for 10 days over Christmas 2021. By December however, mpg had dropped to 19mpg and some gremlins were evident. Shifting was fine and no discernable sliping in gears, but there was clearly an issue with lockup clutch - even driving on the level at 55mph would see a 500-600 rpm rise and a 'shift' down after 5 seconds of applying even slight pressure on the throttle. It also seems to be revving higher in normal driving before shifting. The second issue was more unusual - when driving downhill with foot off the throttle, every 40-50 seconds the engine revs would drop from the 'in gear' 1200-1500 to idle (800) and then after a further 20 seconds or so would go back much like releasing a clutch on a manual. As the truck drove fine when manually shifting, I figured the Torque Convertor (or more specifically the lock-up clutch) was the most likely culprit to start with although coast clutches etc in transmission were suspects too for the second issue. Funds were tight (as I suspect for most), so as I already had filter and oil ready, I purchased a second hand TC. Timing was unfortunate as I didn't get this until just before New Year, so I arranged with a local garage who MoT's our cars, to pull the transmission and replace oil, filter and TC in early January whilst I was back at work. Total cost was just over £630 to include garage labour, the oil, filter and s/h TC that I provided.

Having picked up from the garage and resumed the weekly commute, it became apparant that the issues remained, the 'TC' issue was slightly better and mpg improved marginally, but the issue of 'dropping in/out of gear' on downhill running persisted.

This is where sanity took a temporary holiday... I decided to do something on my bucket/curiosity list - I'd rebuild the transmission myself! How hard can it be? What could possibly go wrong? Lots of online information on threads here and on YouTube...

Work is always manic in the spring and coupled with other usual life challanges, it was June before I rebuilt and refitted. It didn't work - no drive whatsoever! Ran through gears, double checked connections, oil level etc. Nothing.

At this point I think I made a fundamental mistake, by not doing any diagnostics or having any faith in my rebuild. I ASSUMED that I had made an error during the rebuild as I hadn't done one previously. Despite all the double checking, measuring etc. There were no nasty noises and when on the bench, rotating the input shaft had rotated the output shaft. However, faced with the time required to strip again, another seal kit etc, I bailed - I put back on the bench for a rainy day and I purchased a second hand transmission. I fitted a new filter to this and fitted to truck, filled with more fresh oil and hey ho, everything worked. This was late summer and I needed an MoT before anything else, so a quick check around and MoT booked. Passed with flying colours.

Ok, so commute/driving... Problem of shifting still persists, probably even more appartant as this transmission seems to have a slightly 'lazy' shift from 3rd in that it holds 3rd far too long 3100rpm! (Manual driving is fine and shift then is instant whatever the RPM.) MPG is now about 18. The issue with 'dropping out' of gear on downhill runs has gone completely. Given that the truck was sat unused from January to September, I had checked for binding brakes etc already, but have revisited and no issues found nor excess heat from wheels/hubs etc after a long run. I thus concluded that the s/h torque convertor was a mistake so I purchased a refurbished one, more oil.... Here we go again!

Last Sunday, I decided to bite the bullet and went through the routine again - shafts, transfer box and frame out, transmission out, but this time I left oil in as it's only done a few weeks and this would be a 'quick' remove and refit... (Bearing in mind I'm lifting this manually under the truck, this was perhaps a mistake as about 6kg heavier with oil!) It took about 3 hours to remove everything and swap over the torque convertors - I half-filled the new one with clean oil so there would be less topping up. I got the transmission back on eventually (a bit of a mission due to weight, getting off ground on to chest and lifting into position/locating) and supported with a jack and two loose bolts as it was getting too dark. I took Friday off work and resumed fitting. Yesterday morning I topped up the oil, reconnected the starter and fired up... No drive. Exactly the same as the rebuilt transmission. No nasty noises, oil is to fill plug.

I left alone at that point yesterday for sanity, but revisited a few times today. Starts and runs but no drive and no hint of drop in revs when selctor is in D or R, no faults, hi/lo selects in neutral (as expected as not directly linked). Checked selecter and electric cable plug (removed and refitted 4-5 times). Oil pressure was the only possibility, so with engine running and in neutral, I carefully lostened and removed the oil cooler pipes, expecting an explosion of oil. Nothing. Switched off and pumped 1/8L of Dextron VI into each of the oil cooler inlet/outlet of the transmission, thinking the pump isn't priming. Restarted, ran through gears, no difference. Selected neutral, back under and removed oil hoses again (even more carefully!) - nothing! So this time I squirted some oil in whilst running with second hose held on, still nothing. I'm missing something.

12 months on, one issue resolved and second currently unknown, but facing a 4th removal and refit!!! I wish I had purchased some shares in oil before I started. I really don't believe there's a fault with the transmission as it was working and has only move 2' away before being refitted. There probably isn't anything wrong with the rebuilt one either, but I dare not complicate matters by traing that again yet... I also don't think the TC can be faulty - or certainly not faulty enough not to turn the box at all. Oil friction alone should surely create some 'bite'? Everything leads me to think that the oil pump isn't priming, but if that's the case, the more I try isn't going to help, but likely won't do the pump any good either? When I rebuild the first one, I 'liberally' coated everything in oil as per guide, but I suspect not liberally enough. This one arrived on a pallet with no oil and had probably been out of a vehicle for ages, but when I first fitted it worked first time. This time, the oil has remained in and it doesn't work. Bizarre.

So, I have a couple of questions:

1) has anyone had this much fun with their Rangie transmission?

2) any ideas to 'persude' the pump to prime - ideally without pulling the transmission again?

Cheers...